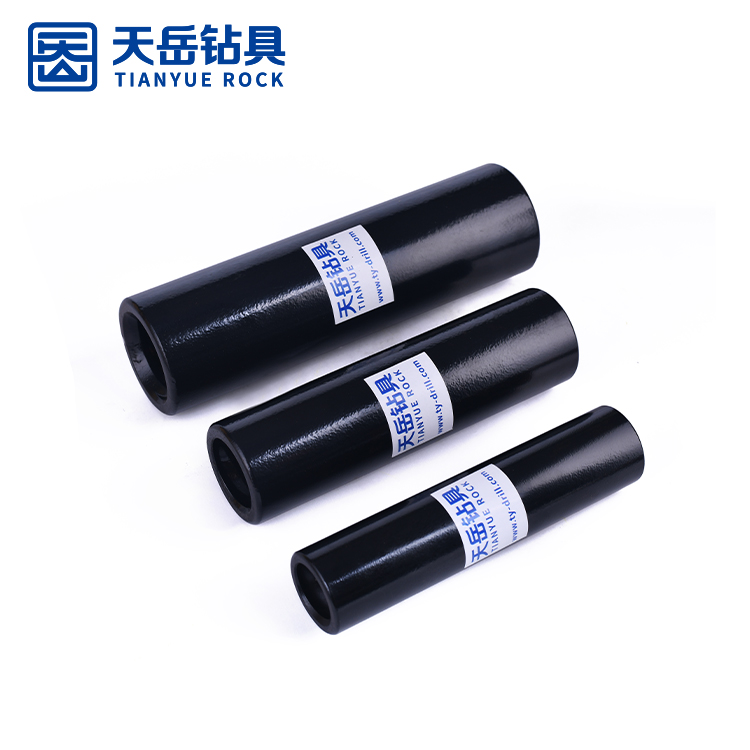

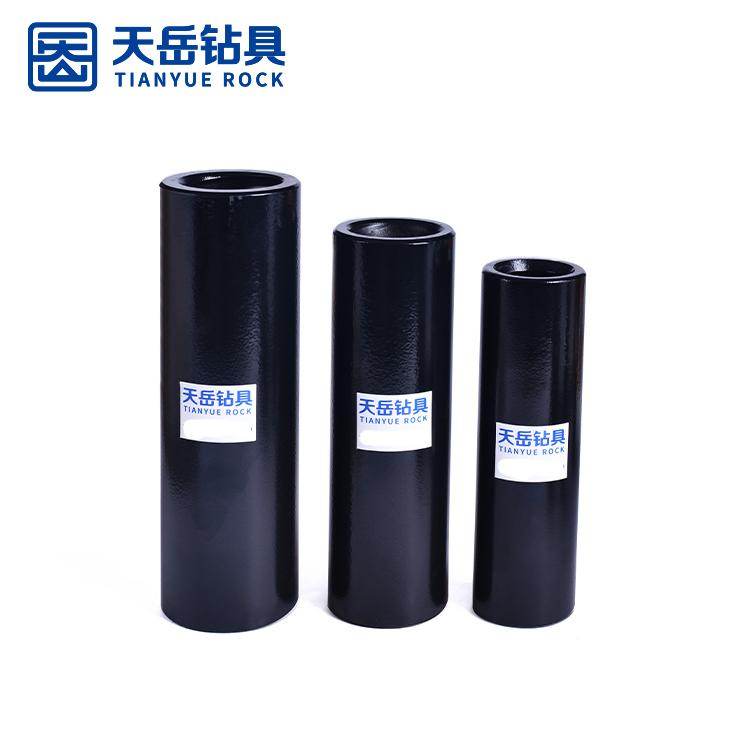

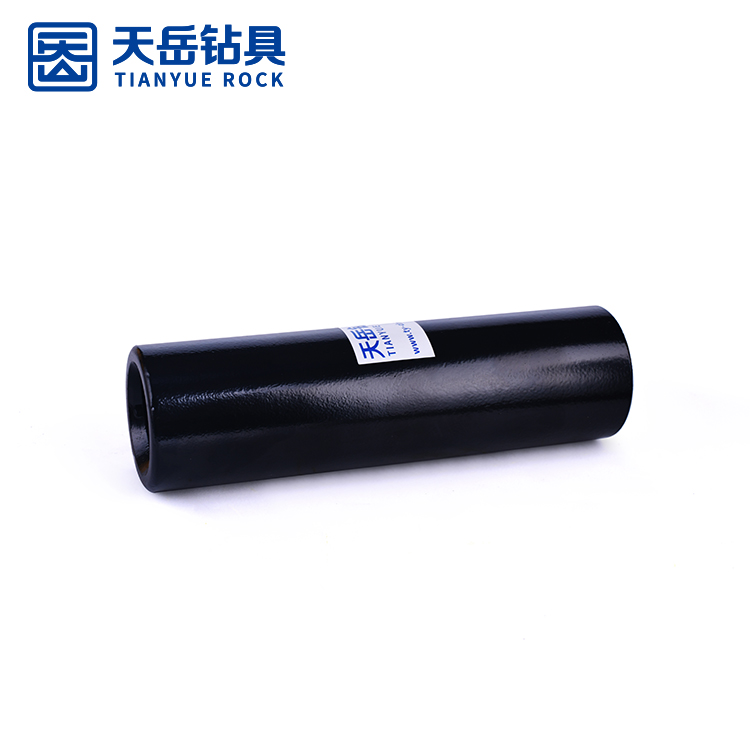

Master T45 Coupling Sleeves for Precision Drilling and Outstanding Performance

In the realm of drilling, T45 Coupling Sleeves achieve exceptional precision and reliability, injecting robust power into your projects. Serving as a critical component linking drill rods and cone adapters, T45 Coupling Sleeves stand out for their outstanding performance in fields such as mining, tunnel engineering, and underground excavation.

Product | Coupling Sleeves |

Other Names | Coupling sleeves,Drill bit adapter,Rock drill tools,Tophammer drill tools,Drifter drill tools,Coupling,Drill rod couplings,Drill coupling sleeves |

