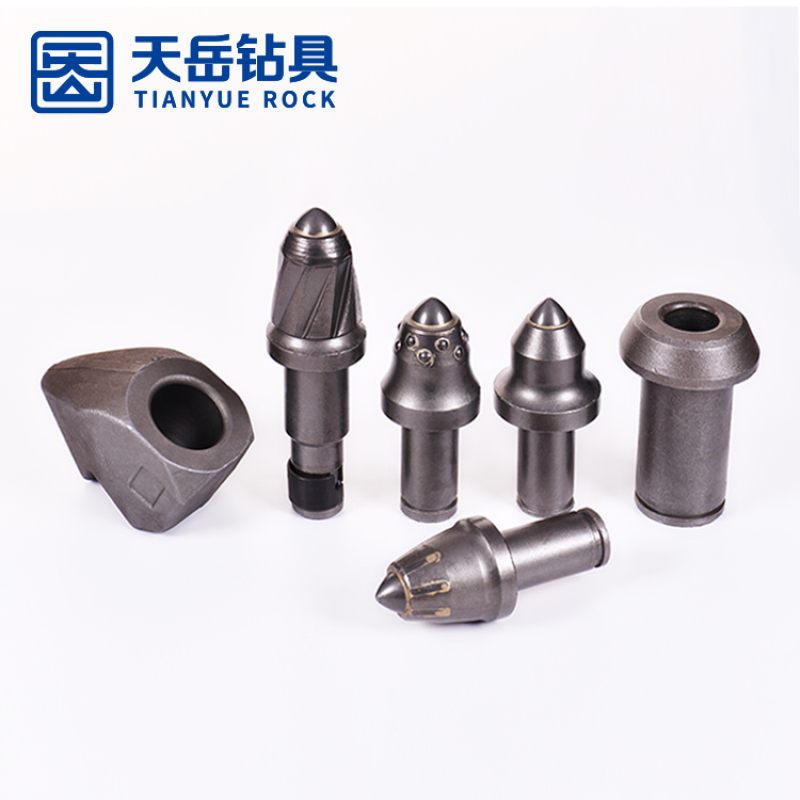

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body.

Contact Now

Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDCoal cutter teeth sleeves are components used in coal cutting machinery to protect and enhance the performance of the cutting tools, commonly known as coal cutter teeth or picks. These sleeves play a crucial role in the coal mining industry, where specialized equipment is used to extract coal from underground or open-pit mines.

Contact Now

20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Road milling tools, also known as road milling bits or asphalt milling cutters, are cutting tools used in road milling machines or cold planers. These tools are essential in the process of removing and reclaiming the existing pavement surface on roads and highways. Road milling is a common method for resurfacing, rehabilitation, or upgrading road surfaces. Here are key features and information about road milling tools:Design:Road milling tools are designed to break and remove the asphalt or concrete surface of roads.

Contact Now

Cutting Structure:Road mining tools have a cutting structure, typically made of carbide or other wear-resistant materials, to effectively mill or cut through asphalt, concrete, or other road surfaces.Variety of Shapes:These tools come in various shapes, including bits, picks, or teeth, depending on the specific application and the type of road milling machine used.20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Material Composition:The cutting tips or inserts on road mining tools are often made from materials such as tungsten carbide for durability and resistance to we

Contact Now

38mm/30mm(1.5''/1.18'') step shankJZ89/38-TS6C/M22-23-3JZ89/38-TS37C/M25-23-3JZ76/38-TS30C/M25-23-3JZ76/38-TS32C/M22-23-3JZ64/38-TS5C/Z19-23-3JZ64/38-TS40C/M19-23-3JZ64/38-TS41C/M22-23-330mm(1.18'') WSM step shankJZ77/38-WSM/Z17-23-3JZ77/38-WSM/Z19-23-3JZ77/38-WSM/Z22-23-3JZ77/38-WSM/Z25-23-3JZ77/38-WSMX/Z25-23-3JZ77/38-WSMX/Z25-42N-342mm(1.66'') WSM step shankJZ77/42-WSM/M22-23-3JZ77/42-WSM/Z22-23-3JZ77/42-WSM/M25-23-3JZ77/42-WSM/Z25-23-3Surface mining bits, also known as surface mining picks or surface mining teeth, are cutting tools specifically designed for

