Integral drill rod is a type of drilling tool that is commonly used in mining and construction industries. It is designed to be used with rock drills for drilling blast holes, production drilling, and anchoring. Integral drill rods are made from high-quality alloy steel and feature an integrated and hardened drill bit at one end.

These drill rods are known for their durability, high drilling efficiency, and ability to withstand heavy-duty drilling tasks in challenging rock formations.

Contact Now

Material and Construction:T51 reaming drill bits are typically constructed from high-strength materials, such as tungsten carbide for the cutting edges. The body of the bit is made from alloy or tool steel to withstand the forces encountered during reaming.Applications:Reaming drill bits in mining are used for various purposes, including blast hole drilling, exploration drilling, and production drilling.

Contact Now

Material and Construction:R32 reaming drill bits are typically constructed from high-strength materials such as tungsten carbide for the cutting edges. The body of the bit is made from alloy or tool steel to withstand the forces encountered during reaming.Applications:Reamer drill bits are used in various industries such as mining, construction, and manufacturing.

Contact Now

Diameter:The "22mm" specification refers to the diameter of the integral drill steel. In this case, it indicates that the diameter of the drill steel is 22 millimeters.Material:Integral drill steels are typically made from high-strength steel to withstand the mechanical stresses and abrasion encountered during drilling operations. The choice of material is crucial for the durability and performance of the drill steel.Integral Design:Being integral means that the drill steel is manufactured as a single unit with the drill bit.

Contact Now

Compatibility:It is important to ensure that mining reaming drill bits are compatible with the drilling equipment being used. Checking screw types and other specifications will help ensure safe and efficient drilling operations.Maintenance:Regular inspection and maintenance of mining reaming drill bits are essential for optimal performance.

Contact Now

Compatibility with Tapered Drill Rods:Tapered drill bits are typically used in conjunction with tapered drill rods.

Contact Now

Thread Type:The "R" in R28 stands for "round," indicating that the thread type is circular. The "28" denotes the diameter of the thread in millimeters. R28 is a standardized thread type used in the drilling industry to ensure compatibility with various drilling equipment.Reaming Operation:Reaming drill bits are specifically designed for the reaming process, where the drill bit is used to enlarge an existing hole.

Contact Now

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body.

Contact Now

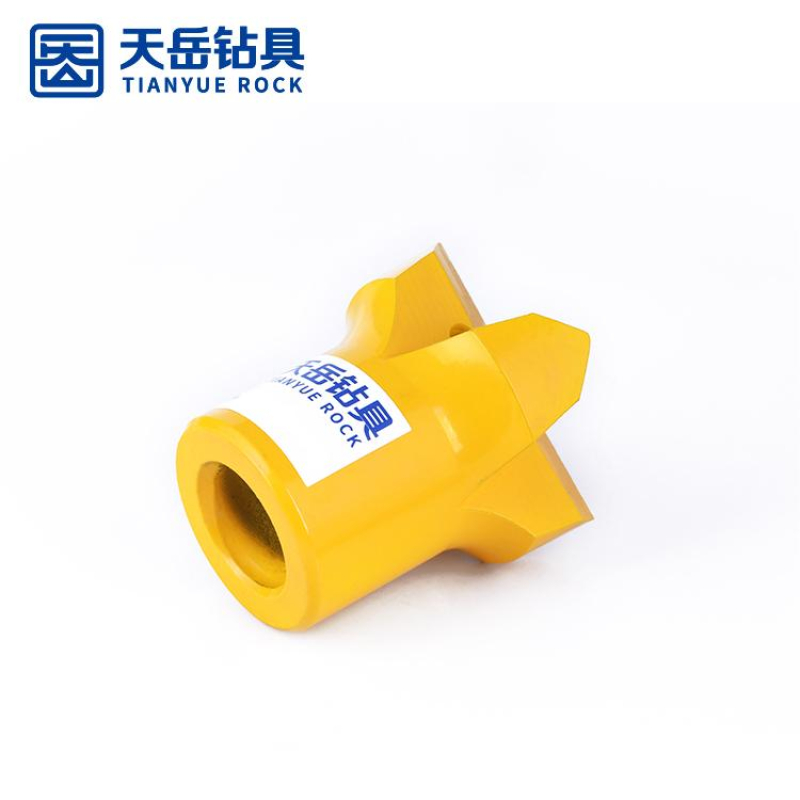

Material and Construction:Mining cross bits are usually constructed from high-strength materials such as alloy or tool steel.

