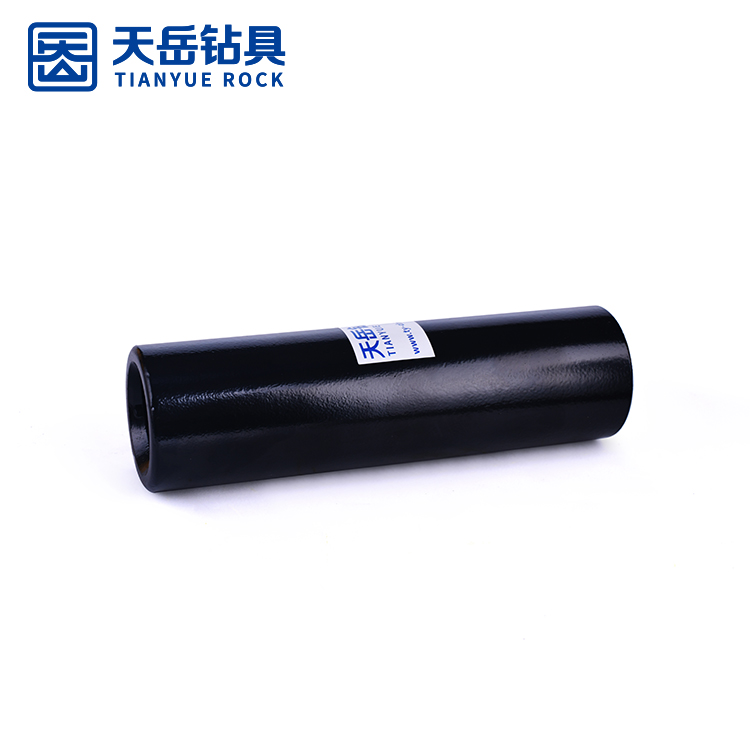

Drill Coupling Sleeves:In drilling applications, coupling sleeves are used to connect and join drill rods. This helps maintain the continuity of the drill string during drilling operations.

Product | Coupling Sleeves |

Other Names | Coupling sleeves,Drill bit adapter,Rock drill tools,Tophammer drill tools,Drifter drill tools,Coupling,Drill rod couplings,Drill coupling sleeves |

