Standard coupling sleeve, also known as semi bridge coupling sleeve, has a section of the bridge without a thread in the middle. The threaded part of the drill pipe cannot be screwed through the bridge part of the coupling, and the end of the thread can closely adhere to the casing bridge zone. Standard coupling sleeve is particularly suitable for high-torque drilling rigs. Most rope thread (R thread) and trapezoidal thread (T thread) coupling sleeves are with half-bridge type.

Contact Now

Coupling Sleeve is a high-performance coupling sleeve designed for mechanical systems, dedicated to providing outstanding durability and reliability.

Contact Now

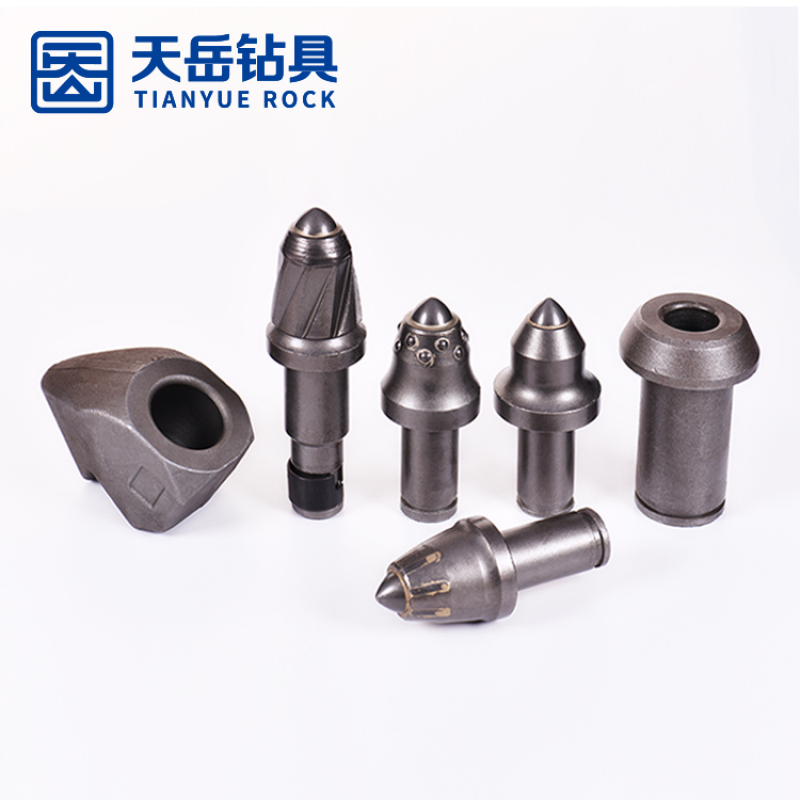

Attachment Mechanism:The conical pick sleeve serves as a connecting element between the conical pick and the drilling equipment. It is designed to securely hold and attach the conical pick to the drill rod or other cutting apparatus.Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDMaterial:Conical pick sleeves are typically made from durable and wear-resistant materials, ensuring longevity and performance in challenging drilling or cutting environments.

Contact Now

Unleash Precision and Power with R38 Coupling SleevesElevate your drilling operations to new heights with our state-of-the-art R38 Coupling Sleeves.

Contact Now

Elevate Your Drilling Game with R35 Coupling Sleeves: Unrivaled Precision and DurabilityUnleash the power of precision and durability in your drilling endeavors with our top-of-the-line R35 Coupling Sleeves.

Contact Now

R25 Coupling Sleeves: Seamless Connections for Efficient DrillingIn the realm of drilling excellence, the R25 Coupling Sleeves stand as a testament to precision engineering and unwavering reliability.

Contact Now

Master T45 Coupling Sleeves for Precision Drilling and Outstanding PerformanceIn the realm of drilling, T45 Coupling Sleeves achieve exceptional precision and reliability, injecting robust power into your projects.

Contact Now

Drill Coupling Sleeves:In drilling applications, coupling sleeves are used to connect and join drill rods.

Contact Now

Optimize Your Drilling Efficiency with R32 Coupling SleevesUnlock unparalleled performance in your drilling operations with our cutting-edge R32 Coupling Sleeves.

Contact Now

Coupling sleeves are essential components in rock drilling, serving to connect various segments of the drill string, such as shank adapters, drill rods, and drill bits. They ensure continuity in the drill string and facilitate the efficient transfer of rotational and percussive forces. Here's a detailed overview of coupling sleeves and the types available:Coupling Sleeves Overview1. DefinitionCoupling sleeves are cylindrical components with internal threads used to join two sections of a drill string, such as a shank adapter to a drill rod or two drill rods.

Contact Now

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's ChoiceUnlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters.