Contact Now

Thread Size (T38): As mentioned, T38 refers to the thread size, and it is essential to ensure compatibility with the drilling equipment being used.Material: Reaming drill bits are typically made from high-quality materials such as tungsten carbide or other hard alloys.

Contact Now

Material and Construction:R32 cross bits are usually constructed from high-strength materials, such as alloy or tool steel, to withstand the mechanical stresses and vibrations associated with rock drilling.Applications:R32 cross bits are suitable for various drilling applications, including blast hole drilling, exploration drilling, and production drilling in softer to medium-hard rock formations.

Contact Now

Material: These drill bits are typically made from durable materials such as tungsten carbide or other hard alloys to withstand the abrasive conditions encountered in drilling through rocks and other tough materials.Cutting Structure: The cutting structure of T45 reaming drill bits is designed to efficiently remove material as the drill bit enlarges previously drilled holes.

Contact Now

Reaming bits play a crucial role in the world of rock drilling machinery, specifically in the field of engineering and construction equipment. These bits are essential components that aid in the drilling and excavation processes, ensuring accuracy, stability, and productivity.Rock drilling machinery is commonly used in various applications, such as mining, tunneling, and construction projects. The success of these operations relies heavily on the quality and performance of the reaming bits used.

Contact Now

Sizes and Variations:Rock tools come in various sizes to accommodate different drilling requirements. The selection of the appropriate size depends on factors such as the desired hole diameter and the specific geological conditions of the drilling site.Applications:Rock tools for furnace cross bits may find applications in drilling holes for various purposes related to furnace construction, maintenance, or specific industrial processes.

Contact Now

Our company drill rods are manufactured from premium, high-strength, alloy steel and are available in either hexagonal and round configurations. Sandvik rods are developed and designed to give you straighter holes with less deviation and longer service life.Factory showCompany ProfileShandong Yanggu Tianyue Drilling Tools Co., Ltd.