Material | 23CrNi3Mo |

Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

Thread | R25, R32, R35, R38, T38, T45, T51 |

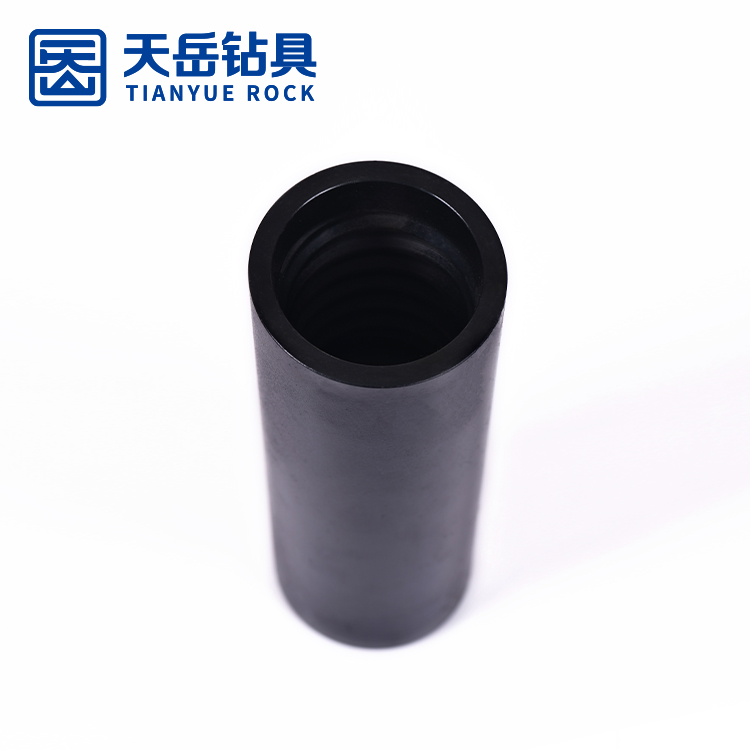

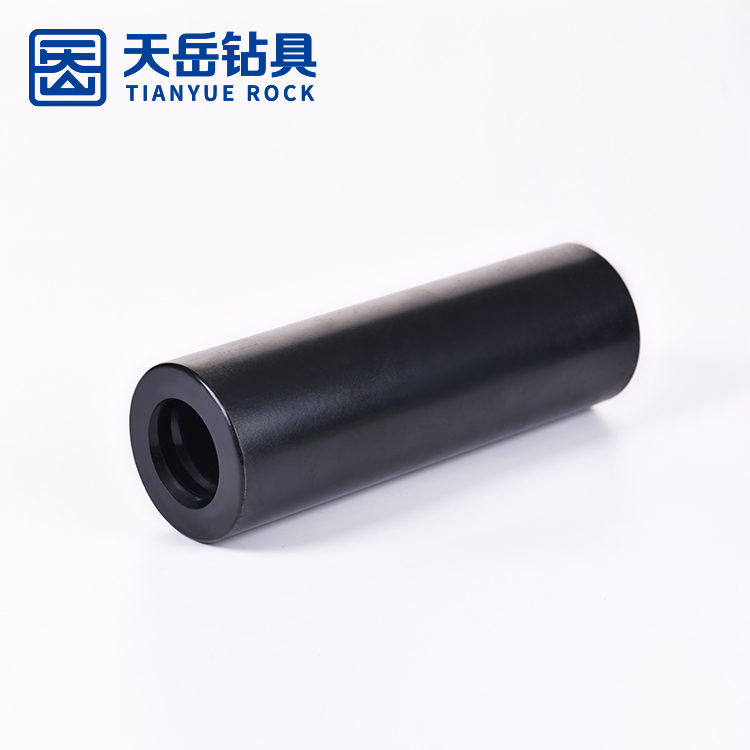

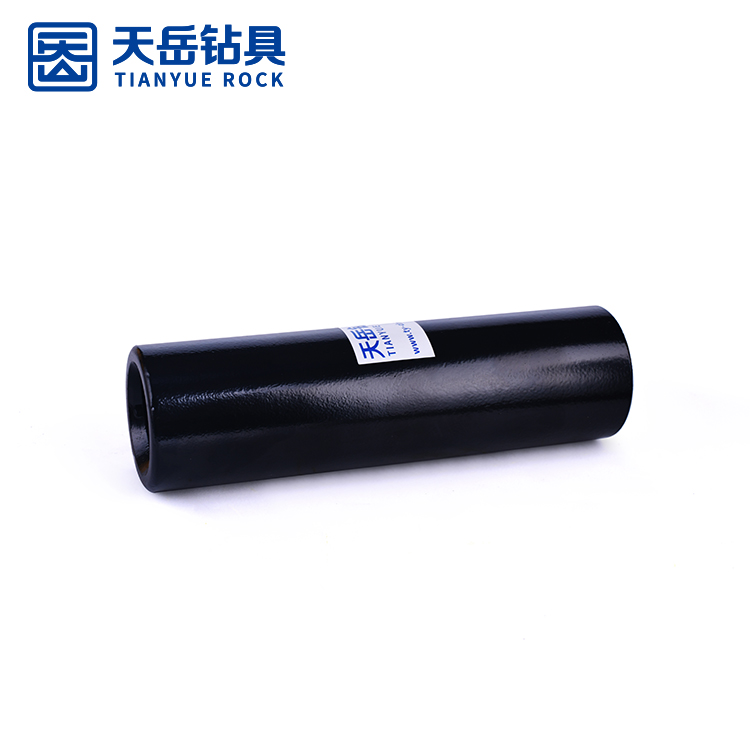

Coupling Type | Full bridge coupling sleeve

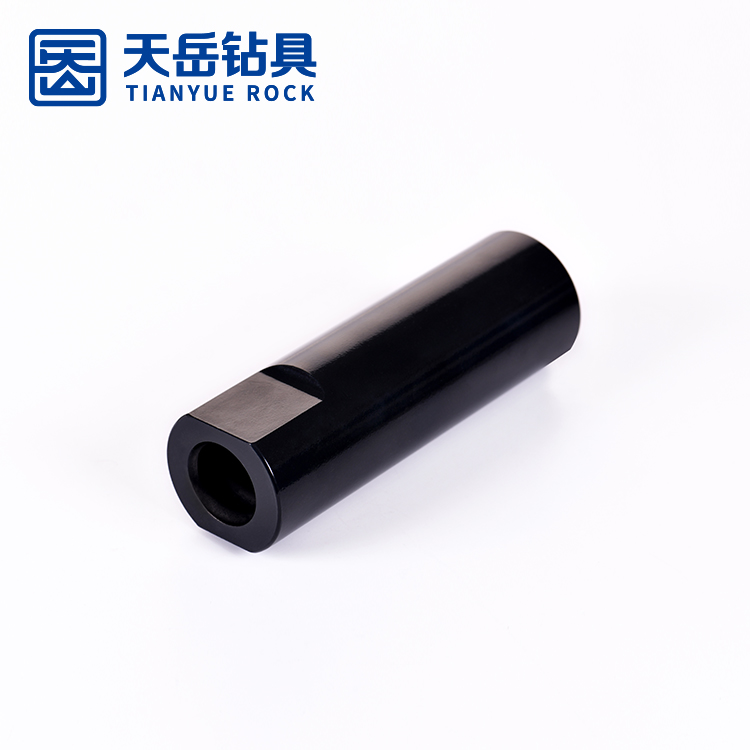

