Standard coupling sleeve, also known as semi bridge coupling sleeve, has a section of the bridge without a thread in the middle. The threaded part of the drill pipe cannot be screwed through the bridge part of the coupling, and the end of the thread can closely adhere to the casing bridge zone. Standard coupling sleeve is particularly suitable for high-torque drilling rigs. Most rope thread (R thread) and trapezoidal thread (T thread) coupling sleeves are with half-bridge type.

Contact Now

Elevate Your Drilling Game with R35 Coupling Sleeves: Unrivaled Precision and DurabilityUnleash the power of precision and durability in your drilling endeavors with our top-of-the-line R35 Coupling Sleeves.

Contact Now

Unleash Precision and Power with R38 Coupling SleevesElevate your drilling operations to new heights with our state-of-the-art R38 Coupling Sleeves.

Contact Now

R25 Coupling Sleeves: Seamless Connections for Efficient DrillingIn the realm of drilling excellence, the R25 Coupling Sleeves stand as a testament to precision engineering and unwavering reliability.

Contact Now

Master T45 Coupling Sleeves for Precision Drilling and Outstanding PerformanceIn the realm of drilling, T45 Coupling Sleeves achieve exceptional precision and reliability, injecting robust power into your projects.

Contact Now

Drill Coupling Sleeves:In drilling applications, coupling sleeves are used to connect and join drill rods.

Contact Now

Optimize Your Drilling Efficiency with R32 Coupling SleevesUnlock unparalleled performance in your drilling operations with our cutting-edge R32 Coupling Sleeves.

Contact Now

Coupling Sleeve is a high-performance coupling sleeve designed for mechanical systems, dedicated to providing outstanding durability and reliability.

Contact Now

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's ChoiceUnlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters.

Contact Now

Coupling sleeves are essential components in rock drilling, serving to connect various segments of the drill string, such as shank adapters, drill rods, and drill bits. They ensure continuity in the drill string and facilitate the efficient transfer of rotational and percussive forces. Here's a detailed overview of coupling sleeves and the types available:Coupling Sleeves Overview1. DefinitionCoupling sleeves are cylindrical components with internal threads used to join two sections of a drill string, such as a shank adapter to a drill rod or two drill rods.

Contact Now

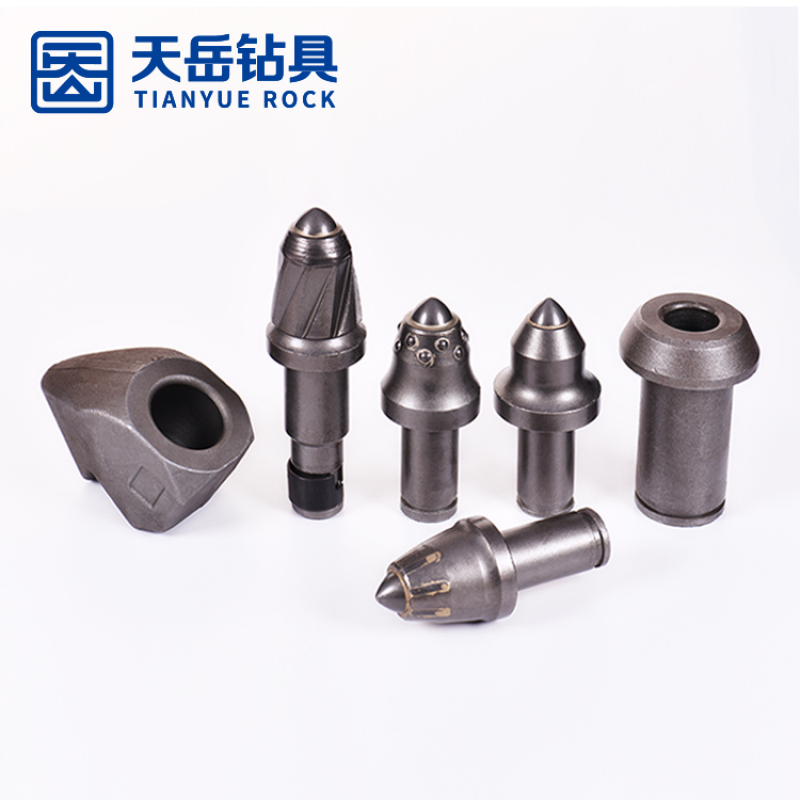

Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDCoal cutter teeth sleeves are components used in coal cutting machinery to protect and enhance the performance of the cutting tools, commonly known as coal cutter teeth or picks. These sleeves play a crucial role in the coal mining industry, where specialized equipment is used to extract coal from underground or open-pit mines.