Contact Now

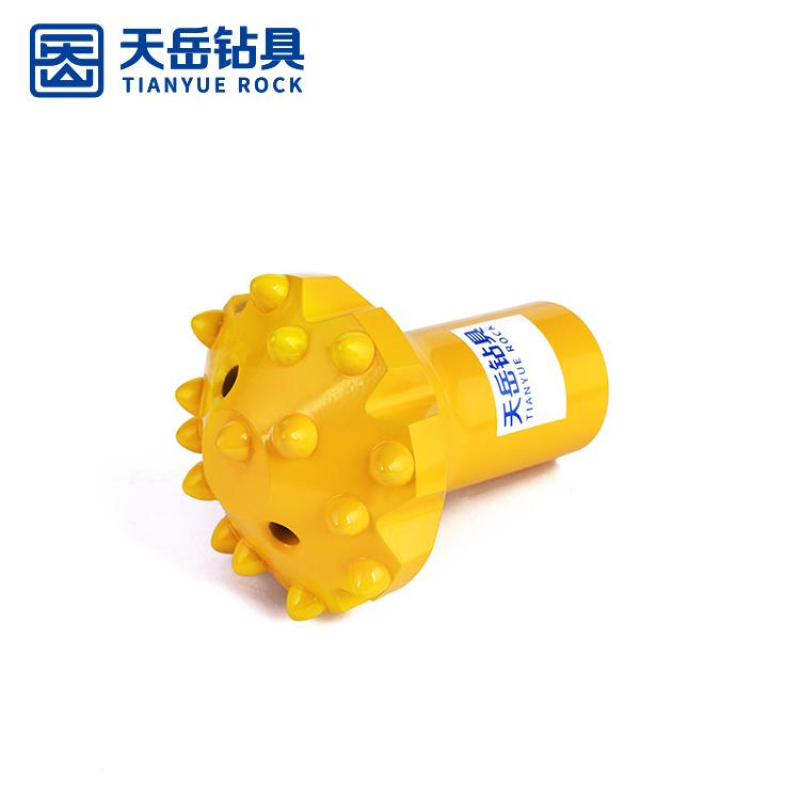

Features:The Top Hammer Reaming Drilling Bit is renowned for its exceptional wear resistance, making it highly effective on medium-hard to hard abrasive rock formations. Its design includes spherical tungsten carbide inserts, which provide a strong defense against carbide fracture. 3.

Contact Now

Use material:Carbide head: High-end tungsten-cobalt alloyWear-resistant layer: Cemented carbide metallurgical composite materialSolder flux: Copper-based solder and fluxTooth body: High-quality 42CrMo alloy steel38mm/30mm(1.50'' /1.18'' ) step shankJZ70/38-U47/M19-42-3JZ80/38-U47/M22-42-3JZ80/38-U47/M25-42-3JZ68/38-U47/M25-42-3JZ75/38-S160/Z22-42-3JZ75/38-S160/Z25-42-338mm(1.5'') shankJZ80/38-U135/M22-42-3JZ80/38-U135/M25-42-3JZ78/38-S150/M25-42-3JZ78/38-S150/Z25-42-3JZ84/38-JMS260/Z25-42-3JZ82/38-JMS260/Z25-42-334mm(1.34'') shankJZ78/34-S100/M22-42-3JZ76/34-S10

Contact Now

Tianyue retrac button bits are made of high-quality steel and cemented carbide as raw materials, so they have a long service life. And the use of retrac bits minimize the loss of impact energy during transmission. In addition, the advanced button fixing technology makes the fixing force uniform and not easy to loose buttons.

Contact Now

Features:Premium designs and high-quality materials are essential for optimal drilling performance. Tianyue is a trusted supplier of premium tungsten carbide insert grade T6 and steel, providing industry-leading strength and penetration rates. With these premium materials, you can expect increased productivity and efficiency. The excellent straightness and hole clean quality of our products ensure precise drilling operations. By choosing Tianyue, you can achieve maximum drilling performance for your rock drills.

Contact Now

Thread Size (T38): As mentioned, T38 refers to the thread size, and it is essential to ensure compatibility with the drilling equipment being used.Material: Reaming drill bits are typically made from high-quality materials such as tungsten carbide or other hard alloys.

Contact Now

Productionprocesses: involving multiple processes, such as steel rolling, forging, normalizing,quenching and tempering,carbide welding,etc.Integral Drill RodBit Diameter24mm~40mmRod DiameterHex19, Hex22Shank Length108mmEffective Length400mm~6400mmIntegral drill steelsLengthBit dia.WeightapproxkgTIANYUE P/NmmfootChisel bit integral Shank 19mm×108mm4001'4"291.35H19-291508-0400-40-25001'8"291.55H19-291508-0500-40-28002'7"282.25H19-281508-0800-40-210003'33/8"282.65H19-281508-1000-40-212003'11"2735H19-271508-1200-40-216005'3"273.95H19-271508-160

Contact Now

Button Configuration:T51 retrac button bits are equipped with hard and durable buttons, typically made of tungsten carbide. These buttons are strategically placed on the face of the bit for efficient rock penetration and breaking.Applications:T51 retrac button bits are suitable for various drilling applications, including blast hole drilling, exploration drilling, and production drilling in medium to hard rock formations.

Contact Now

Material: These drill bits are typically made from durable materials such as tungsten carbide or other hard alloys to withstand the abrasive conditions encountered in drilling through rocks and other tough materials.Cutting Structure: The cutting structure of T45 reaming drill bits is designed to efficiently remove material as the drill bit enlarges previously drilled holes.

