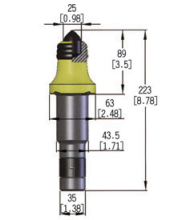

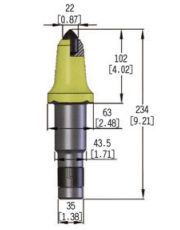

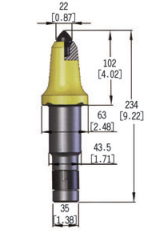

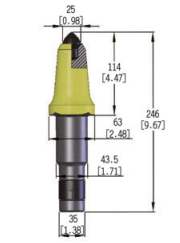

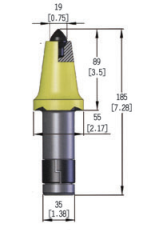

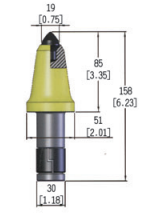

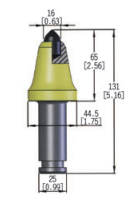

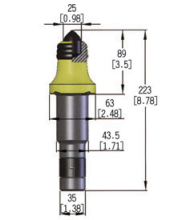

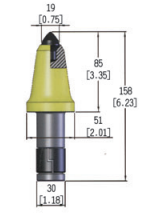

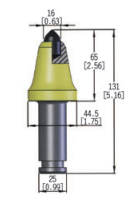

Product number | Pick length (mm) | Length of head (mm) | Pick hanldle diameter (mm) | PDC insert diameter (mm) | Pick head diameter (mm) |

U82 | 152 | 80 | 30 | 14 | 50 |

U84 | 142 | 70 | 30 | 16 | 50 |

U85 | 161 | 85 | 30 | 14 | 50 |

U92 | 195 | 101 | 35 | 16 | 55 |

U94 | 183 | 90 | 35 | 19 | 55 |

U95 | 182 | 88 | 35 | 24 | 55 |

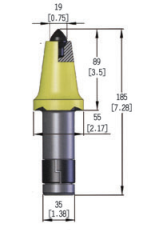

U170 | 215 | 89 | 43 | 22 | 64 |

D47 | 140 | 65 | 30 | 23 | 50 |

D120 | 143 | 68 | 30 | 16 | 55 |

D135 | 155 | 80 | 38 | 19 | 63 |

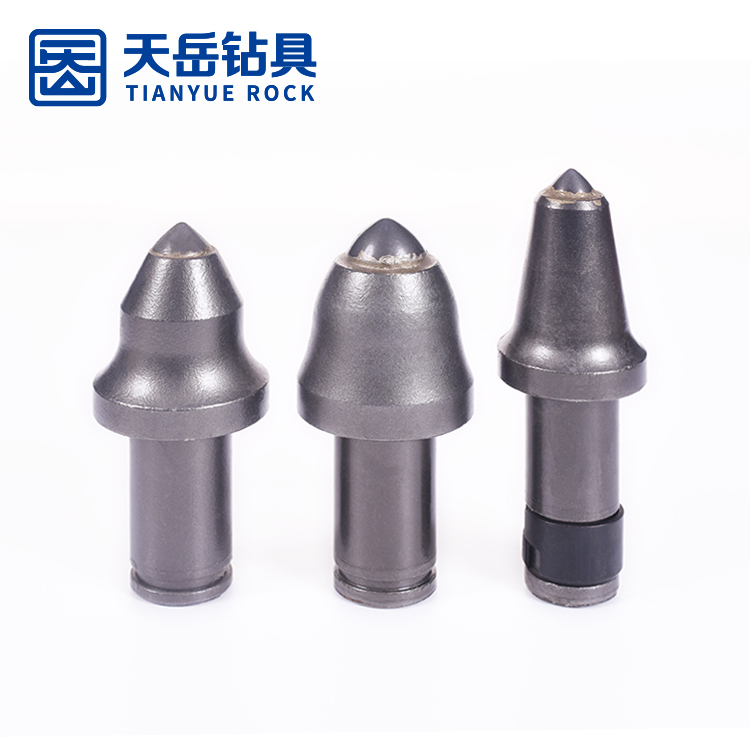

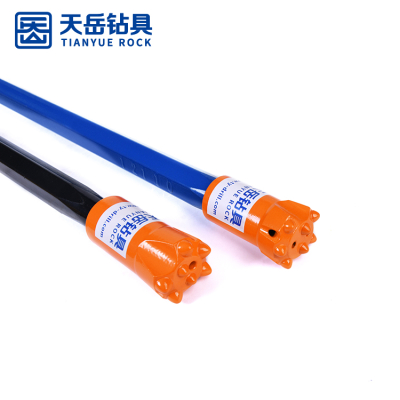

Advantages of TianYue Mining Bits:

* Quick-change connection design for easy replacement

* Forging technology provides high strength properties.

