A chisel bit is a type of rock drill bit designed for drilling into hard or abrasive materials, particularly rock. It is commonly used in mining, quarrying, and construction applications. Here are key features and information about chisel bits:

| Drill bit | Diameter | For class of rock | Tip size(mm) | Taper | Weight(kg) | TIANYUE P/N |

| mm | inch | Height×Width |

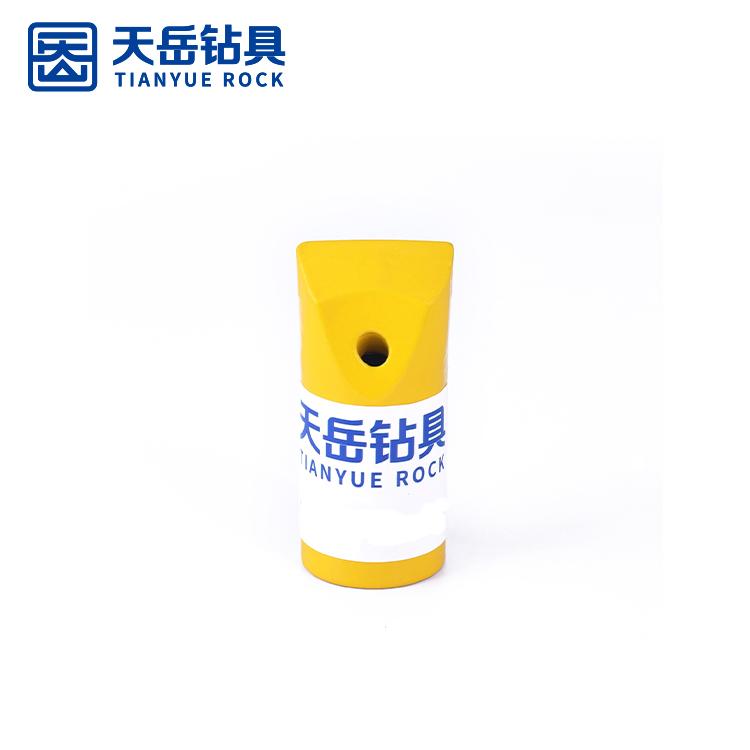

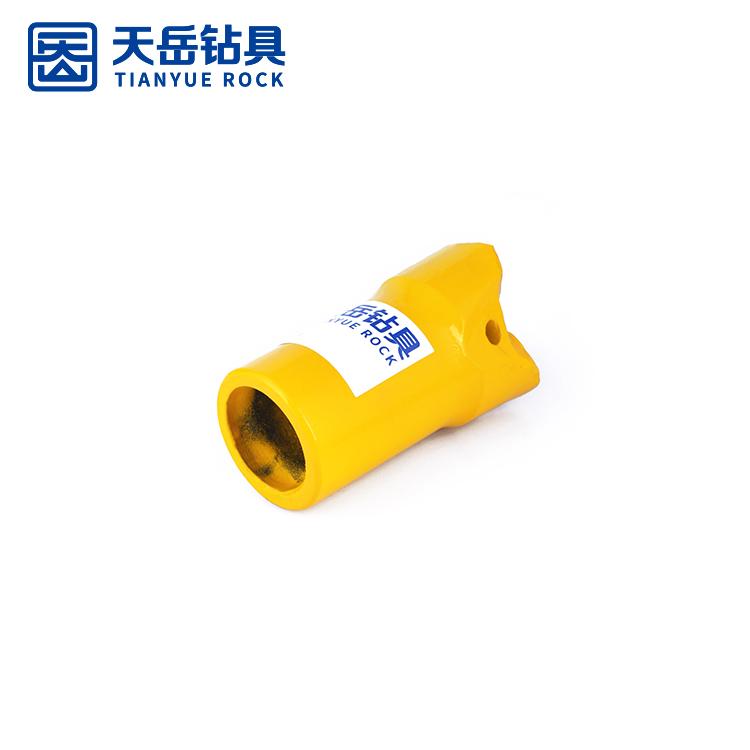

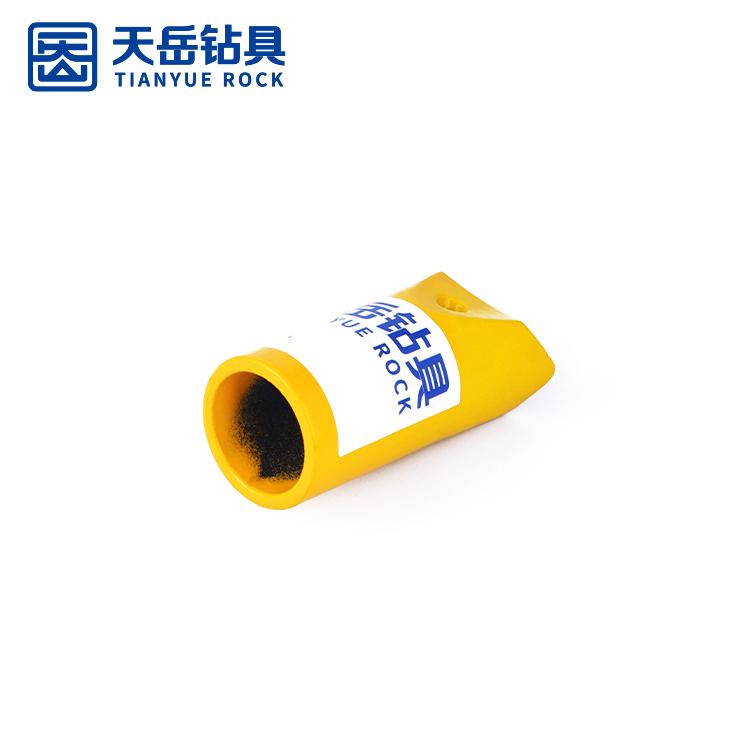

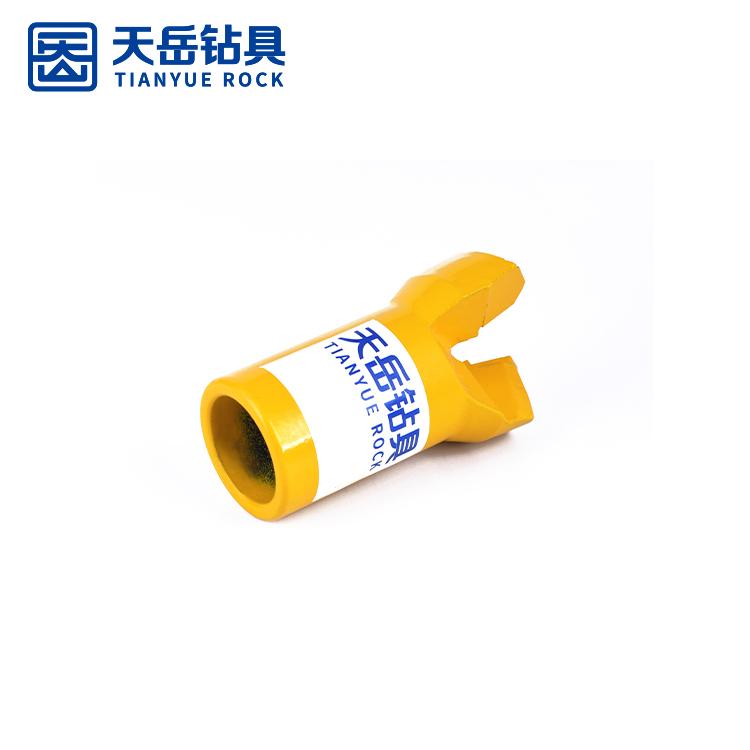

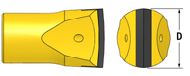

Horseshoe chisel bit

| 26 | 1 1/32 | 10-14 | 10×7 | 7° | 0.17 | 1111-26721-10/7-40-21 |

| 28 | 1 7/64 | 10-14 | 10×7 | 7° | 0.18 | 1111-28721-10/7-40-21 |

| 30 | 1 3/16 | 8-12 | 13.5×8 | 7° | 0.22 | 1111-30722-13.5/8-40-14 |

| 30 | 1 3/16 | 10-14 | 13.5×8 | 7° | 0.22 | 1111-30722-13.5/8-40-13 |

