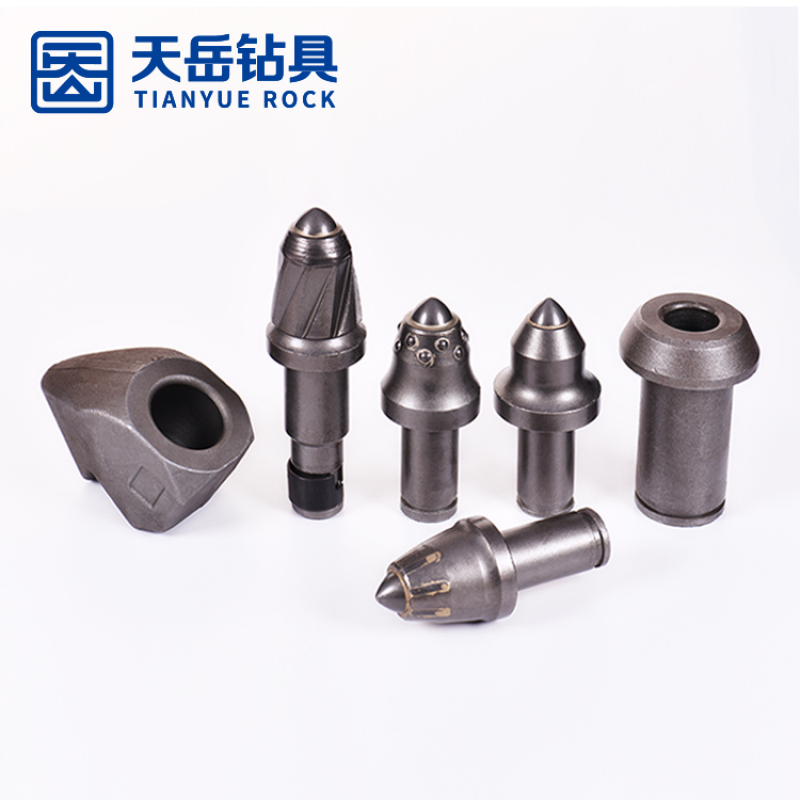

Conical Shape:The conical shape of these picks contributes to their effectiveness in penetrating and cutting through hard materials.Pointed Tip:The pointed tip enhances the penetration capability of the tool, allowing it to break and chip away at the material.Cutting Edges:Conical picks have cutting edges designed to efficiently remove material during excavation. The arrangement of these cutting edges can vary.Material Composition:Conical pick tools are typically made from wear-resistant materials to withstand the abrasiveness of the materials being excavated.

Contact Now

Attachment Mechanism:The conical pick sleeve serves as a connecting element between the conical pick and the drilling equipment. It is designed to securely hold and attach the conical pick to the drill rod or other cutting apparatus.Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDMaterial:Conical pick sleeves are typically made from durable and wear-resistant materials, ensuring longevity and performance in challenging drilling or cutting environments.

Contact Now

Product numberPick length(mm)Length of head(mm)Pick hanldle diameter(mm)PDC insert diameter(mm)Pick head diameter(mm)U8215280301450U8414270301650U8516185301450U92195101351655U9418390351955U9518288352455U17021589432264D4714065302350D12014368301655D13515580381963Advantages of TianYue Mining Bits:* Quick-change connection design for easy replacement* Forging technology provides high strength properties.* Unique body shape designed to maximize efficiency and cuts*Our engineering team can work with your engineering and also make sample products, to make your ideal product.43mm/35mm(1.70'' /

Contact Now

38mm/30mm(1.5''/1.18'') step shankJZ89/38-TS6C/M22-23-3JZ89/38-TS37C/M25-23-3JZ76/38-TS30C/M25-23-3JZ76/38-TS32C/M22-23-3JZ64/38-TS5C/Z19-23-3JZ64/38-TS40C/M19-23-3JZ64/38-TS41C/M22-23-330mm(1.18'') WSM step shankJZ77/38-WSM/Z17-23-3JZ77/38-WSM/Z19-23-3JZ77/38-WSM/Z22-23-3JZ77/38-WSM/Z25-23-3JZ77/38-WSMX/Z25-23-3JZ77/38-WSMX/Z25-42N-342mm(1.66'') WSM step shankJZ77/42-WSM/M22-23-3JZ77/42-WSM/Z22-23-3JZ77/42-WSM/M25-23-3JZ77/42-WSM/Z25-23-3Surface mining bits, also known as surface mining picks or surface mining teeth, are cutting tools specifically designed for

Contact Now

Cutting Structure:Road mining tools have a cutting structure, typically made of carbide or other wear-resistant materials, to effectively mill or cut through asphalt, concrete, or other road surfaces.Variety of Shapes:These tools come in various shapes, including bits, picks, or teeth, depending on the specific application and the type of road milling machine used.20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Material Composition:The cutting tips or inserts on road mining tools are often made from materials such as tungsten carbide for durability and resistance to we

Contact Now

With the experts in geotechnical engineering and metal material industry as the core and the advanced production process as its basis,the company focus on the studying of tools for geotechnical engineering and tries its best to pursuit perfect quality and product innovation to meet our clients's requirements.Road milling tools are essential components used in the road construction and maintenance industry. They are used to remove old asphalt or concrete surfaces, prepare surfaces for new pavement, and perform various other tasks in road rehabilitation and construction.