Material | 23CrNi3Mo |

Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

Thread | R25, R32, R35, R38, T38, T45, T51 |

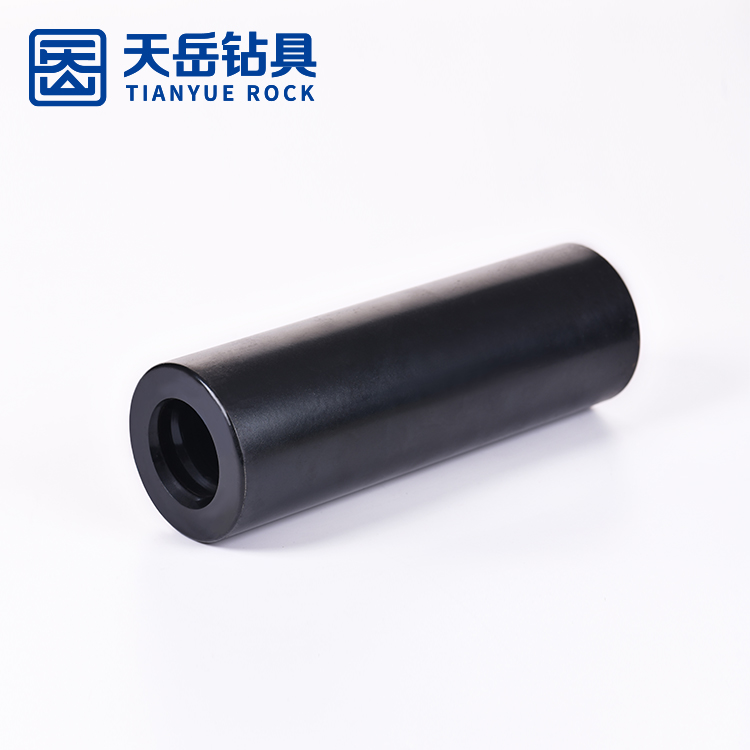

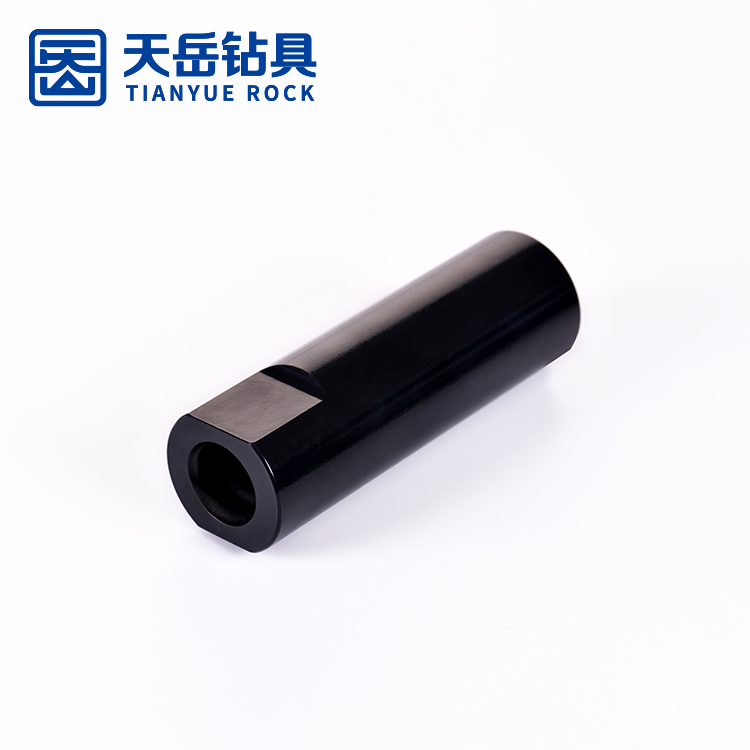