Reducing coupling sleeve(Ctossover couplings,Adapter couplings,Reduction couplings,Reducer coupling)

Standard couplings(Semi bridge couplings) |

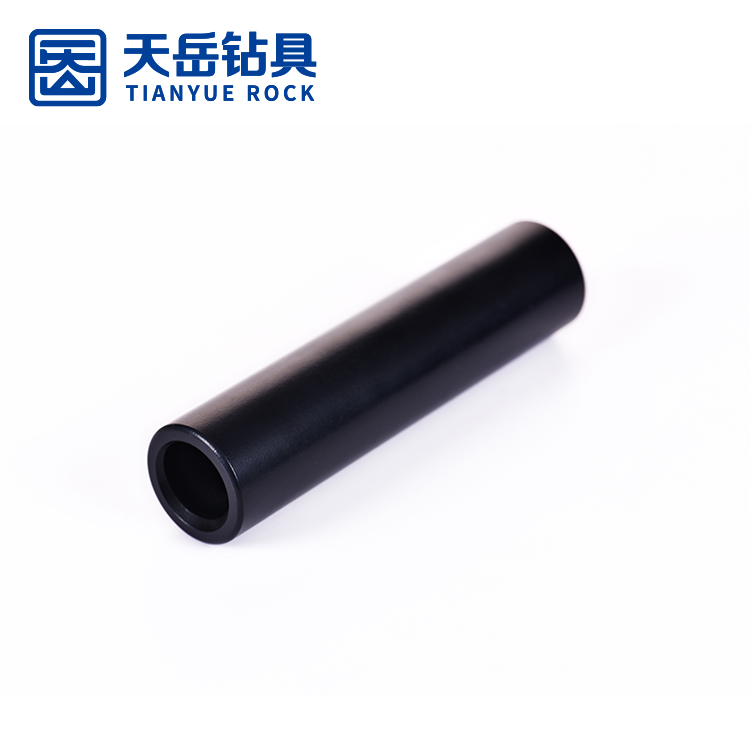

Length | 150mm~235mm |

Diameter | 33mm~72mm |

Custom Design | Size,Color,Diameter,Thread,Length |

| Coupling | Length | Diameter | Thread | Weight

approx

kg | TIANYUE P/N |

| mm | inch | mm | inch |

Coupling sleeves Coupling sleeves | 210 | 8 1/4 | 63 | 2 33/64 | T45 | 3.0 | 31-T45-63-210-23 |

| 210 | 8 1/4 | 66 | 2 37/64 | T45 | 3.3 | 31-T45-66-210-23 |

Features and Benefits:

Precision Design, Seamless Connection:The precisely engineered internal threads of T45 Coupling Sleeves ensure a tight connection between drill rods and cone adapters, providing highly accurate support for your drilling operations.