Contact Now

Features:Our products are solutions that increase the return on your rig investment by increasing drilling efficiency and reliability. Superior quality and durability with special heat treatment and stress relief for maximum performance and hole cleaning capabilities. Thread button drill bits are made of high quality alloy steel rod and tungsten carbide. Heat treatment makes our drilling tools strong enough to handle your rock drilling needs while minimizing energy loss when drilling rock.

Contact Now

Material and Construction:T51 reaming drill bits are typically constructed from high-strength materials, such as tungsten carbide for the cutting edges. The body of the bit is made from alloy or tool steel to withstand the forces encountered during reaming.Applications:Reaming drill bits in mining are used for various purposes, including blast hole drilling, exploration drilling, and production drilling.

Contact Now

Material and Construction:R32 reaming drill bits are typically constructed from high-strength materials such as tungsten carbide for the cutting edges. The body of the bit is made from alloy or tool steel to withstand the forces encountered during reaming.Applications:Reamer drill bits are used in various industries such as mining, construction, and manufacturing.

Contact Now

Features:Rock drilling tools, including the button bit, have a wide range of applications in different industries. They are heavily used in underground mining operations as well as tunneling and quarrying projects.

Our button bit offers a competitive advantage due to several factors. Firstly, we utilize high-grade tungsten carbide inserts that enhance its performance and longevity. Additionally, our button bit bodies are manufactured from top-quality steel and are processed using state-of-the-art CNC machinery and heat treatment techniques.

Contact Now

Features:Made from top quality steel and tungsten carbide as same as internationally well-known brand.Apply “hot-insertion” processing procedure to insert the buttons as same as internationally well-known brand.Optimized designs improve the drilling speed.Automatic production line ensure the quality stability.Military grade requirements of heat-treatment guarantee durability of the bits.Keywords:Button bit,Thread button bit,Rock drill bit,Tophammer drill bit,Drill bit,Rock bit,Rock dilling tools,Rock dill tool,Rock tools,Tophammer drilling toolsWorking with hydraulic drill rig, Threaded Drilli

Contact Now

Features:The threaded drill bit, equipped with the hydraulic drilling jumbo, is used for crushing rock. It is widely utilized in tunnel construction, large-scale open and underground mines, as well as for large section tunnel advancement in metal mining.Our threaded button bit is manufactured using the highest quality alloy steel bar and tungsten carbide. It undergoes a heat treatment process, ensuring its durability and performance. The threaded button bit comes in various sizes, including R25, R28, R32, R35, R38, T45, T51, ST58, GT60, ST68, and more.

Contact Now

Our tapered button bit was from high quality cemented carbide and produced with heat treatment technology, which connected with tapered drill rod well for air leg or hand-held rock drill machine for drilling holes in gold and coal mining, marble and granite quarries, stone project, tunnel, water conservancy, etc.Drill bitDiameterNo×button diameterFlushing holeWeight approx kgTIANYUE P/NmminchFrontGaugeAngleFrontSide Button bit,Short skirt281 7/641×73×720°110.20 1431-281222-17/37-45-51281 7/641×74×735°110.20 1431-281222-17/47-45-51291 9/641×73×740°110.211431-29

Contact Now

Features:· Made from steel and tungsten carbide as same grade as internationally well-known brand.· Apply “hot-insertion” processing procedure to insert the buttons as same as internationally well-known brand.· Entire CNC processing procedure ensure the quality consistency.· Military grade requirements of heat-treatment guarantee durability.ProductButton BitOther NamesButton drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bitMaterial23

Contact Now

Versatility:Taper drill bits are versatile and can be used for a range of drilling applications, including exploration drilling, blast hole drilling, and rock drilling.Drill bitDiameterNo×button diameterFlushing holeWeight approx kgTIANYUE P/NmminchFrontGaugeAngleFrontSide Button bit,Short skirt321 1/4 1×83×835°110.241431-321122-18/38-45-51321 1/4 2×75×740°110.241431-321122-27/57-45-51331 19/642×74×740°110.251431-331122-27/47-45-51341 11/322×74×740°110.291431-341122-27/47-45-51351 3/8 2×75×735°110.331431-351122-27/57-45-51351 3/8 2×75×835°110.33

Contact Now

An R25 Cross Bit refers to a specific type of rock drill bit designed for percussive drilling methods, particularly in mining and construction applications. Let's break down the key features and information about an R25 Cross Bit:Thread Type and Size:The "R25" designation indicates a specific thread type used in the drilling industry. R25 refers to the thread size and configuration used for connecting the drill bit to the drill string.Cross Bit Design:The term "Cross Bit" implies that the cutting structure on the bit resembles a cross.

Contact Now

Material and Construction:Mining cross bits are usually constructed from high-strength materials such as alloy or tool steel.

Contact Now