Contact Now

Product numberPick length(mm)Length of head(mm)Pick hanldle diameter(mm)PDC insert diameter(mm)Pick head diameter(mm)U8215280301450U8414270301650U8516185301450U92195101351655U9418390351955U9518288352455U17021589432264D4714065302350D12014368301655D13515580381963Advantages of TianYue Mining Bits:* Quick-change connection design for easy replacement* Forging technology provides high strength properties.* Unique body shape designed to maximize efficiency and cuts*Our engineering team can work with your engineering and also make sample products, to make your ideal product.43mm/35mm(1.70'' /

Contact Now

Exceptional Design and Efficient PerformanceShank Adapter HC HBM stands out as a premier choice in rock drilling tools, delivering exceptional solutions for challenging rock formations with its exquisite design and efficient performance.

Contact Now

Features:Threaded Drill Bits are essential tools used in various construction projects such as tunneling, underground mining, open pit mining, anchoring, and other large-scale construction projects. These bits come in different types including regular, retract, and reaming, each serving specific purposes. One of the key advantages of Threaded Drill Bits is their strong button-fixing ability. This feature ensures that the buttons or cutting elements of the drill bits remain securely in place, even under heavy use.

Contact Now

Applications:Retrac button bits find applications in various drilling operations, including mining, quarrying, tunneling, and construction. They are suitable for drilling blast holes, anchor holes, exploration drill holes, and other rock drilling tasks.Face Design:The face design of retrac button bits may include options such as flat face, drop center, concave, or convex designs. The choice of face design depends on specific drilling requirements and the type of rock being encountered.Sizes and Variations:Retrac button bits come in various sizes to accommodate different drilling requirements.

Contact Now

Attachment Mechanism:The conical pick sleeve serves as a connecting element between the conical pick and the drilling equipment. It is designed to securely hold and attach the conical pick to the drill rod or other cutting apparatus.Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDMaterial:Conical pick sleeves are typically made from durable and wear-resistant materials, ensuring longevity and performance in challenging drilling or cutting environments.

Contact Now

In addition to the T45 button bit for hard rock drilling mentioned earlier, we also offer a wide range of top hammer hard rock mining tools, including drilling bits, drill rods, shank adapters for drills, and coupling sleeves.

We take pride in providing the best drill bits for hard rock applications.Our selection includes various hard rock drill bits with different specifications to meet your specific needs. Thread options available include R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, among others.

Contact Now

Thread Type:The "ST" in ST58 typically refers to a specific thread type, but it's important to note that variations in thread standards may exist. The "58" denotes the diameter of the thread in millimeters. The thread type is crucial for compatibility with various drilling equipment, ensuring a secure and efficient connection.Retrac Design:The retrac design is a distinctive feature of these bits. The cutting buttons on the bit are retractable, allowing them to adapt to changing rock hardness.

Contact Now

A retrac button bit is a type of drill bit designed for rock drilling applications, especially in challenging and abrasive geological conditions. The term "retrac" refers to a specific design feature where the cutting buttons on the bit are retractable, meaning they can move inward into the bit body.

Contact Now

Features:The Top Hammer Reaming Drilling Bit is renowned for its exceptional wear resistance, making it highly effective on medium-hard to hard abrasive rock formations. Its design includes spherical tungsten carbide inserts, which provide a strong defense against carbide fracture. 3.

Contact Now

The R38 Extension Rod 1220mm 1830mm Drill Rod is compatible with various drilling machines, making it a versatile choice for different applications. Whether you are working on construction projects, mining operations, or geotechnical investigations, this drill rod will meet your requirements with ease.

Additionally, the R38 Extension Rod features a convenient and easy-to-use design.

Contact Now

The T45-D76mm retract button bits are suitable for drilling in various types of rock formations, including hard and abrasive formations. They are widely used in mining operations, tunneling projects, and geotechnical drilling.

These button bits are precision engineered to deliver optimal cutting performance and fast penetration rates. They have a unique face design that ensures efficient rock fragmentation and improved drilling productivity.

To ensurethe longevity and performance of the T45-D76mm retract button bits, proper maintenance and care are necessary.

Contact Now

With an expert group in the field of geotechnical engineering and metal materials as the core, and based on advanced production technology, the company focuses on the exploration of the field of geotechnical engineering tools, and constantly pursues quality perfection and product innovation to satisfy users in geotechnical engineering.

Contact Now

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body.

Contact Now