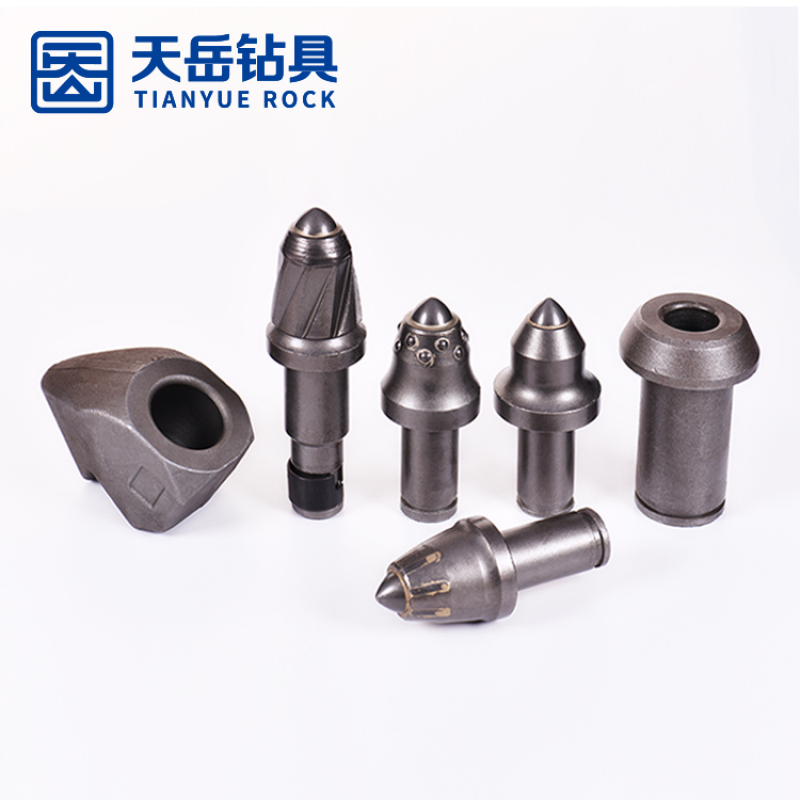

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body.

Contact Now

Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDCoal cutter teeth sleeves are components used in coal cutting machinery to protect and enhance the performance of the cutting tools, commonly known as coal cutter teeth or picks. These sleeves play a crucial role in the coal mining industry, where specialized equipment is used to extract coal from underground or open-pit mines.

Contact Now

With an expert group in the field of geotechnical engineering and metal materials as the core, and based on advanced production technology, the company focuses on the exploration of the field of geotechnical engineering tools, and constantly pursues quality perfection and product innovation to satisfy users in geotechnical engineering.

Contact Now

Use material:Carbide head: High-end tungsten-cobalt alloyWear-resistant layer: Cemented carbide metallurgical composite materialSolder flux: Copper-based solder and fluxTooth body: High-quality 42CrMo alloy steel38mm/30mm(1.50'' /1.18'' ) step shankJZ70/38-U47/M19-42-3JZ80/38-U47/M22-42-3JZ80/38-U47/M25-42-3JZ68/38-U47/M25-42-3JZ75/38-S160/Z22-42-3JZ75/38-S160/Z25-42-338mm(1.5'') shankJZ80/38-U135/M22-42-3JZ80/38-U135/M25-42-3JZ78/38-S150/M25-42-3JZ78/38-S150/Z25-42-3JZ84/38-JMS260/Z25-42-3JZ82/38-JMS260/Z25-42-334mm(1.34'') shankJZ78/34-S100/M22-42-3JZ76/34-S10

Contact Now

20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Road milling tools, also known as road milling bits or asphalt milling cutters, are cutting tools used in road milling machines or cold planers. These tools are essential in the process of removing and reclaiming the existing pavement surface on roads and highways. Road milling is a common method for resurfacing, rehabilitation, or upgrading road surfaces. Here are key features and information about road milling tools:Design:Road milling tools are designed to break and remove the asphalt or concrete surface of roads.

