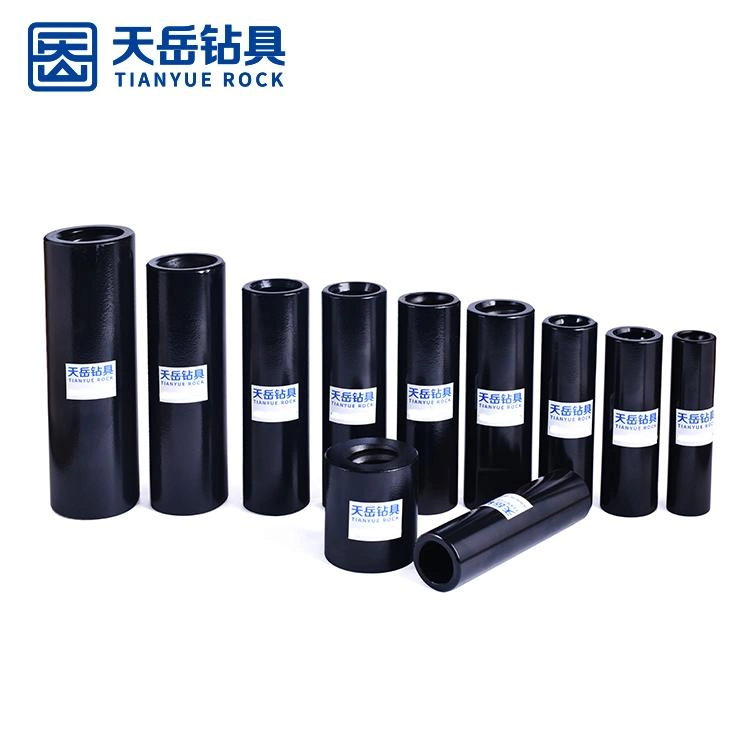

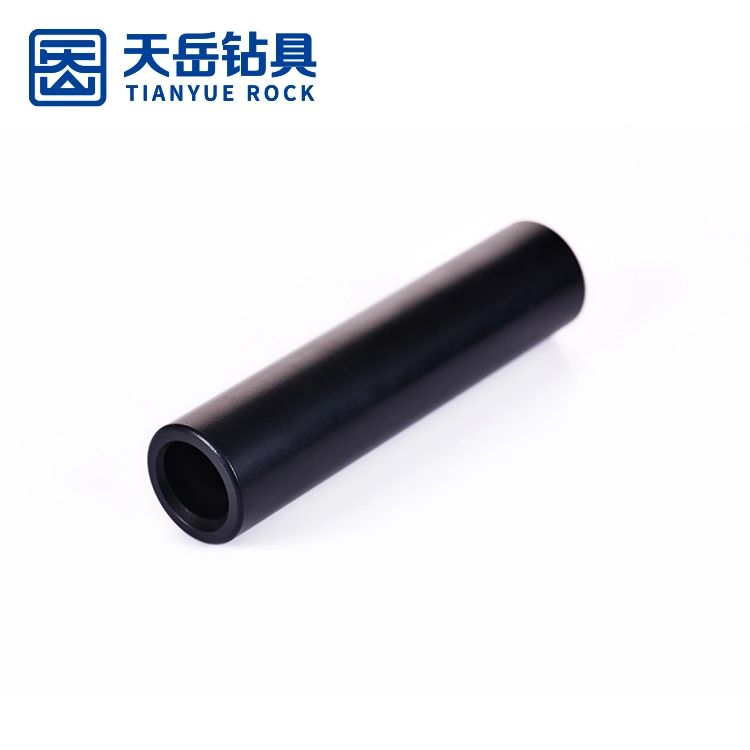

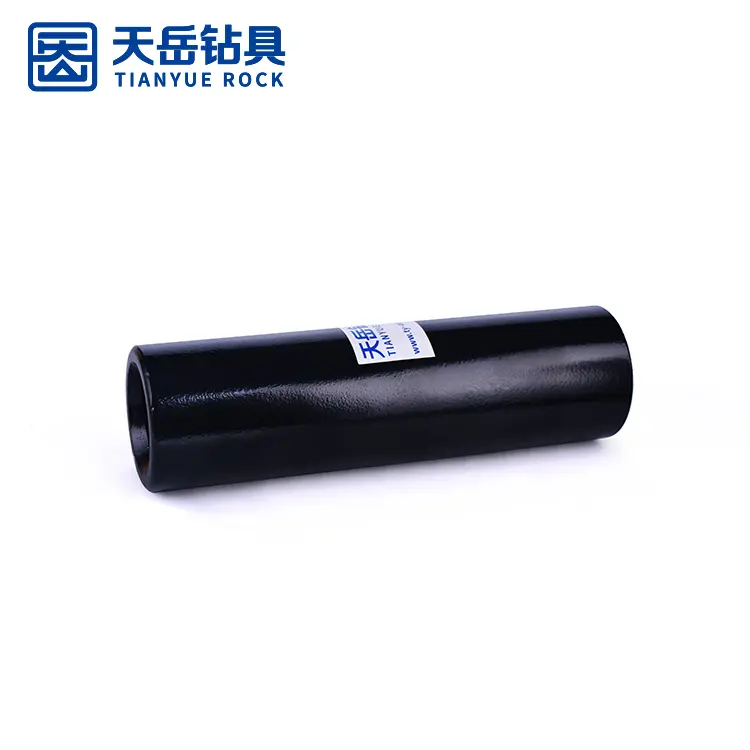

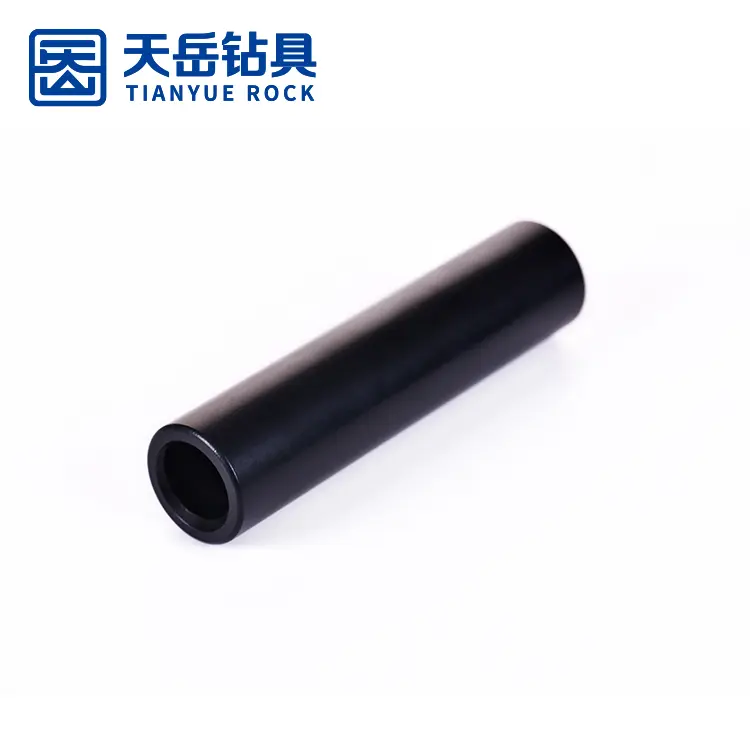

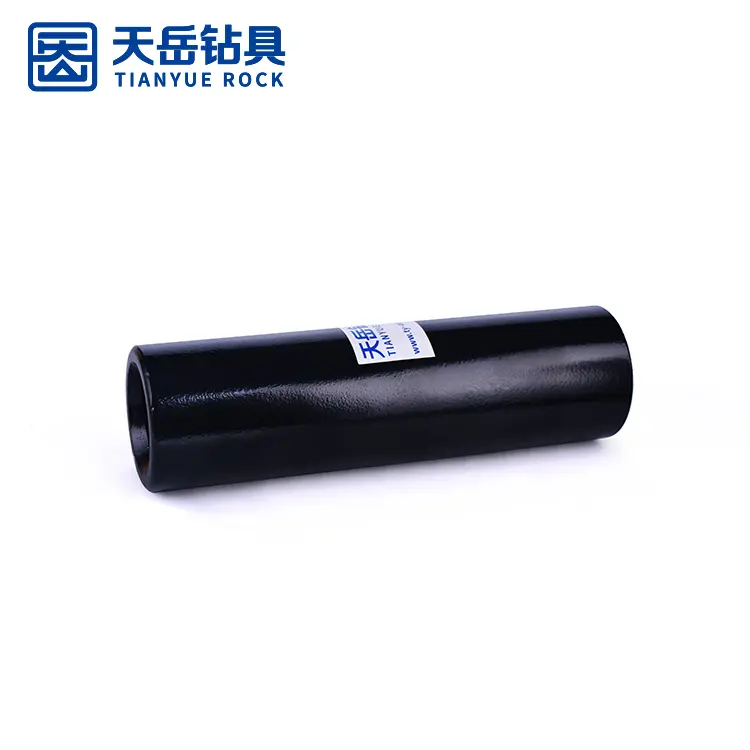

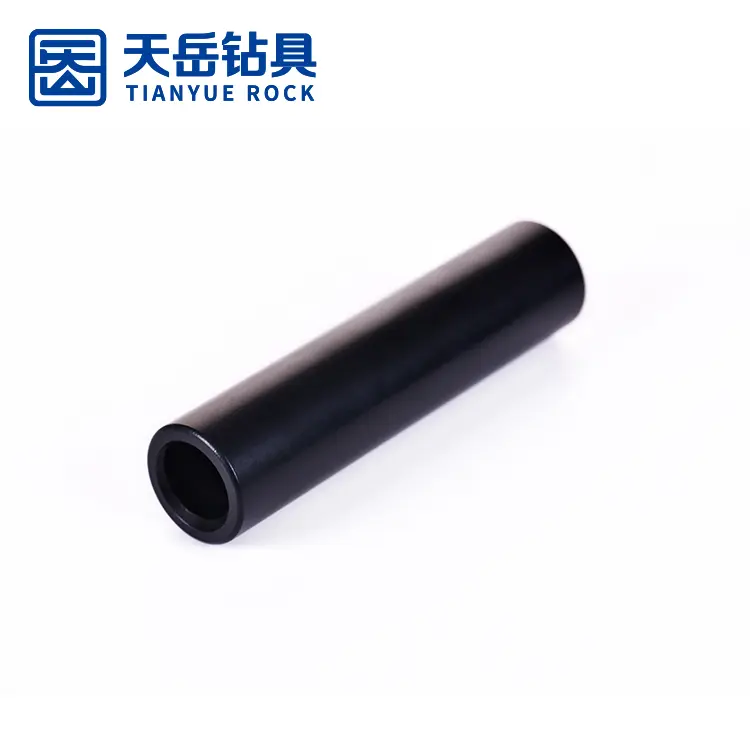

R25 Coupling Sleeves: Seamless Connections for Efficient Drilling

In the realm of drilling excellence, the R25 Coupling Sleeves stand as a testament to precision engineering and unwavering reliability. Tailored for optimal performance in a myriad of construction applications, these coupling sleeves are the linchpin for connecting drill rods and shank adapters with unparalleled efficiency.

Product | Coupling Sleeves |

Other Names | Coupling sleeves,Drill bit adapter,Rock drill tools,Tophammer drill tools,Drifter drill tools,Coupling,Drill rod couplings,Drill coupling sleeves |