| 32 | 1 1/4 | 8-12 | 13.5×8 | 7° | 0.24 | 1111-32722-13.5/8-40-14 |

| 32 | 1 1/4 | 10-14 | 13.5×8 | 7° | 0.24 | 1111-32722-13.5/8-40-13 |

| 34 | 1 11/32 | 8-12 | 13.5×8 | 7° | 0.27 | 1111-34722-13.5/8-40-14 |

| 34 | 1 11/32 | 10-14 | 13.5×8 | 7° | 0.27 | 1111-34722-13.5/8-40-13 |

| 36 | 1 27/64 | 8-12 | 13.5×8 | 7° | 0.30 | 1111-36722-13.5/8-40-14 |

| 36 | 1 27/64 | 10-14 | 13.5×8 | 7° | 0.30 | 1111-36722-13.5/8-40-13 |

| 38 | 1 1/2 | 8-12 | 13.5×8 | 7° | 0.33 | 1111-38723-13.5/8-40-14 |

| 38 | 1 1/2 | 10-14 | 13.5×8 | 7° | 0.33 | 1111-38723-13.5/8-40-13 |

| 38 | 1 1/2 | 8-12 | 15×9 | 7° | 0.33 | 1111-38723-15/9-40-14 |

| 38 | 1 1/2 | 10-14 | 15×9 | 7° | 0.33 | 1111-38723-15/9-40-13 |

| 40 | 1 37/64 | 8-12 | 13.5×9.2 | 7° | 0.38 | 1111-40723-13.5/9.2-40-14 |

| 40 | 1 37/64 | 10-14 | 13.5×9.2 | 7° | 0.38 | 1111-40723-13.5/9.2-40-13 |

| 40 | 1 37/64 | 14-16 | 13.5×9.2 | 7° | 0.38 | 1111-40723-13.5/9.2-40-12 |

| 40 | 1 37/64 | 16-18 | 13.5×9.2 | 7° | 0.38 | 1111-40723-13.5/9.2-40-11 |

| 40 | 1 37/64 | 8-12 | 15×9.8 | 7° | 0.38 | 1111-40723-15/9.8-40-14 |

| 40 | 1 37/64 | 10-14 | 15×9.8 | 7° | 0.38 | 1111-40723-15/9.8-40-13 |

| 40 | 1 37/64 | 14-16 | 15×9.8 | 7° | 0.38 | 1111-40723-15/9.8-40-12 |

| 40 | 1 37/64 | 16-18 | 15×9.8 | 7° | 0.38 | 1111-40723-15/9.8-40-11 |

| 42 | 1 2/3 | 8-12 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13.5/9.2-40-14 |

| 42 | 1 21/32 | 10-14 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13.5/9.2-40-13 |

| 42 | 1 21/32 | 14-16 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13.5/9.2-40-12 |

| 42 | 1 21/32 | 16-18 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13.5/9.2-40-11 |