Contact Now

Product numberPick length(mm)Length of head(mm)Pick hanldle diameter(mm)PDC insert diameter(mm)Pick head diameter(mm)U8215280301450U8414270301650U8516185301450U92195101351655U9418390351955U9518288352455U17021589432264D4714065302350D12014368301655D13515580381963Advantages of TianYue Mining Bits:* Quick-change connection design for easy replacement* Forging technology provides high strength properties.* Unique body shape designed to maximize efficiency and cuts*Our engineering team can work with your engineering and also make sample products, to make your ideal product.43mm/35mm(1.70'' /

Contact Now

Cutting Structure:Road mining tools have a cutting structure, typically made of carbide or other wear-resistant materials, to effectively mill or cut through asphalt, concrete, or other road surfaces.Variety of Shapes:These tools come in various shapes, including bits, picks, or teeth, depending on the specific application and the type of road milling machine used.20mm(0.76'') step shankDA35DA519DA2022DM1019DM2022DM622DM1922DC35Material Composition:The cutting tips or inserts on road mining tools are often made from materials such as tungsten carbide for durability and resistance to we

Contact Now

R25 Coupling Sleeves: Seamless Connections for Efficient DrillingIn the realm of drilling excellence, the R25 Coupling Sleeves stand as a testament to precision engineering and unwavering reliability.

Contact Now

With the experts in geotechnical engineering and metal material industry as the core and the advanced production process as its basis,the company focus on the studying of tools for geotechnical engineering and tries its best to pursuit perfect quality and product innovation to meet our clients's requirements.Road milling tools are essential components used in the road construction and maintenance industry. They are used to remove old asphalt or concrete surfaces, prepare surfaces for new pavement, and perform various other tasks in road rehabilitation and construction.

Contact Now

Unleash Precision and Power with the T45 Guide TubeElevate your drilling operations to new heights with the T45 Guide Tube – a pinnacle of engineering excellence tailored for top hammer drilling.

Contact Now

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's ChoiceUnlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters.

Contact Now

38mm/30mm(1.5''/1.18'') step shankJZ89/38-TS6C/M22-23-3JZ89/38-TS37C/M25-23-3JZ76/38-TS30C/M25-23-3JZ76/38-TS32C/M22-23-3JZ64/38-TS5C/Z19-23-3JZ64/38-TS40C/M19-23-3JZ64/38-TS41C/M22-23-330mm(1.18'') WSM step shankJZ77/38-WSM/Z17-23-3JZ77/38-WSM/Z19-23-3JZ77/38-WSM/Z22-23-3JZ77/38-WSM/Z25-23-3JZ77/38-WSMX/Z25-23-3JZ77/38-WSMX/Z25-42N-342mm(1.66'') WSM step shankJZ77/42-WSM/M22-23-3JZ77/42-WSM/Z22-23-3JZ77/42-WSM/M25-23-3JZ77/42-WSM/Z25-23-3Surface mining bits, also known as surface mining picks or surface mining teeth, are cutting tools specifically designed for

Contact Now

Conical Shape:The conical shape of these picks contributes to their effectiveness in penetrating and cutting through hard materials.Pointed Tip:The pointed tip enhances the penetration capability of the tool, allowing it to break and chip away at the material.Cutting Edges:Conical picks have cutting edges designed to efficiently remove material during excavation. The arrangement of these cutting edges can vary.Material Composition:Conical pick tools are typically made from wear-resistant materials to withstand the abrasiveness of the materials being excavated.

Contact Now

22mm(0.87'') step shankJZ44/22-C858/P25-23-2JZ44/22-C87/P25-23-2JZ46/22-C387/P16-23-2JZ49/22-C87/P16-23-2JZ43/22-K1LW/C16Y-23-2JZ45/22-K1LW/C16-23-2Grader blades are components used in grader machines, which are heavy equipment vehicles widely used in construction, road maintenance, and civil engineering projects. Graders, also known as motor graders or road graders, are equipped with a long blade that is adjustable and positioned between the front and rear axles. The grader blade plays a crucial role in leveling and shaping surfaces, such as roads and construction sites.

Contact Now

Attachment Mechanism:The conical pick sleeve serves as a connecting element between the conical pick and the drilling equipment. It is designed to securely hold and attach the conical pick to the drill rod or other cutting apparatus.Blocks and SleevesU80K177SU90K225RU170K225SK225SK177SU43XHDMaterial:Conical pick sleeves are typically made from durable and wear-resistant materials, ensuring longevity and performance in challenging drilling or cutting environments.

Contact Now

Optimize Your Drilling Efficiency with R32 Coupling SleevesUnlock unparalleled performance in your drilling operations with our cutting-edge R32 Coupling Sleeves.

Contact Now

In the world of manufacturing and processing machinery, specifically in the field of engineering and construction machinery, rock drilling plays a crucial role. When it comes to efficient and effective rock drilling, crusher pick tools are essential equipment that cannot be overlooked. This article explores the significance of crusher pick tools and their contribution to the success of the construction industry.Unveiling Crusher Pick Tools:Crusher pick tools are specially designed tools used in rock drilling applications.