* Unique body shape designed to maximize efficiency and cuts

*Our engineering team can work with your engineering and also make sample products, to make your ideal product.

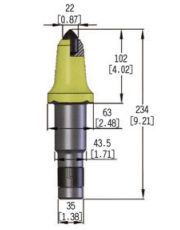

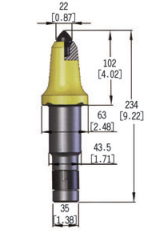

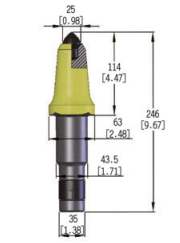

| 43mm/35mm(1.70'' /1.38'' ) step shank |

| JZ89/43-U170/Z25-42BN-3 | JZ102/43-U170/Z22-42B-3 | JZ102/43-U170/M22-42B-3 | JZ114/43-U170/M25-42B-3 |

|  |  |  |

| 35mm(1.38'') shank |

| JZ89/35-U95/Z25-42N-3 | JZ89/35-U95/Z25-23-3 | JZ89/35-U95/Z22/Z4-42N-3 | JZ89/35-U94/Z19-42B-3 |

|  |  |  |

| JZ89/35-U94/M19-42B-3 | JZ102/35-U92/M16-42-3 | JZ100/35-U92/M22-42-3 |

|

|  |  |

|

| 30mm(1.18'') shank |

| JZ70/30-U84/M19-42B-3 | JZ80/30-U84/Z16-42-3 | JZ85/30-U84/M19-42-3 | JZ70/30-U84/M19-42B-3 |

|  |  |  |

| 25mm(0.99'') shank |

| JZ64/25-U76/Z16-42-3 |

|

|

|

|

|

|

|

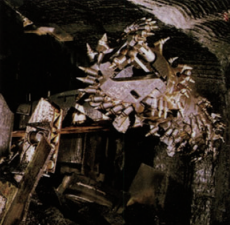

Coal mining bits, also known as coal bits or coal mining teeth, are cutting tools used in the coal mining industry to extract coal from underground or open-pit mines. These bits are an essential part of the drilling and cutting equipment used by coal miners. Here are some key features and information about coal mining bits:

Design and Structure:

Coal mining bits are designed to withstand the harsh conditions encountered in coal seams. They typically have a robust and durable structure to handle the abrasive nature of coal and rock formations.

Material:

The cutting tips or inserts of coal mining bits are often made from hard materials such as tungsten carbide. Tungsten carbide provides excellent wear resistance, hardness, and durability, making it suitable for cutting through coal and rock.

Applications:

Coal mining bits are used for drilling and cutting in coal mines. They are employed in different stages of the mining process, including drilling blast holes for explosives, extracting coal, and shaping tunnels.

Compatibility:

Coal mining bits are designed to be compatible with various drilling equipment and machines used in coal mining operations. The shank design and dimensions are crucial for proper fitment with the drilling tools.

Sizes and Configurations:

Coal mining bits come in various sizes and configurations to suit different coal seams, geological conditions, and mining methods. The selection of the appropriate bit depends on factors such as coal hardness and the specific requirements of the mining operation.

Cutting Efficiency:

The cutting efficiency of coal mining bits is a critical factor in the productivity of coal mining operations. The right bit choice ensures effective coal extraction while minimizing wear and tear.

Maintenance:

Regular inspection and maintenance of coal mining bits are essential for optimal performance and safety. Worn-out or damaged bits should be replaced promptly to maintain drilling efficiency.

Safety Considerations:

Safety is a paramount concern in coal mining. Proper training in the use of coal mining bits, as well as adherence to safety protocols, is crucial to prevent accidents and ensure the well-being of miners.

Coal mining bits play a vital role in the extraction of coal, contributing to the efficiency and productivity of mining operations. The selection of the right type, size, and quality of coal mining bits is essential for the success of coal mining projects.

Conical Pick Tools Application