Durable Structure, Enduring Performance:Designed with durability in mind, T45 Coupling Sleeves undergo meticulous engineering to deliver lasting performance in the most challenging construction applications. Offering robust support for professional projects.

Versatile Applications, Comprehensive Adaptability:Tailored for mining, tunnel engineering, underground excavation, and more, T45 Coupling Sleeves showcase exceptional adaptability, meeting various drilling requirements in different construction projects.

Full Bridge Design, Expanding Horizons:The full bridge design ensures T45 Coupling Sleeves excel in open-air construction. Easy dismantling, secure connections, and minimized risks of entanglement contribute to an efficient and safe drilling experience.

Different Thread Designs, Flexible Variability:Opt for reducing coupling sleeves with different thread designs to achieve flexible connections with compatible products under specific conditions, expanding the application scope of T45 Coupling Sleeves.

Multiple Thread Sizes Available:Including various thread sizes like T45, ensuring compatibility with a range of drilling equipment. The meticulous design of T45 Coupling Sleeves meets the diverse needs of the construction industry.

Coupling Type |

| R:R25,R28,R32,R38

|

| T:T38,T45,T51 |

Applications:

Mining Projects: T45 Coupling Sleeves are an indispensable component in mining activities, ensuring precise and reliable drilling in various mining environments.

Tunnel Engineering: In tunnel construction, where accuracy is paramount, T45 Coupling Sleeves provide the stability and precision required for successful drilling.

Underground Excavation: T45 Coupling Sleeves excel in the challenges of underground excavation, contributing to efficient and dependable drilling operations.

Rock Drilling: For rock drilling applications, T45 Coupling Sleeves offer the durability and precision needed to tackle hard and abrasive materials.

Hydropower Projects: Contributing to the development of hydropower infrastructure, T45 Coupling Sleeves ensure precise drilling in the construction of water-related projects.

Ore Exploration: In the exploration of ore deposits, T45 Coupling Sleeves play a crucial role in achieving accurate and reliable drilling results.

Construction Projects: Beyond specialized fields, T45 Coupling Sleeves find applications in a wide range of construction projects, providing versatility and high performance.

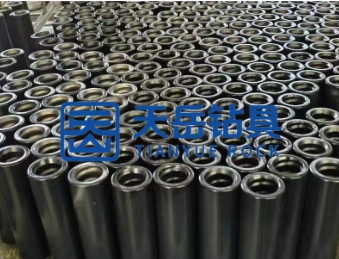

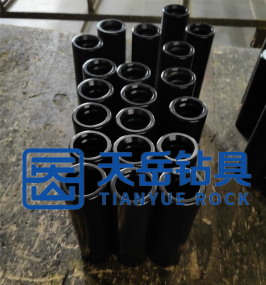

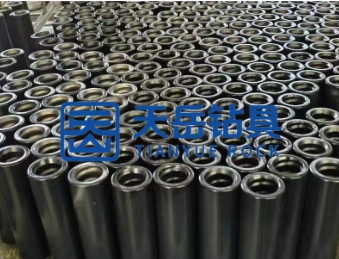

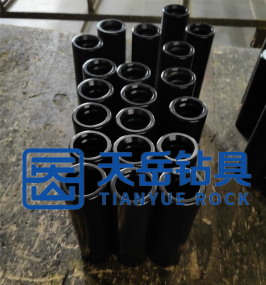

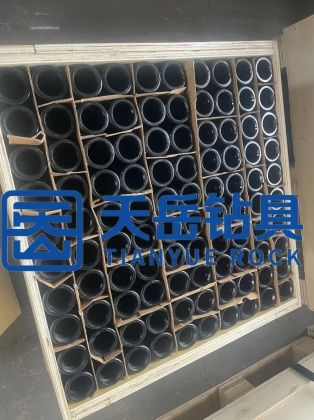

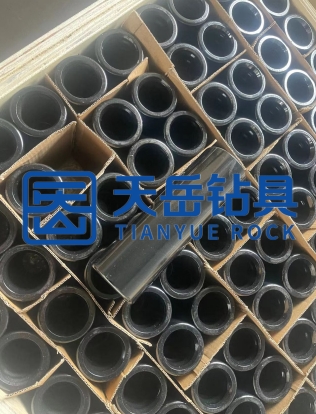

Actual pictures of drill rods |

| R25,R28,R32,R38 |

| T38,T45,T51 |

Choose T38 Coupling Sleeves for a drilling experience that prioritizes precision, durability, and versatility. Our product is meticulously designed to withstand the rigors of professional construction projects, ensuring your operations maintain peak efficiency throughout.