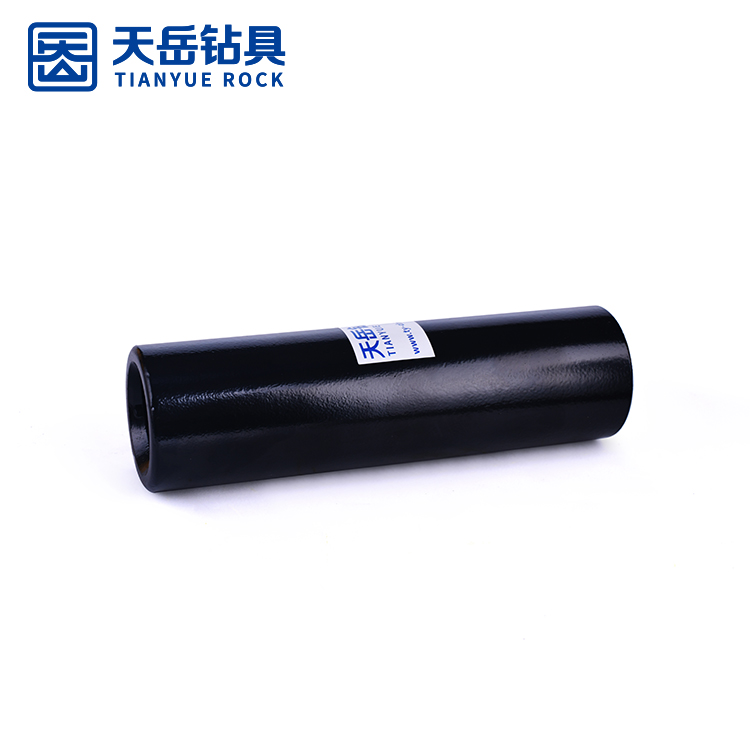

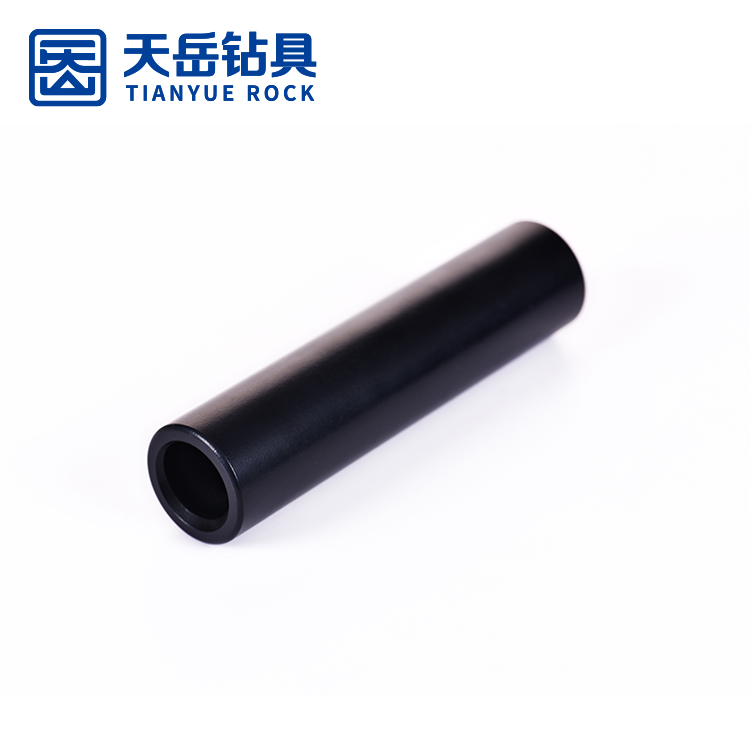

Coupling Type | Full bridge coupling sleeve

Reducing coupling sleeve(Ctossover couplings,Adapter couplings,Reduction couplings,Reducer coupling)

