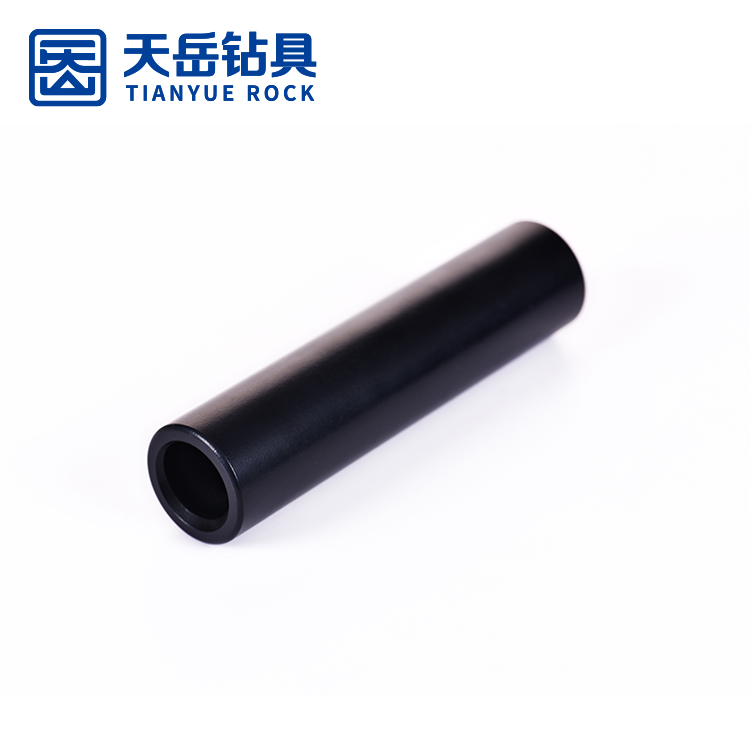

Elevate Precision Drilling with T38 Coupling Sleeves: A Professional's Choice

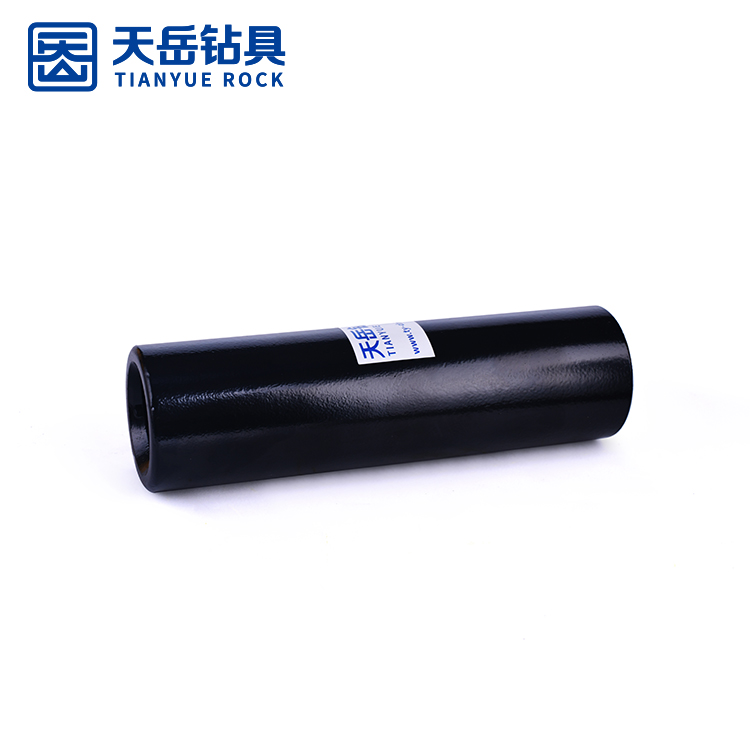

Unlock the pinnacle of precision and reliability in your drilling operations with our specialized T51 Coupling Sleeves. Crafted for excellence, these coupling sleeves stand as a testament to cutting-edge engineering, ensuring seamless connections between drill rods and shank adapters. Catering to the exacting demands of professionals, our T38 Coupling Sleeves redefine efficiency in a multitude of construction applications.