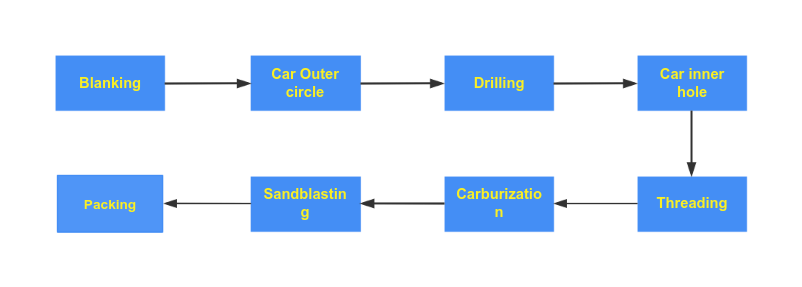

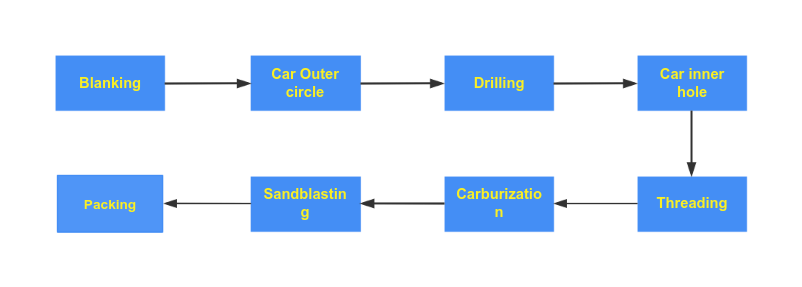

Rod Process Flow

About us

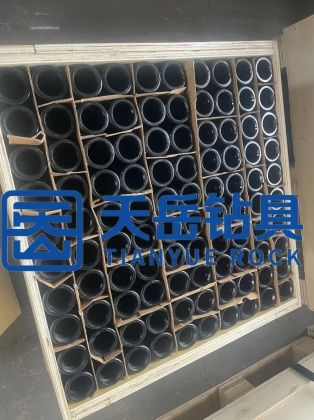

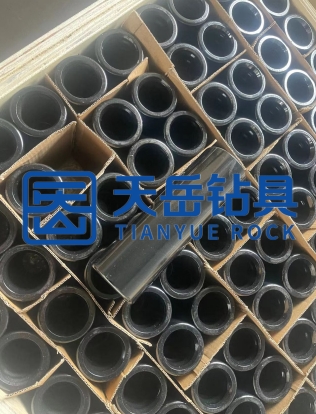

Packing

FAQ

Q1: Are you a manufacturer or a trade company?

A: We are a professional manufacturer of rock drilling tools. Our products include Top Hammer

Drill rods, Drill bits, Taper button bits and taper rods, DTH Bits and DTH rods, etc.

Q2: How can I get after-sales services?

A: Free replacements will be provided once the problems are caused by our product quality.

Q3: How is your quality control?

A: We have our own experienced QC team. There will be strict inspections for every order before

shipping out.

Q4. How can we trust your company?

We support Alibaba trade insurance. Protecting products quality, shipment on time and your

covered amount.We are alibaba trade assurance gold supplier and have more than 10 years

manufacturing experience of drill rods.

Q5. Quality control:

Each production process have quality inspector to check the quality . And we have a very strict

factory standard. There will also be strict inspection and testing for every order before shipping out.

Choose Coupling Sleeves for matchless reliability and enduring longevity. Our steadfast commitment is dedicated to delivering unprecedented products and services, guaranteeing unwavering efficiency and dependability for your mechanical equipment. Rely on our singular promise to provide enduring solutions, ensuring optimal performance remains at its zenith throughout every facet of your operations.