Standard couplings(Semi bridge couplings) |

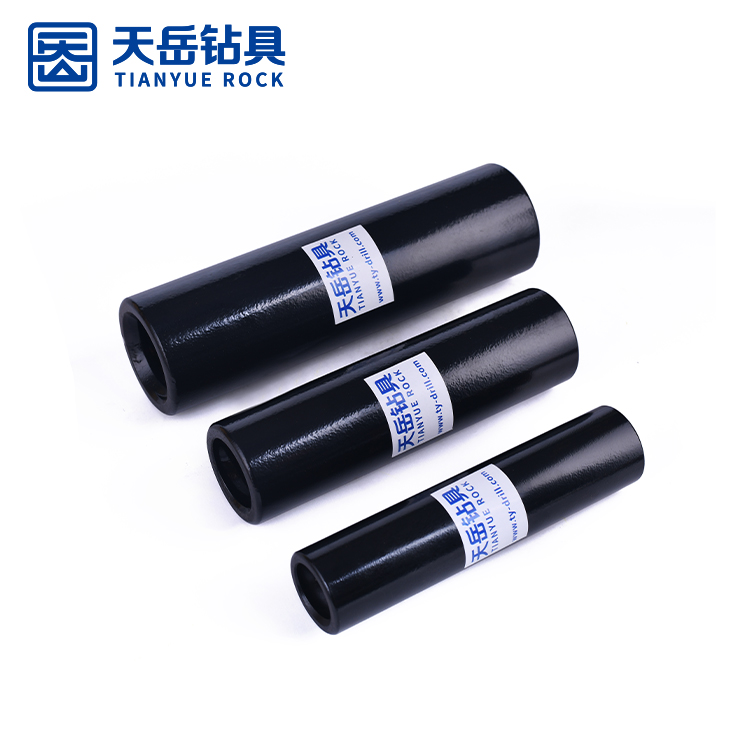

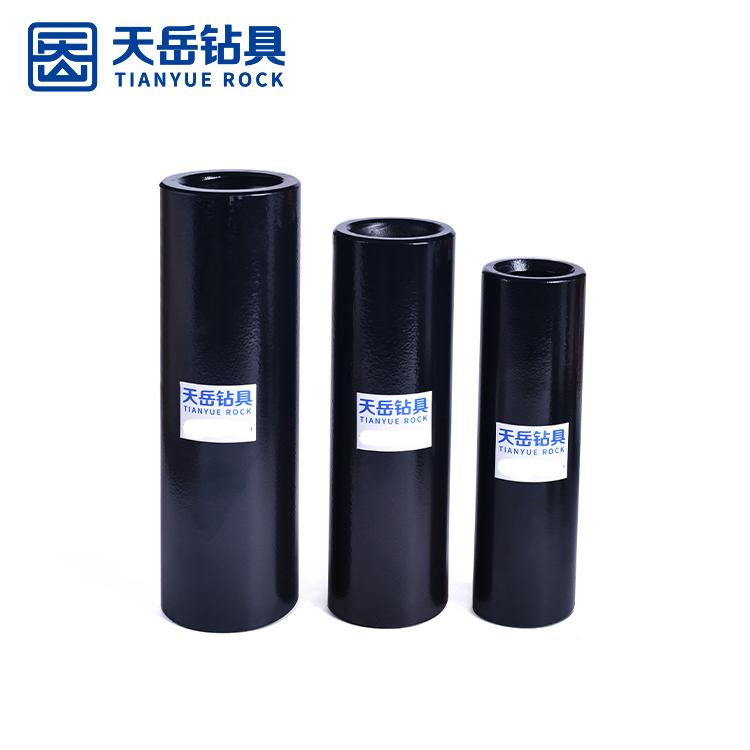

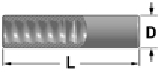

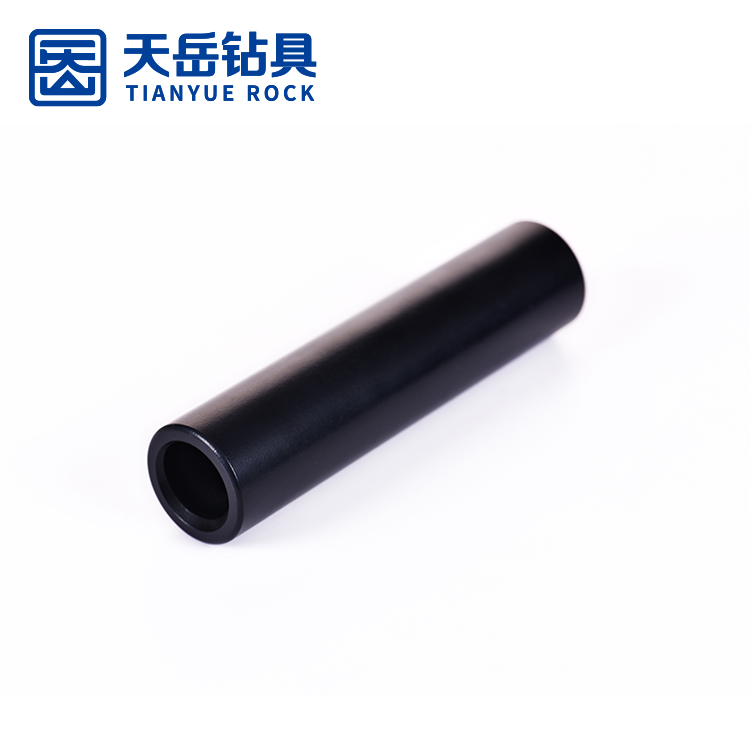

Length | 150mm~235mm |

Diameter | 33mm~72mm |

Custom Design | Size,Color,Diameter,Thread,Length |

| Coupling | Length | Diameter | Thread | Weight

approx

kg | TIANYUE P/N |

| mm | inch | mm | inch |

| 190 | 7 1/2 | 55 | 2 5/32 | T38 | 2.1 | 31-T38-55-190-23 |

Material and Construction:

Like other coupling sleeves, T38 coupling sleeves are typically constructed from high-strength steel to withstand the rigors of drilling operations. The material's durability ensures the longevity of the coupling sleeve in demanding environments.

Function:

The primary function of a T38 coupling sleeve is to connect two threaded components, usually drill rods. This connection is vital for maintaining the integrity and alignment of the entire drill string. The coupling sleeve facilitates the transfer of rotation and torque from the drilling rig to the drill bit.

Coupling Type |

| R:R25,R28,R32,R38

|

| T:T38,T45,T51 |

Compatibility:

It is crucial to ensure that the T38 coupling sleeve is compatible with the specific drill rods and drill bits being used. Standardized thread types like T38 contribute to the interchangeability of components within compatible drilling equipment.

Usage Considerations:

When using T38 coupling sleeves, adherence to manufacturer guidelines and specifications is essential. Proper installation and maintenance practices help ensure the efficiency and safety of drilling operations.