Material | 23CrNi3Mo |

Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

Thread | R25, R32, R35, R38, T38, T45, T51 |

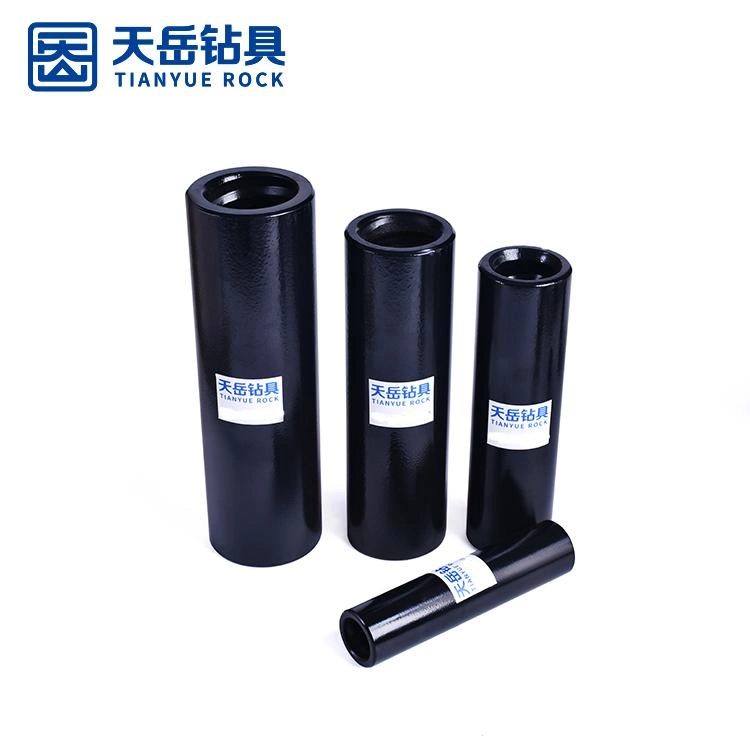

Coupling Type | Full bridge coupling sleeve

Reducing coupling sleeve(Ctossover couplings,Adapter couplings,Reduction couplings,Reducer coupling)

Standard couplings(Semi bridge couplings) |

Length | 150mm~235mm |

Diameter | 33mm~72mm |

Custom Design | Size,Color,Diameter,Thread,Length |

| Coupling | Length | Diameter | Thread | Weight

approx

kg | TIANYUE P/N |

| mm | inch | mm | inch |

Coupling sleeves

| 155 | 6 1/8 | 44 | 1 3/4 | R32 | 1.0 | 31-R32-44-155-23 |

| 150 | 5 7/8 | 35 | 1 3/8 | R25 | 0.7 | 31-R25-35-150-23 |

| 160 | 6 5/16 | 38 | 1 1/2 | R25 | 1.3 | 31-R25-38-160-23 |

Coupling sleeves of different diameter

| 150 | 5 7/8 | 45 | 1 3/4 | R25-R32 | 1.1 | 33-R25/R32-45-150-23 |

| 160 | 6 5/16 | 45 | 1 3/4 | R25-R32 | 1.2 | 33-R25/R32-45-160-23 |

| 160 | 6 5/16 | 56 | 1 13/64 | R25-R38 | 2.5 | 33-R25/R38-56-160-23 |

| 170 | 6 3/4 | 56 | 1 13/64 | R25-T38 | 3.2 | 33-R25/T38-56-170-23 |

Features and Benefits:

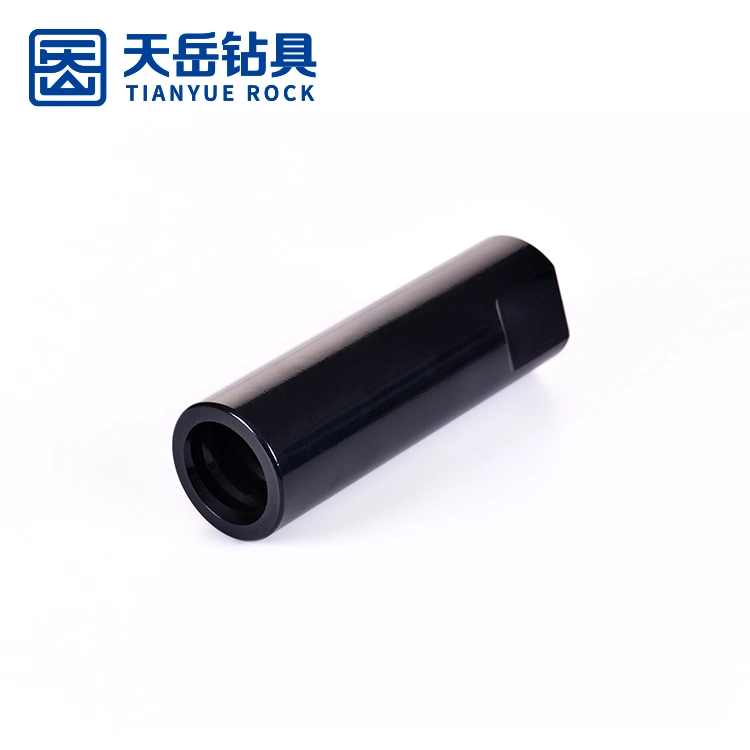

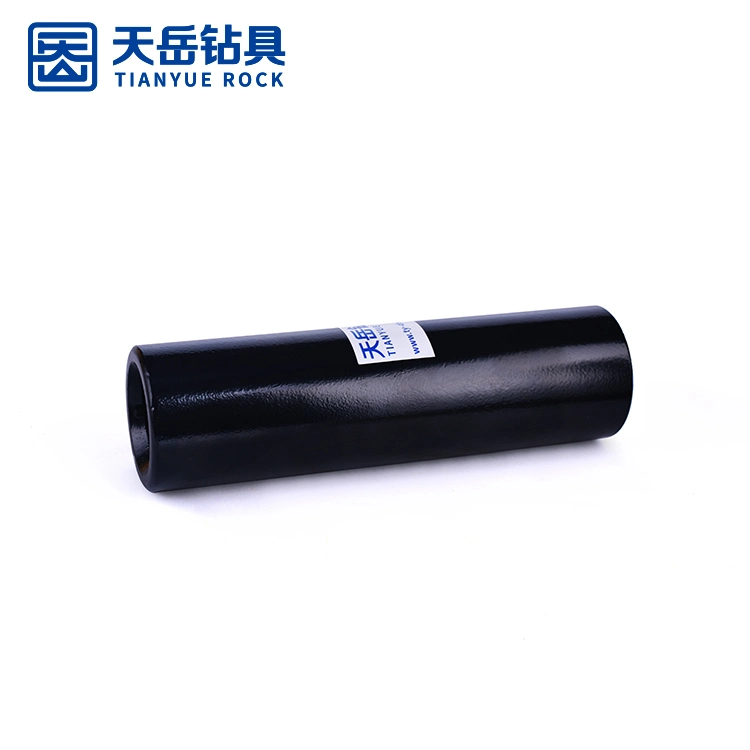

Precision Craftsmanship:Crafted with precision and attention to detail, the R25 Coupling Sleeves boast impeccable workmanship. The internal threads are engineered to perfection, ensuring a snug fit and seamless connection, guaranteeing stability and durability in every operation.

Versatile Applications:From open pit mining to tunnel engineering and quarrying, the R25 Coupling Sleeves excel in various construction projects. Their adaptability makes them indispensable, providing a reliable link between drill rods and shank adapters in diverse working environments.

Effortless Dismantling:Designed for practicality, these coupling sleeves feature an easy-to-dismantle design. This facilitates quick assembly and disassembly on the field, saving valuable time and ensuring smooth workflow in open-air construction scenarios.

Reduced Sticking Risk:The full bridge design of the R25 Coupling Sleeves minimizes the risk of getting stuck during operations. This crucial feature adds an extra layer of safety and reliability, making them an ideal choice for projects where uninterrupted drilling is paramount.

Thread Size Options:Meeting the demands of diverse construction needs, the R25 Coupling Sleeves are available in the R25 thread size. This standardized sizing ensures compatibility and interchangeability with various drilling equipment, providing a versatile solution for contractors and engineers.

Coupling Type |

| R:R25,R28,R32,R38

|

| T:T38,T45,T51 |

Applications:

Open Pit Mining

Underground Mining

Roadway Excavation

Anchoring Engineering

Blast Furnace Taphole

Tunnel Engineering

Hydropower Projects

Quarrying

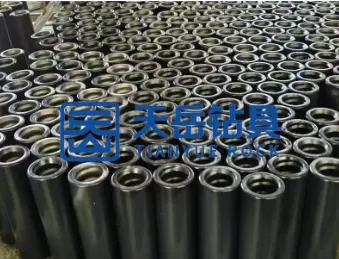

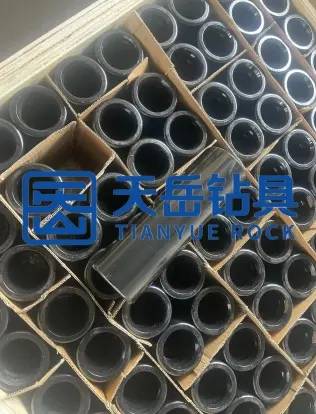

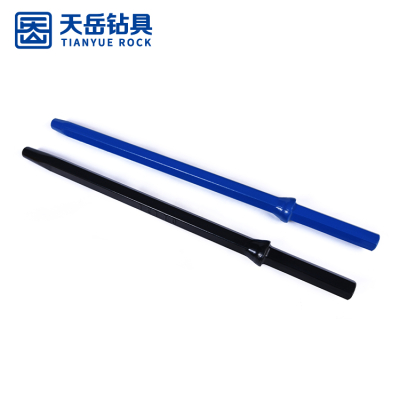

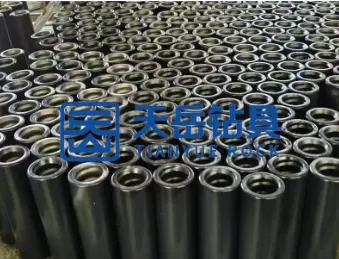

Actual pictures of drill rods |

| R25,R28,R32,R38 |

| T38,T45,T51 |

Embrace the precision, reliability, and versatility of R25 Coupling Sleeves—your indispensable partner for seamless connections in the world of drilling excellence. Elevate your construction projects with the assurance of a steadfast link between drill rods and shank adapters..

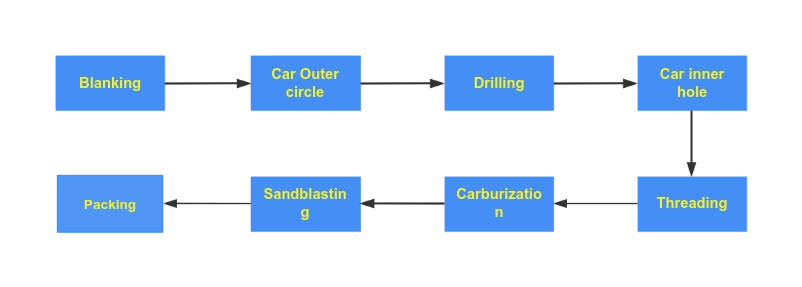

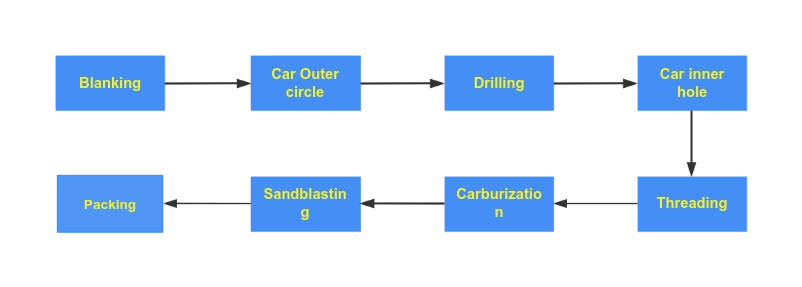

Rod Process Flow

About us

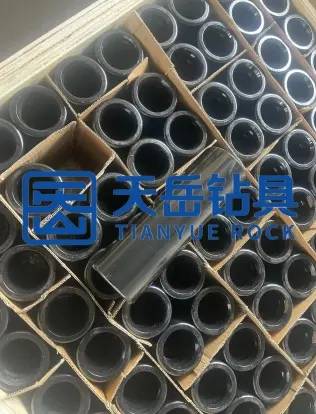

Packing

FAQ

Q1. How can we guarantee quality?Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q2. Are you factory or trade company?

Yes, we are factory with around 20years high quality mine tool drill tools.

Q3. Why should you buy from us not from other suppliers?our factory has been specialized in manufacturing drilling tools since 2000.

we have advanced technology and equipment.

our technician has more that 10 years professtional working experience.

rock drilling tools are exported throughout the world.Q4. What kind of payment terms do you offer and what is your best payment terms?

We offer different payment terms, including T/T, D/A, D/P, L/C and O/A, etc.

Our best payment terms is 120 days after shipping date for our distributors and sole distributors.

Choose Coupling Sleeve for reliability and longevity. We are committed to providing you with excellent products and services, ensuring that your mechanical equipment maintains efficient and reliable operation at all times.