Button Configuration:T51 retrac button bits are equipped with hard and durable buttons, typically made of tungsten carbide. These buttons are strategically placed on the face of the bit for efficient rock penetration and breaking.Applications:T51 retrac button bits are suitable for various drilling applications, including blast hole drilling, exploration drilling, and production drilling in medium to hard rock formations.

Contact Now

Applications:T60 Retrac Button Bits are commonly used in percussive drilling methods like top hammer drilling.

Contact Now

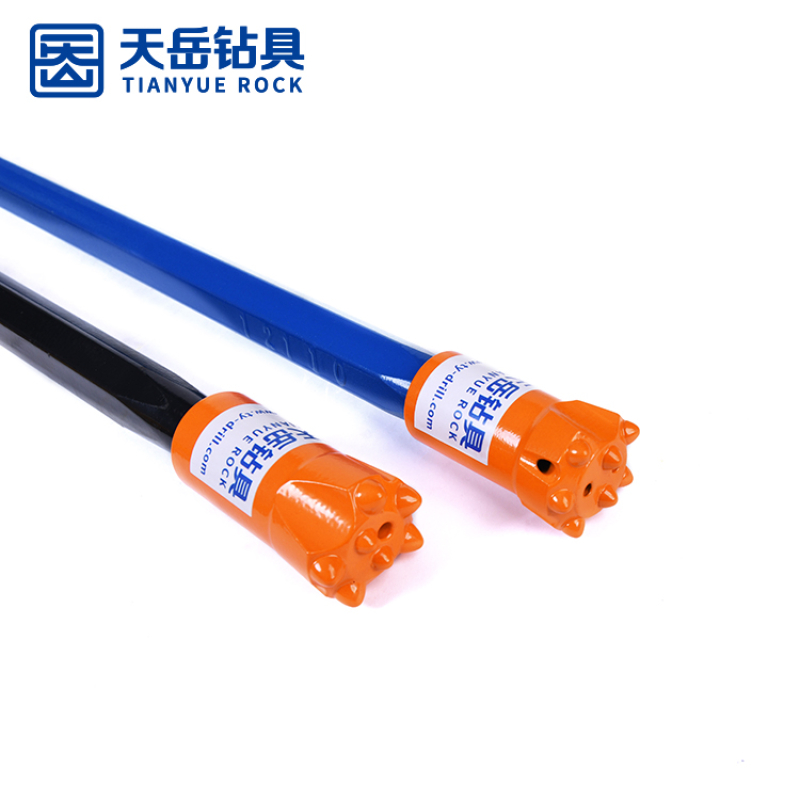

Tianyue retrac button bits are made of high-quality steel and cemented carbide as raw materials, so they have a long service life. And the use of retrac bits minimize the loss of impact energy during transmission. In addition, the advanced button fixing technology makes the fixing force uniform and not easy to loose buttons.

Contact Now

The Retrac Bits are widely applicable to mining industry, tunneling and underground engineering, open pit, construction drill,blast industry, civil engineering operations,road, gas line, pipe and trench projects,quarry work, rock anchoring and ground stabilization projects, water well industry, etc,Retrac Button BitDiameterNo×button diameterFlushing holeWeightapprox kgTIANYUE P/NmminchFrontGaugeAngleFrontSideSpherical buttons702 3/44 X 118 X 1140°2-2.51531-70T45-411/811-45-31702 3/43 X 11, 1 X 96 X 1135°3-2.51533-70T45-411/611-45-31702 3/44 X 10, 1 X 108 X 1135°4-2.51632-70T45-510/811-45-31763

Contact Now

Applications:Retrac button bits find applications in various drilling operations, including mining, quarrying, tunneling, and construction. They are suitable for drilling blast holes, anchor holes, exploration drill holes, and other rock drilling tasks.Face Design:The face design of retrac button bits may include options such as flat face, drop center, concave, or convex designs. The choice of face design depends on specific drilling requirements and the type of rock being encountered.Sizes and Variations:Retrac button bits come in various sizes to accommodate different drilling requirements.

Contact Now

A retrac button bit is a type of drill bit designed for rock drilling applications, especially in challenging and abrasive geological conditions. The term "retrac" refers to a specific design feature where the cutting buttons on the bit are retractable, meaning they can move inward into the bit body.

Contact Now

Thread Type:The "ST" in ST58 typically refers to a specific thread type, but it's important to note that variations in thread standards may exist. The "58" denotes the diameter of the thread in millimeters. The thread type is crucial for compatibility with various drilling equipment, ensuring a secure and efficient connection.Retrac Design:The retrac design is a distinctive feature of these bits. The cutting buttons on the bit are retractable, allowing them to adapt to changing rock hardness.

Contact Now

Thread Type:Retrac button bits come with specific thread types, such as R-thread (e.g., R25, R32, R38) or T-thread (e.g., T38, T45), to ensure compatibility with the drilling equipment, such as drifter rods and rock drills.Applications:Retrac button bits are commonly used in various applications, including mining, quarrying, tunneling, and construction.

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious fashions catering to your desires:introducing our mining manual tubes, to be had in a number of models in conjunction with r32, t38, t45, t51, and t60.

Contact Now

The T45-D76mm retract button bits are suitable for drilling in various types of rock formations, including hard and abrasive formations. They are widely used in mining operations, tunneling projects, and geotechnical drilling.

