Beyond Expectations – Shank Adapter COP BBCIn the modern fields of blasting and mining, the Shank Adapter COP BBC has become the preferred choice of industry professionals due to its outstanding performance and reliability.

Contact Now

Beyond Expectations – Shank Adapter COP BBCIn the contemporary realms of blasting and mining, the Shank Adapter COP BBC stands out as the favored selection among industry experts owing to its exceptional performance and dependability.

Contact Now

Introducing the Shank Adapter HL RD HLX, an innovative solution at the forefront of rock drilling technology.

Contact Now

Shank Adapter PR YH is an innovative product designed specifically for the industrial sector. It not only breaks through the limitations of traditional tools but also stands out for its outstanding performance and reliability, making it an indispensable choice in modern workplaces.

Contact Now

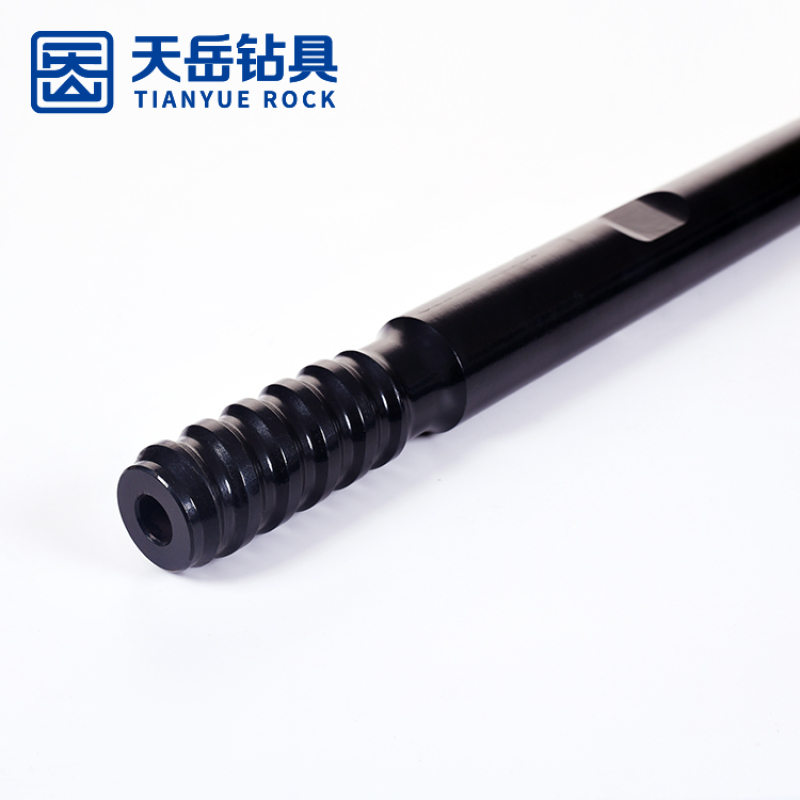

The specification and hardness of top hammer shank adaptor have a great influence on the rock drilling speed and the life of the rock drill. The hardness of the top hammer shank adaptors for drill should be appropriate, the service life is short if the rock drill shank is too soft, the piston is vulnerable to damage if the drill shank adapter is too hard.

Contact Now

Unrivaled PerformanceShank Adapter HD PD stands at the forefront of rock drilling technology, offering unparalleled performance in challenging environments.

Contact Now

Exceptional Design and Efficient PerformanceShank Adapter HC HBM stands out as a premier choice in rock drilling tools, delivering exceptional solutions for challenging rock formations with its exquisite design and efficient performance.

Contact Now

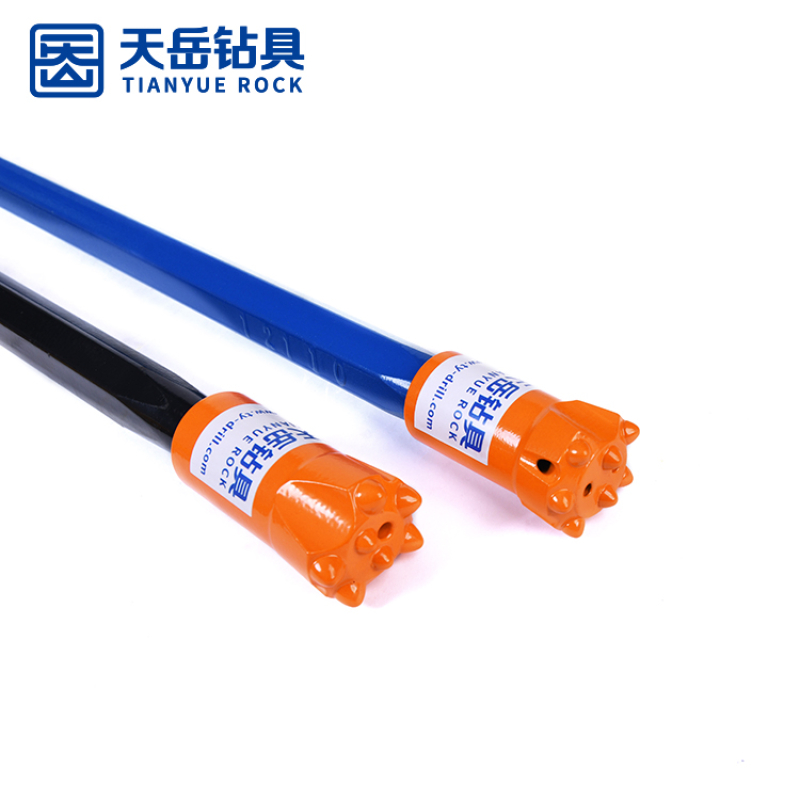

Shank rods are essential components in the drilling industry, playing a crucial role in the efficiency and effectiveness of drilling operations. By choosing high-quality shank rods that are compatible with the specific drilling equipment and applications, professionals can ensure optimal performance, reduced downtime, and extended tool life.