| 42 | 1 21/32 | 8-12 | 15×9.8 | 7° | 0.41 | 1111-42723-15/9.8-40-14 |

| 42 | 1 21/32 | 10-14 | 15×9.8 | 7° | 0.41 | 1111-42723-15/9.8-40-13 |

| 42 | 1 21/32 | 10-14 | 15×9.8 | 7° | 0.41 | 1111-42723-15/9.8-40-12 |

| 42 | 1 21/32 | 16-18 | 15×9.8 | 7° | 0.41 | 1111-42723-15/9.8-40-11 |

| 43 | 1 11/16 | 8-12 | 13.5×9.2 | 7° | 0.42 | 1111-43723-13.5/9.2-40-14 |

| 43 | 1 11/16 | 10-14 | 13.5×9.2 | 7° | 0.42 | 1111-43723-13.5/9.2-40-13 |

| 43 | 1 11/16 | 8-12 | 15×9.8 | 7° | 0.42 | 1111-43723-15/9.8-40-14 |

| 43 | 1 11/16 | 10-14 | 15×9.8 | 7° | 0.42 | 1111-43723-15/9.8-40-14 |

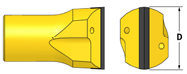

Oblique chipways chisel bit

| 20 | 25/32 | 10-14 | 12×6 | 4° | 0.1 | 1112-20415-12/6-40-22 |

| 22 | 55/64 | 10-14 | 12×6 | 4° | 0.12 | 1112-22415-12/6-40-22 |

| 24 | 15/16 | 10-14 | 12×6 | 4° | 0.14 | 1112-24415-12/6-40-22 |

| 26 | 1 1/32 | 10-14 | 12×6 | 4° | 0.16 | 1112-26415-12/6-40-22 |

| 28 | 1 7/64 | 10-14 | 13×8 | 7° | 0.19 | 1112-28722-13/8-40-22 |

| 30 | 1 3/16 | 10-14 | 13.5×8 | 7° | 0.22 | 1112-30722-13/8-40-22 |

| 32 | 1 1/4 | 10-14 | 13.5×8 | 7° | 0.24 | 1112-32722-13/8-40-22 |

| 33 | 1 19/64 | 10-14 | 13.5×8 | 7° | 0.25 | 1112-33722-13/8-40-22 |

| 34 | 1 11/32 | 10-14 | 13.5×8 | 7° | 0.27 | 1112-34722-13/8-40-22 |

| 36 | 1 27/64 | 10-14 | 13.5×8 | 7° | 0.29 | 1112-36722-13/8-40-22 |

| 38 | 1 1/2 | 10-14 | 13.5×8 | 7° | 0.34 | 1112-38723-13/8-40-22 |

| 40 | 1 37/64 | 10-14 | 13.5×9.2 | 7° | 0.4 | 1112-40723-13/9-40-22 |

| 41 | 1 5/8 | 10-14 | 13.5×9.2 | 7° | 0.41 | 1112-41723-13/9-40-22 |

| 42 | 1 21/32 | 10-14 | 13.5×9.2 | 7° | 0.43 | 1112-42723-13/9-40-22 |

Flat chipways chisel bit

| 38 | 1 1/2 | 10-14 | 16×10 | 7° | 0.36 | 1113-38723-16/10-40-22 |

| 40 | 1 37/64 | 10-14 | 16×10 | 7° | 0.38 | 1113-40723-16/10-40-22 |

| 41 | 1 5/8 | 10-14 | 16×10 | 7° | 0.41 | 1113-41723-16/10-40-22 |

| 42 | 1 21/32 | 10-14 | 16×10 | 7° | 0.43 | 1113-42723-16/10-40-22 |

| 45 | 1 3/4 | 10-14 | 22×16×10 | 7° | 0.6 | 1113-45723-16/10-40-22 |

| 46 | 1 3/4 | 10-14 | 22×16×10 | 7° | 0.61 | 1113-46723-16/10-40-22 |

| 48 | 1 7/8 | 10-14 | 22×16×10 | 7° | 0.63 | 1113-48723-16/10-40-22 |

| 50 | 1 31/32 | 10-14 | 22×16×10 | 7° | 0.65 | 1113-50723-16/10-40-22 |

| 56 | 2 1/4 | 10-14 | 24×16×10 | 7° | 0.82 | 1113-56723-16/10-40-22 |

| 60 | 2 23/64 | 10-14 | 26×16×10 | 7° | 0.91 | 1113-60723-16/10-40-22 |

| 65 | 2 1/2 | 10-14 | 26×16×10 | 7° | 1.12 | 1113-65723-16/10-40-22 |

| 80 | 3 1/8 | 10-14 | 36×16×10 | 7° | 1.4 | 1113-80723-16/10-40-22 |

Oblique-flat chipways chisel bit

| 36 | 1 27/64 | 10-14 | 15×10 | 7° | 0.4 | 1114-36725-15/10-40-22 |

| 38 | 1 1/2 | 10-14 | 15×10 | 7° | 0.42 | 1114-38725-15/10-40-22 |

| 40 | 1 37/64 | 10-14 | 15×10 | 7° | 0.45 | 1114-40725-15/10-40-22 |

| 41 | 1 5/8 | 10-14 | 15×10 | 7° | 0.47 | 1114-41725-15/10-40-22 |