Contact Now

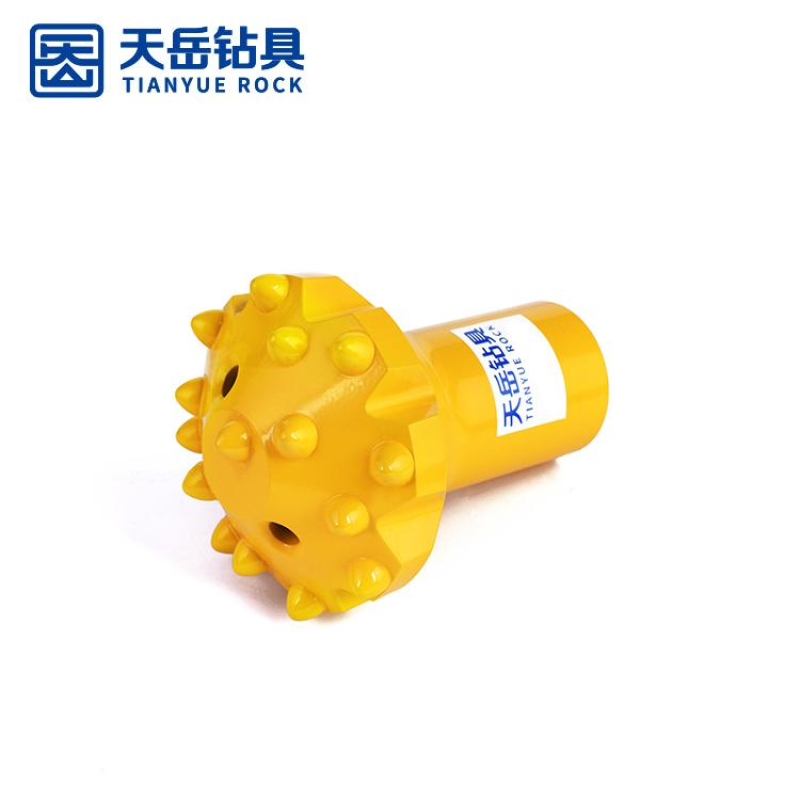

Tianyue retrac button bits are made of high-quality steel and cemented carbide as raw materials, so they have a long service life. And the use of retrac bits minimize the loss of impact energy during transmission. In addition, the advanced button fixing technology makes the fixing force uniform and not easy to loose buttons.

Contact Now

It is common practice to bump up the drive end of drifting drill steel for added strength at the rock drill end to accommodate larger diameter and shank adapters. Drill steel of rock drilling tools is available in many standard lengths to match the drill feeds on a multitude of available drifting jumbos.

Contact Now

Versatility:Taper drill bits are versatile and can be used for a range of drilling applications, including exploration drilling, blast hole drilling, and rock drilling.Drill bitDiameterNo×button diameterFlushing holeWeight approx kgTIANYUE P/NmminchFrontGaugeAngleFrontSide Button bit,Short skirt321 1/4 1×83×835°110.241431-321122-18/38-45-51321 1/4 2×75×740°110.241431-321122-27/57-45-51331 19/642×74×740°110.251431-331122-27/47-45-51341 11/322×74×740°110.291431-341122-27/47-45-51351 3/8 2×75×735°110.331431-351122-27/57-45-51351 3/8 2×75×835°110.33

Contact Now

In addition to the T45 button bit for hard rock drilling mentioned earlier, we also offer a wide range of top hammer hard rock mining tools, including drilling bits, drill rods, shank adapters for drills, and coupling sleeves.

We take pride in providing the best drill bits for hard rock applications.Our selection includes various hard rock drill bits with different specifications to meet your specific needs. Thread options available include R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, among others.

Contact Now

Applications:Retrac button bits find applications in various drilling operations, including mining, quarrying, tunneling, and construction. They are suitable for drilling blast holes, anchor holes, exploration drill holes, and other rock drilling tasks.Face Design:The face design of retrac button bits may include options such as flat face, drop center, concave, or convex designs. The choice of face design depends on specific drilling requirements and the type of rock being encountered.Sizes and Variations:Retrac button bits come in various sizes to accommodate different drilling requirements.

Contact Now

Top Hammer Reaming Drilling Bit is well known for its high wear resistance on medium-hard to hard abrasive rock formations.

Contact Now

Features:Thread drill bits are crafted using premium alloy steel bars and tungsten carbides, ensuring their exceptional quality and durability.

By undergoing a meticulous heat treatment process, our drilling tools are capable of withstanding the most rigorous rock drilling requirements, while also minimizing energy loss during the drilling process.

Furthermore, we offer the flexibility to create customized thread button drill bits that cater to specific drilling applications.

Contact Now

Features:· Made from steel and tungsten carbide as same grade as internationally well-known brand.· Apply “hot-insertion” processing procedure to insert the buttons as same as internationally well-known brand.· Entire CNC processing procedure ensure the quality consistency.· Military grade requirements of heat-treatment guarantee durability.ProductButton BitOther NamesButton drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bitMaterial23

Contact Now

1.FunctionThe primary function of surface mining bits is to:Cut and Fragment Rock: Efficiently break and fragment rock or ore for easier extraction and processing.Enhance Drilling Efficiency: Increase the efficiency of drilling operations by providing reliable and consistent cutting performance.Reduce Wear and Tear: Minimize wear and tear on mining equipment by using durable, wear-resistant materials.2.

Contact Now