These button bits are precision engineered to deliver optimal cutting performance and fast penetration rates. They have a unique face design that ensures efficient rock fragmentation and improved drilling productivity.

To ensurethe longevity and performance of the T45-D76mm retract button bits, proper maintenance and care are necessary.

Contact Now

In addition to the T45 button bit for hard rock drilling mentioned earlier, we also offer a wide range of top hammer hard rock mining tools, including drilling bits, drill rods, shank adapters for drills, and coupling sleeves.

We take pride in providing the best drill bits for hard rock applications.Our selection includes various hard rock drill bits with different specifications to meet your specific needs. Thread options available include R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, among others.

Contact Now

In top hammer threaded drilling tools, standard threaded button bit is the most widely used drill bit, which can be applied to all rock conditions.

Contact Now

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's ChoiceUnlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters.

Contact Now

Features:Thread drill bits are crafted using premium alloy steel bars and tungsten carbides, ensuring their exceptional quality and durability.

By undergoing a meticulous heat treatment process, our drilling tools are capable of withstanding the most rigorous rock drilling requirements, while also minimizing energy loss during the drilling process.

Furthermore, we offer the flexibility to create customized thread button drill bits that cater to specific drilling applications.

Contact Now

Factors to Consider When Choosing Button Bits for Rock CuttingWhen selecting button bits for rock cutting, several key factors should be taken into consideration. These factors include:- Rock Formation: Understanding the geological composition of the rock formation is crucial for choosing the most suitable button bits.

Contact Now

Features:Threaded Drill Bits are essential tools used in various construction projects such as tunneling, underground mining, open pit mining, anchoring, and other large-scale construction projects. These bits come in different types including regular, retract, and reaming, each serving specific purposes. One of the key advantages of Threaded Drill Bits is their strong button-fixing ability. This feature ensures that the buttons or cutting elements of the drill bits remain securely in place, even under heavy use.

Contact Now

Material and Construction:T51 reaming drill bits are typically constructed from high-strength materials, such as tungsten carbide for the cutting edges. The body of the bit is made from alloy or tool steel to withstand the forces encountered during reaming.Applications:Reaming drill bits in mining are used for various purposes, including blast hole drilling, exploration drilling, and production drilling.

Contact Now

Features:Premium designs and high-quality materials are essential for optimal drilling performance. Tianyue is a trusted supplier of premium tungsten carbide insert grade T6 and steel, providing industry-leading strength and penetration rates. With these premium materials, you can expect increased productivity and efficiency. The excellent straightness and hole clean quality of our products ensure precise drilling operations. By choosing Tianyue, you can achieve maximum drilling performance for your rock drills.

Contact Now

Features:The threaded drill bit, equipped with the hydraulic drilling jumbo, is used for crushing rock. It is widely utilized in tunnel construction, large-scale open and underground mines, as well as for large section tunnel advancement in metal mining.Our threaded button bit is manufactured using the highest quality alloy steel bar and tungsten carbide. It undergoes a heat treatment process, ensuring its durability and performance. The threaded button bit comes in various sizes, including R25, R28, R32, R35, R38, T45, T51, ST58, GT60, ST68, and more.

Contact Now

Features:Our products are solutions that increase the return on your rig investment by increasing drilling efficiency and reliability. Superior quality and durability with special heat treatment and stress relief for maximum performance and hole cleaning capabilities. Thread button drill bits are made of high quality alloy steel rod and tungsten carbide. Heat treatment makes our drilling tools strong enough to handle your rock drilling needs while minimizing energy loss when drilling rock.

Contact Now

Versatility:Taper drill bits are versatile and can be used for a range of drilling applications, including exploration drilling, blast hole drilling, and rock drilling.Drill bitDiameterNo×button diameterFlushing holeWeight approx kgTIANYUE P/NmminchFrontGaugeAngleFrontSide Button bit,Short skirt321 1/4 1×83×835°110.241431-321122-18/38-45-51321 1/4 2×75×740°110.241431-321122-27/57-45-51331 19/642×74×740°110.251431-331122-27/47-45-51341 11/322×74×740°110.291431-341122-27/47-45-51351 3/8 2×75×735°110.331431-351122-27/57-45-51351 3/8 2×75×835°110.33

Contact Now

Unveiling Mining Excellence with Our Guide Tubes: A Game-Changer in Drilling EfficiencyVarious models catering on your wishes:introducing our mining manual tubes, available in a range of fashions along with r32, t38, t45, t51, and t60.

Contact Now

Features:Rock drilling tools, including the button bit, have a wide range of applications in different industries. They are heavily used in underground mining operations as well as tunneling and quarrying projects.

Our button bit offers a competitive advantage due to several factors. Firstly, we utilize high-grade tungsten carbide inserts that enhance its performance and longevity. Additionally, our button bit bodies are manufactured from top-quality steel and are processed using state-of-the-art CNC machinery and heat treatment techniques.

Contact Now

Features:The "Tianyue" brand rock drilling bits produced by our company have the following properties:1.High enough surface hardness. It can improve the wear resistance of rock drilling bits, the ability of rock drilling bits to resist contact fatigue and bending fatigue, and the surface has a certain plasticity, which can reduce stress concentration and improve the service life of rock drilling tools.2.Good strength and toughness matching.

Contact Now