Contact Now

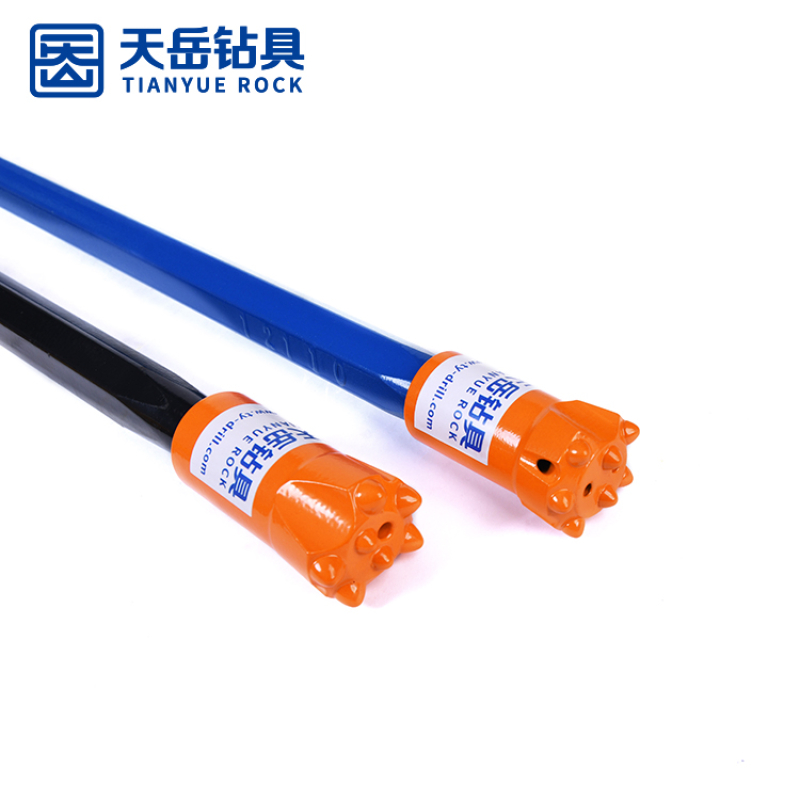

The Retrac Bits are widely applicable to mining industry, tunneling and underground engineering, open pit, construction drill,blast industry, civil engineering operations,road, gas line, pipe and trench projects,quarry work, rock anchoring and ground stabilization projects, water well industry, etc,Retrac Button BitDiameterNo×button diameterFlushing holeWeightapprox kgTIANYUE P/NmminchFrontGaugeAngleFrontSideSpherical buttons702 3/44 X 118 X 1140°2-2.51531-70T45-411/811-45-31702 3/43 X 11, 1 X 96 X 1135°3-2.51533-70T45-411/611-45-31702 3/44 X 10, 1 X 108 X 1135°4-2.51632-70T45-510/811-45-31763

Contact Now

Reaming bits play a crucial role in the world of rock drilling machinery, specifically in the field of engineering and construction equipment. These bits are essential components that aid in the drilling and excavation processes, ensuring accuracy, stability, and productivity.Rock drilling machinery is commonly used in various applications, such as mining, tunneling, and construction projects. The success of these operations relies heavily on the quality and performance of the reaming bits used.

Contact Now

1.FunctionThe primary function of surface mining bits is to:Cut and Fragment Rock: Efficiently break and fragment rock or ore for easier extraction and processing.Enhance Drilling Efficiency: Increase the efficiency of drilling operations by providing reliable and consistent cutting performance.Reduce Wear and Tear: Minimize wear and tear on mining equipment by using durable, wear-resistant materials.2.

Contact Now

Factors to Consider When Choosing Button Bits for Rock CuttingWhen selecting button bits for rock cutting, several key factors should be taken into consideration. These factors include:- Rock Formation: Understanding the geological composition of the rock formation is crucial for choosing the most suitable button bits.

Contact Now

Unveiling the Mining Drifter Drill Rod: A Revolution in Mining EfficiencyPrecision Unleashed:Welcome to a new era of precision drilling with the Mining Drifter Drill Rod. Engineered with cutting-edge technology, this tool redefines accuracy in mining exploration.

Contact Now

Thread Type:The "ST" in ST58 typically refers to a specific thread type, but it's important to note that variations in thread standards may exist. The "58" denotes the diameter of the thread in millimeters. The thread type is crucial for compatibility with various drilling equipment, ensuring a secure and efficient connection.Retrac Design:The retrac design is a distinctive feature of these bits. The cutting buttons on the bit are retractable, allowing them to adapt to changing rock hardness.

Contact Now

A retrac button bit is a type of drill bit designed for rock drilling applications, especially in challenging and abrasive geological conditions. The term "retrac" refers to a specific design feature where the cutting buttons on the bit are retractable, meaning they can move inward into the bit body.

Contact Now