Contact Now

Excavators:Excavators are heavy machinery used to remove overburden (the layers of soil, rock, and other materials covering the mineral deposit) in surface mining. They have a bucket attached to a boom, which is used to scoop and transport materials.Draglines:Draglines are large machines equipped with a system of ropes and buckets. They are used to remove overburden and expose the mineral deposit.

Contact Now

Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDCoal cutter teeth sleeves are components used in coal cutting machinery to protect and enhance the performance of the cutting tools, commonly known as coal cutter teeth or picks. These sleeves play a crucial role in the coal mining industry, where specialized equipment is used to extract coal from underground or open-pit mines.

Contact Now

1.FunctionThe primary function of surface mining bits is to:Cut and Fragment Rock: Efficiently break and fragment rock or ore for easier extraction and processing.Enhance Drilling Efficiency: Increase the efficiency of drilling operations by providing reliable and consistent cutting performance.Reduce Wear and Tear: Minimize wear and tear on mining equipment by using durable, wear-resistant materials.2.

Contact Now

Beyond Expectations – Shank Adapter COP BBCIn the contemporary realms of blasting and mining, the Shank Adapter COP BBC stands out as the favored selection among industry experts owing to its exceptional performance and dependability.

Contact Now

20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Road milling tools, also known as road milling bits or asphalt milling cutters, are cutting tools used in road milling machines or cold planers. These tools are essential in the process of removing and reclaiming the existing pavement surface on roads and highways. Road milling is a common method for resurfacing, rehabilitation, or upgrading road surfaces. Here are key features and information about road milling tools:Design:Road milling tools are designed to break and remove the asphalt or concrete surface of roads.

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious fashions catering to your desires:introducing our mining manual tubes, to be had in a number of models in conjunction with r32, t38, t45, t51, and t60.

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious models catering on your wishes:introducing our mining manual tubes, available in a range of fashions along with r32, t38, t45, t51, and t60.

Contact Now

Beyond Expectations – Shank Adapter COP BBCIn the modern fields of blasting and mining, the Shank Adapter COP BBC has become the preferred choice of industry professionals due to its outstanding performance and reliability.

Contact Now

Material and Construction:Mining drifter rods are typically constructed from high-strength alloy or tool steel to withstand the intense mechanical forces and vibrations encountered during rock drilling in mining environments.

Contact Now

Mining and Quarrying:Tapered drill rods with an 11-degree angle are commonly used in mining and quarrying operations.

Contact Now

Unleash Mining Potential with Speed Drill Rods: Elevating Efficiency and PrecisionIntroduction to Mining Speed Drill Rods:Introducing the Mining Speed Drill Rod, a groundbreaking solution designed to revolutionize the world of mining exploration.

Contact Now

Unleashing Power Below Ground – Mining Extension Drill RodInside the challenging world of mining, precision and sturdiness are paramount. introducing our present day product – the mining extension drill rod. engineered for the pains of the mining enterprise, this tool is your key to unlocking new depths and enhancing drilling efficiency.

Contact Now

Unleashing Power Below Ground – Mining Extension Drill RodWithin the tough international of mining, precision and durability are paramount. introducing our present day product – the mining extension drill rod. engineered for the rigors of the mining enterprise, this tool is your key to unlocking new depths and enhancing drilling efficiency.

Contact Now

Unleashing Power Below Ground – Mining Extension Drill RodNavigating the demanding realm of mining demands a blend of precision and durability. Allow us to present our state-of-the-art solution – the Mining Extension Drill Rod. Purpose-built for the challenges inherent in the mining industry, this tool serves as your gateway to delving into uncharted depths and elevating drilling efficiency.

Contact Now

Unleashing Power Below Ground – Mining Extension Drill RodR32 Extension Rods are a crucial component in rock drilling operations, offering durability and precision in challenging conditions.

Contact Now

Unveiling the Mining Drifter Drill Rod: A Revolution in Mining EfficiencyPrecision Unleashed:Welcome to a new era of precision drilling with the Mining Drifter Drill Rod. Engineered with cutting-edge technology, this tool redefines accuracy in mining exploration.

Contact Now

Unlocking Depths: The Versatility of T38 Extension Rod in Mining OperationsExtension drill rods are components used in drilling operations to extend the reach of the drill string. They are commonly employed in mining, construction, geotechnical exploration, and other applications where deep drilling is required.

Contact Now

Compatibility:It is important to ensure that mining reaming drill bits are compatible with the drilling equipment being used. Checking screw types and other specifications will help ensure safe and efficient drilling operations.Maintenance:Regular inspection and maintenance of mining reaming drill bits are essential for optimal performance.

Contact Now