Contact Now

In addition to the T45 button bit for hard rock drilling mentioned earlier, we also offer a wide range of top hammer hard rock mining tools, including drilling bits, drill rods, shank adapters for drills, and coupling sleeves.

We take pride in providing the best drill bits for hard rock applications.Our selection includes various hard rock drill bits with different specifications to meet your specific needs. Thread options available include R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, among others.

Contact Now

Application:The R28 Speed Rod is used in a variety of drilling operations including exploration drilling, rock drilling, tunneling and other applications.

Contact Now

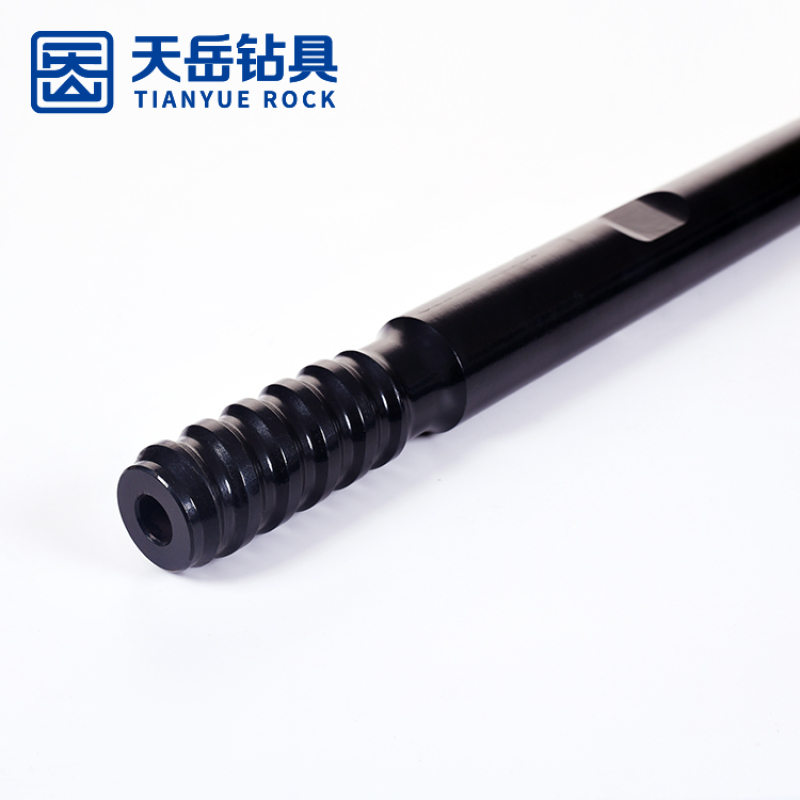

Material and Construction:Mining drifter rods are typically constructed from high-strength alloy or tool steel to withstand the intense mechanical forces and vibrations encountered during rock drilling in mining environments.

Contact Now

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body.

Contact Now

Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDCoal cutter teeth sleeves are components used in coal cutting machinery to protect and enhance the performance of the cutting tools, commonly known as coal cutter teeth or picks. These sleeves play a crucial role in the coal mining industry, where specialized equipment is used to extract coal from underground or open-pit mines.

Contact Now

Application:R25 Speed Rods are used in drilling operations, particularly in tasks such as exploration drilling, rock drilling, and tunneling.

Contact Now

Construction:Drifter rods are typically made of high-quality alloy or tool steel to withstand the forces and stresses encountered during drilling.

Contact Now

22mm(0.87'') step shankJZ44/22-C858/P25-23-2JZ44/22-C87/P25-23-2JZ46/22-C387/P16-23-2JZ49/22-C87/P16-23-2JZ43/22-K1LW/C16Y-23-2JZ45/22-K1LW/C16-23-2Grader blades are components used in grader machines, which are heavy equipment vehicles widely used in construction, road maintenance, and civil engineering projects. Graders, also known as motor graders or road graders, are equipped with a long blade that is adjustable and positioned between the front and rear axles. The grader blade plays a crucial role in leveling and shaping surfaces, such as roads and construction sites.

Contact Now

Material:Mining speed rods are typically constructed from high-strength steel or other durable materials.

Contact Now

Material:T38 Speed Rods are typically made from high-strength steel to withstand the stresses and forces encountered during drilling operations.Application:T38 Speed Rods are used in various drilling applications, including exploration drilling, rock drilling, tunneling, and other tasks.

Contact Now

Material:T45 MF rods are made of high-strength steel to withstand the stresses and forces typically encountered during drilling operations.Application:T45 MF rods are used in a variety of drilling applications, including exploration drilling, rock drilling, tunneling and other operations.

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious fashions catering to your desires:introducing our mining manual tubes, to be had in a number of models in conjunction with r32, t38, t45, t51, and t60.

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious models catering on your wishes:introducing our mining manual tubes, available in a range of fashions along with r32, t38, t45, t51, and t60.

Contact Now