Contact Now

Coupling sleeves are essential components in rock drilling, serving to connect various segments of the drill string, such as shank adapters, drill rods, and drill bits. They ensure continuity in the drill string and facilitate the efficient transfer of rotational and percussive forces. Here's a detailed overview of coupling sleeves and the types available:Coupling Sleeves Overview1. DefinitionCoupling sleeves are cylindrical components with internal threads used to join two sections of a drill string, such as a shank adapter to a drill rod or two drill rods.

Contact Now

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's ChoiceUnlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters.

Contact Now

It is common practice to bump up the drive end of drifting drill steel for added strength at the rock drill end to accommodate larger diameter and shank adapters. Drill steel of rock drilling tools is available in many standard lengths to match the drill feeds on a multitude of available drifting jumbos.

Contact Now

Productionprocesses: involving multiple processes, such as steel rolling, forging, normalizing,quenching and tempering,carbide welding,etc.Integral Drill RodBit Diameter24mm~40mmRod DiameterHex19, Hex22Shank Length108mmEffective Length400mm~6400mmIntegral drill steelsLengthBit dia.WeightapproxkgTIANYUE P/NmmfootChisel bit integral Shank 19mm×108mm4001'4"291.35H19-291508-0400-40-25001'8"291.55H19-291508-0500-40-28002'7"282.25H19-281508-0800-40-210003'33/8"282.65H19-281508-1000-40-212003'11"2735H19-271508-1200-40-216005'3"273.95H19-271508-160

Contact Now

In addition to the T45 button bit for hard rock drilling mentioned earlier, we also offer a wide range of top hammer hard rock mining tools, including drilling bits, drill rods, shank adapters for drills, and coupling sleeves.

We take pride in providing the best drill bits for hard rock applications.Our selection includes various hard rock drill bits with different specifications to meet your specific needs. Thread options available include R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, among others.

Contact Now

As an MF Rod manufacturer, we have two MF rod factories in China. Our MF drill rods are made of high-quality alloy steel and advanced thread manufacturing technology, and have excellent performance in wear resistance and flexibility.

Contact Now

Material:T45 MF rods are made of high-strength steel to withstand the stresses and forces typically encountered during drilling operations.Application:T45 MF rods are used in a variety of drilling applications, including exploration drilling, rock drilling, tunneling and other operations.

Contact Now

Material:T38 Speed Rods are typically made from high-strength steel to withstand the stresses and forces encountered during drilling operations.Application:T38 Speed Rods are used in various drilling applications, including exploration drilling, rock drilling, tunneling, and other tasks.

Contact Now

The R38 Extension Rod 1220mm 1830mm Drill Rod is compatible with various drilling machines, making it a versatile choice for different applications. Whether you are working on construction projects, mining operations, or geotechnical investigations, this drill rod will meet your requirements with ease.

Additionally, the R38 Extension Rod features a convenient and easy-to-use design.

Contact Now

Unleash Mining Potential with Speed Drill Rods: Elevating Efficiency and PrecisionIntroduction to Mining Speed Drill Rods:Introducing the Mining Speed Drill Rod, a groundbreaking solution designed to revolutionize the world of mining exploration.

Contact Now

Our tapered button bit was from high quality cemented carbide and produced with heat treatment technology, which connected with tapered drill rod well for air leg or hand-held rock drill machine for drilling holes in gold and coal mining, marble and granite quarries, stone project, tunnel, water conservancy, etc.Drill bitDiameterNo×button diameterFlushing holeWeight approx kgTIANYUE P/NmminchFrontGaugeAngleFrontSide Button bit,Short skirt281 7/641×73×720°110.20 1431-281222-17/37-45-51281 7/641×74×735°110.20 1431-281222-17/47-45-51291 9/641×73×740°110.211431-29

Contact Now

In top hammer threaded drilling tools, standard threaded button bit is the most widely used drill bit, which can be applied to all rock conditions.

Contact Now

Features:Thread drill bits are crafted using premium alloy steel bars and tungsten carbides, ensuring their exceptional quality and durability.

By undergoing a meticulous heat treatment process, our drilling tools are capable of withstanding the most rigorous rock drilling requirements, while also minimizing energy loss during the drilling process.

Furthermore, we offer the flexibility to create customized thread button drill bits that cater to specific drilling applications.

Contact Now

Factors to Consider When Choosing Button Bits for Rock CuttingWhen selecting button bits for rock cutting, several key factors should be taken into consideration. These factors include:- Rock Formation: Understanding the geological composition of the rock formation is crucial for choosing the most suitable button bits.

Contact Now

A retrac button bit is a type of drill bit designed for rock drilling applications, especially in challenging and abrasive geological conditions. The term "retrac" refers to a specific design feature where the cutting buttons on the bit are retractable, meaning they can move inward into the bit body.

Contact Now

Features:Our products are solutions that increase the return on your rig investment by increasing drilling efficiency and reliability. Superior quality and durability with special heat treatment and stress relief for maximum performance and hole cleaning capabilities. Thread button drill bits are made of high quality alloy steel rod and tungsten carbide. Heat treatment makes our drilling tools strong enough to handle your rock drilling needs while minimizing energy loss when drilling rock.

Contact Now