| 42 | 1 21/32 | 10-14 | 15×10 | 7° | 0.49 | 1114-42725-15/10-40-22 |

| 43 | 1 11/16 | 10-14 | 15×10 | 7° | 0.51 | 1114-43725-15/10-40-22 |

Design:

1.A chisel bit typically has a flat, chisel-like shape with a sharp cutting edge.

2.The cutting edge of the chisel bit is often made of tungsten carbide inserts to provide hardness and wear resistance.

Application:

1.Chisel bits are suitable for drilling into hard and abrasive rock formations. They are commonly used in percussive drilling methods, such as jackhammer drilling or down-the-hole (DTH) drilling.

2.These bits are effective in breaking and chipping away rock to create boreholes or blast holes for various purposes, including mining, quarrying, and construction.

Drilling Method:

1.Chisel bits are typically used in rotary drilling methods where the bit is rotated to crush and break the rock.

2.In down-the-hole drilling, the chisel bit is attached to the end of the drill string and subjected to repeated impact forces as it penetrates the rock.

Material Composition:

1.Chisel bits are constructed from high-strength steel to withstand the mechanical forces and vibrations associated with drilling.

2.The cutting edge, often made of tungsten carbide or other hard materials, provides durability and resistance to wear.

Variations:

1.Chisel bits may come in various sizes and configurations to suit different drilling requirements.

2.Some chisel bits have multiple inserts, while others may have a single, larger insert.

Maintenance:

Regular maintenance is essential to keep chisel bits in optimal condition. This may include sharpening or replacing worn tungsten carbide inserts.

Chisel bits are chosen for their effectiveness in penetrating hard rock formations. The choice of drill bit depends on the specific geological conditions and the drilling method being used. It's important to follow manufacturer recommendations and guidelines for the proper use and maintenance of chisel bits to ensure efficient and safe drilling operations.

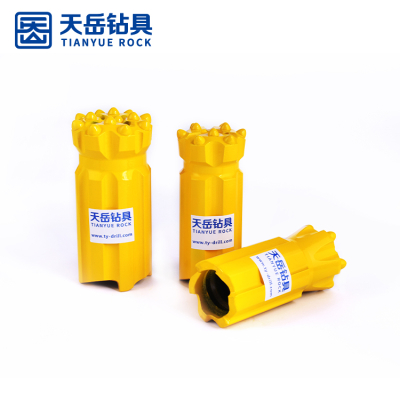

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

Chisel bits are tools commonly used in various drilling applications, including mining, construction, and exploration.

Drilling Methods:

Chisel bits can be used in various drilling methods, such as rotary drilling where the bit is rotated to grind and break the rock.

In percussive drilling methods, like jackhammer drilling or down-the-hole (DTH) drilling, the chisel bit is subjected to repeated impacts to break the rock.

It's crucial to select the appropriate type of drill bit, including chisel bits, based on the specific geological conditions and drilling requirements. Proper maintenance and adherence to manufacturer guidelines contribute to the longevity and effectiveness of chisel bits in drilling operations.