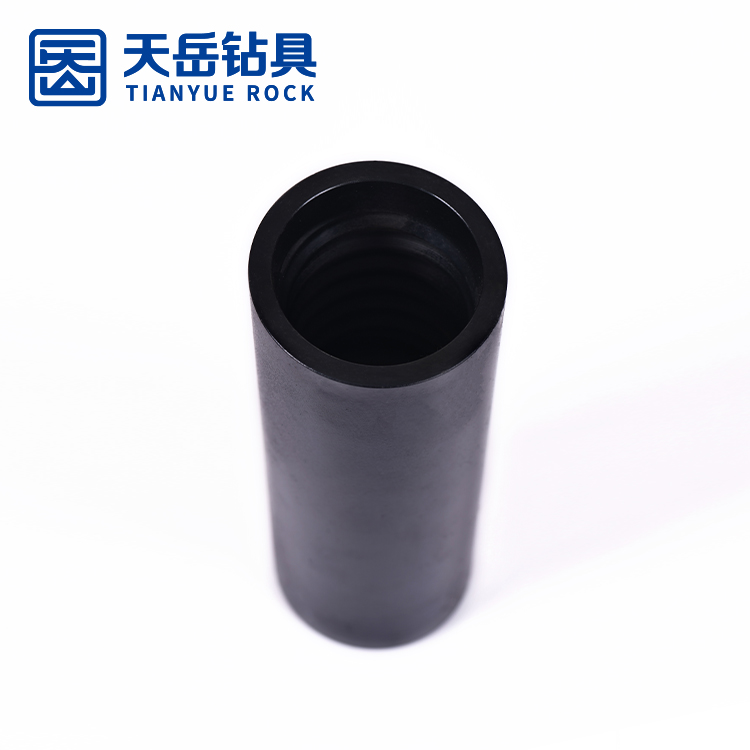

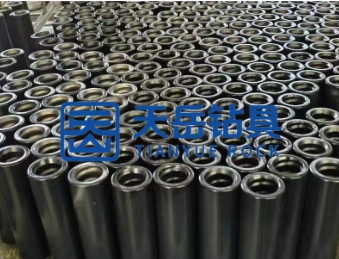

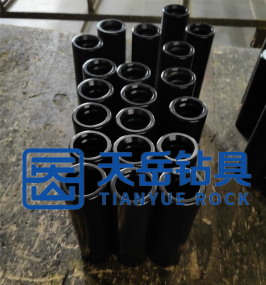

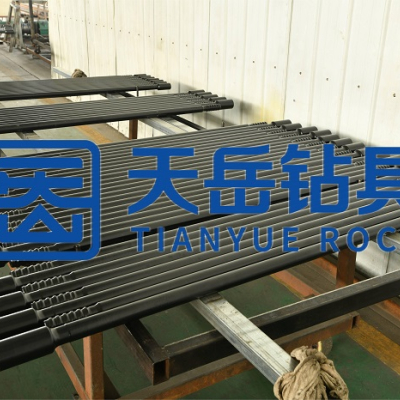

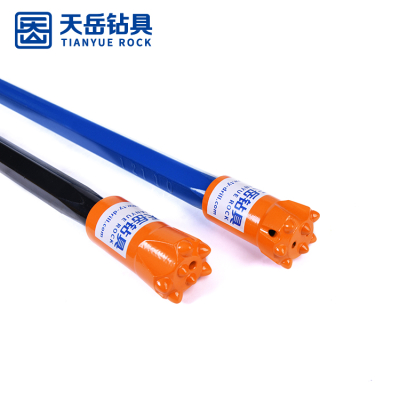

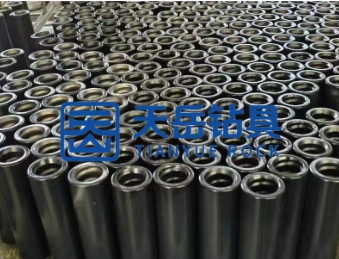

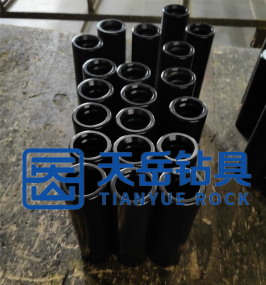

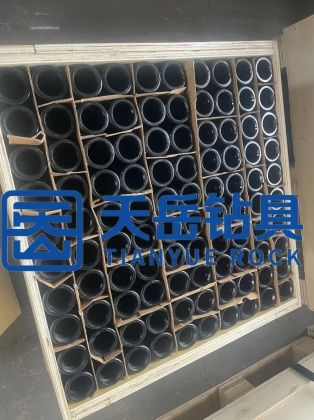

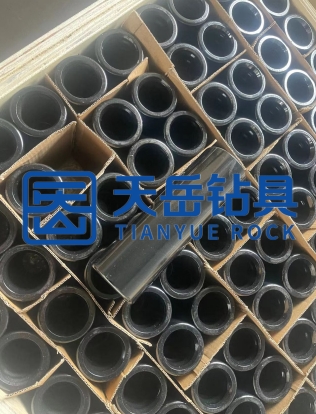

Actual pictures of drill rods |

| R25,R28,R32,R38 |

| T38,T45,T51 |

In summary, T38 coupling sleeves play a crucial role in connecting drill rods in rock drilling applications. Their robust construction and compatibility with standardized thread types make them integral components in the drilling process.

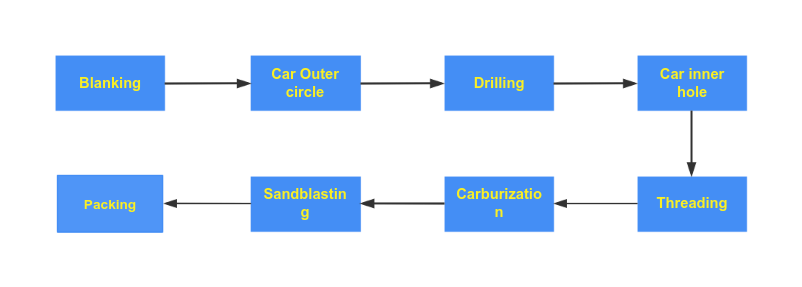

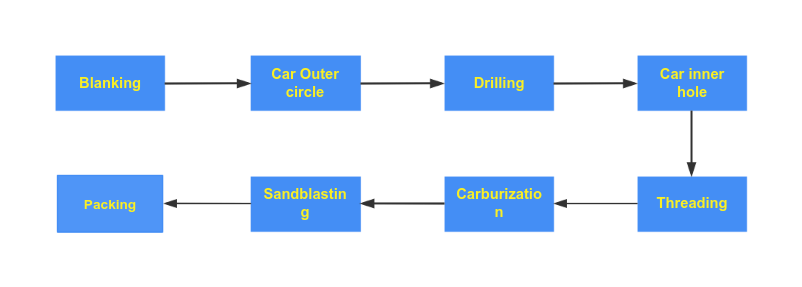

Coupling Sleeves Process Flow

About us

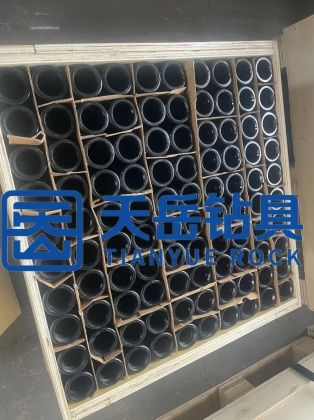

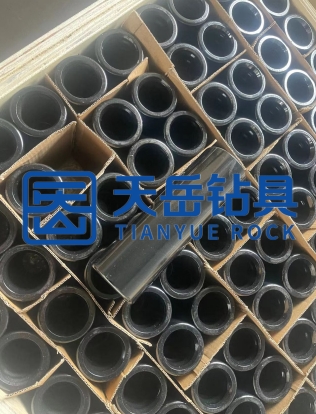

Packing

T38 coupling sleeves, also known as T38 extension rods, are commonly used in mining and drilling applications. They play a crucial role in connecting drill bits and drilling rods, ensuring a stable and efficient drilling process.

Here are some key features and benefits of T38 coupling sleeves:

1. High durability: T38 coupling sleeves are made from high-quality materials, such as alloy steel, to ensure their strength and durability. This allows them to withstand the rigors of heavy-duty drilling operations.

2. Easy installation: T38 coupling sleeves are designed for easy installation and removal. They typically feature a simple threaded connection, allowing for quick and hassle-free assembly.

3. Compatibility: T38 coupling sleeves are compatible with T38 thread drill bits and rods, making them versatile and widely used in various drilling applications.

4. Increased drilling efficiency: By securely connecting drill bits and rods, T38 coupling sleeves help to improve drilling efficiency. They minimize energy loss and vibration, ensuring a smooth and effective drilling process.

5. Cost-effective: T38 coupling sleeves provide a cost-effective solution for drilling operations. Their durability and compatibility save both time and money, as they reduce the need for frequent replacements and ensure compatibility with existing drilling equipment.

It's important to note that T38 coupling sleeves come in different lengths and designs to cater to various drilling requirements. Before purchasing, it is recommended to consult with a drilling equipment supplier or manufacturer to ensure you choose the appropriate coupling sleeves for your specific needs.