Product | Coupling Sleeves |

Other Names | Coupling sleeves,Drill bit adapter,Rock drill tools,Tophammer drill tools,Drifter drill tools,Coupling,Drill rod couplings,Drill coupling sleeves |

Material | 23CrNi3Mo |

Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

Thread | R25, R32, R35, R38, T38, T45, T51 |

Coupling Type | Full bridge coupling sleeve

Reducing coupling sleeve(Ctossover couplings,Adapter couplings,Reduction couplings,Reducer coupling)

Standard couplings(Semi bridge couplings) |

Length | 150mm~235mm |

Diameter | 33mm~72mm |

Custom Design | Size,Color,Diameter,Thread,Length |

| Coupling | Length | Diameter | Thread | Weight

approx

kg | TIANYUE P/N |

| mm | inch | mm | inch |

Coupling sleeves Coupling sleeves | 225 | 8 7/8 | 71 | 2 51/64 | T51 | 4.6 | 31-T51-71-225-23 |

| 225 | 8 7/8 | 76 | 3 | T51 | 4.8 | 31-T51-76-225-23 |

| 235 | 9 1/4 | 72 | 2 7/8 | T51 | 4.7 | 31-T51-72-235-23 |

| 235 | 9 1/4 | 77 | 3 1/32 | T51 | 4.9 | 31-T51-77-235-23 |

Features and Benefits:

Precision Engineering for Seamless Connectivity:Experience precision at its finest with the intricately designed internal threads of our T51 Coupling Sleeves. These sleeves ensure a flawless and secure connection between drill rods and shank adapters, setting the stage for unparalleled drilling accuracy.

Robust Construction for Enduring Performance:Built with durability as a cornerstone, our T51 Coupling Sleeves are engineered to endure the toughest challenges of construction applications. Professionals rely on the robust construction to deliver lasting performance under demanding conditions.

Versatility Across Demanding Applications:Tailored for a spectrum of construction projects including open pit mining, underground mining, tunnel engineering, and more, T51 Coupling Sleeves offer the adaptability needed to excel in diverse drilling environments.

Full Bridge Stability for Open-Air Excellence:The full bridge design ensures stability, making T51 Coupling Sleeves particularly advantageous for open-air construction. Enjoy a secure connection, straightforward disassembly, and minimal operational risks, guaranteeing a smooth and safe drilling experience.

Enhanced Flexibility with Different Threads:Opt for our reducing coupling sleeves with varied threads at the ends, allowing seamless connections with compatible products under specific conditions. This design enhances the overall versatility of T51 Coupling Sleeves.

Diverse Thread Size Options:Choose from a range of thread sizes, including T51, ensuring compatibility with an array of drilling equipment. Our T51 Coupling Sleeves are engineered with precision to meet the diverse requirements of the construction industry.

Coupling Type |

| R:R25,R28,R32,R38

|

| T:T38,T45,T51 |

Applications:

Open Pit Mining

Underground Mining

Tunnel Engineering

Roadway Excavation

Anchoring Engineering

Quarrying

And More

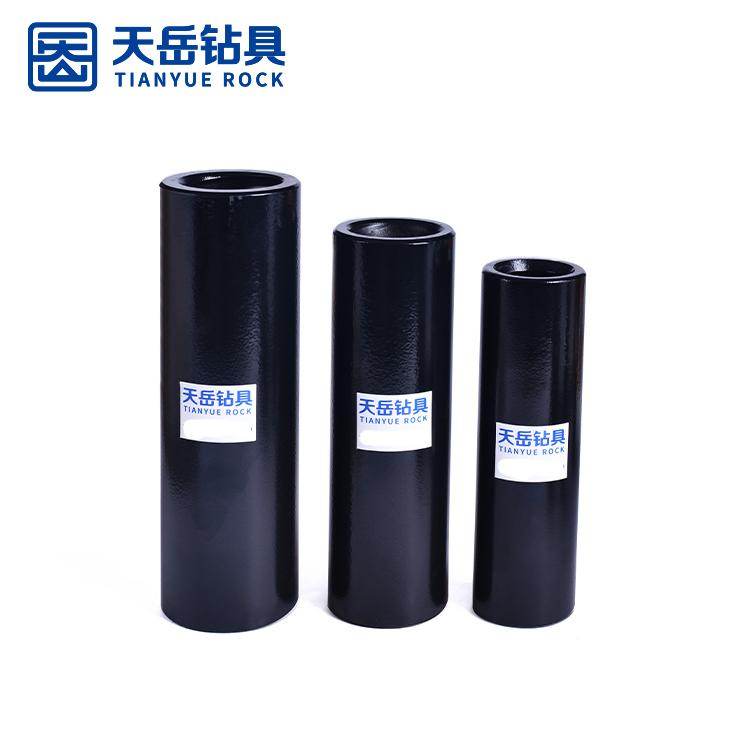

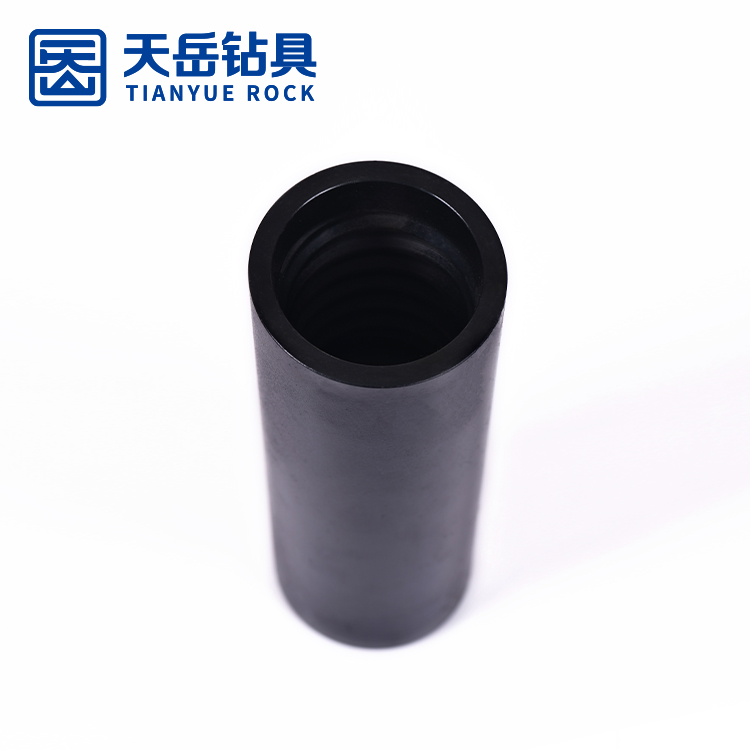

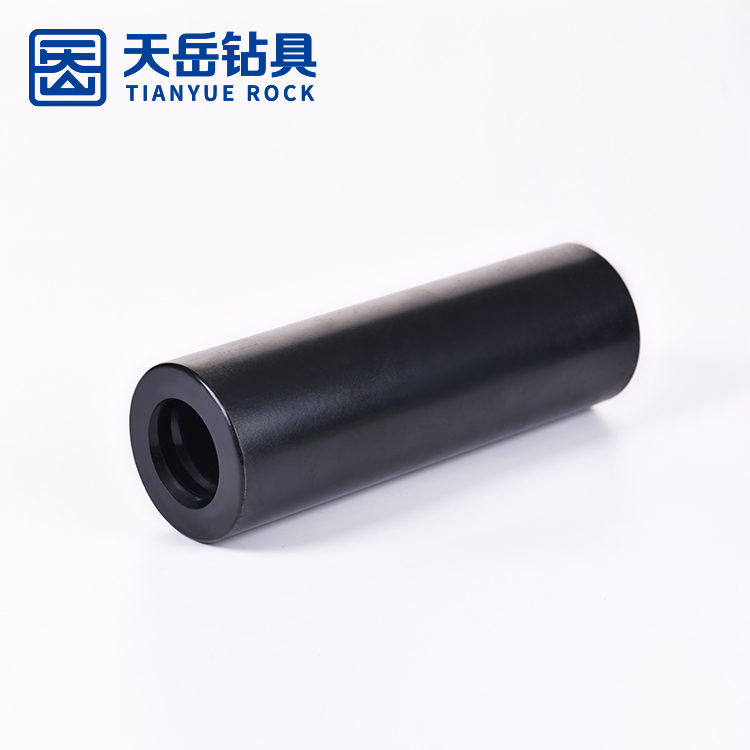

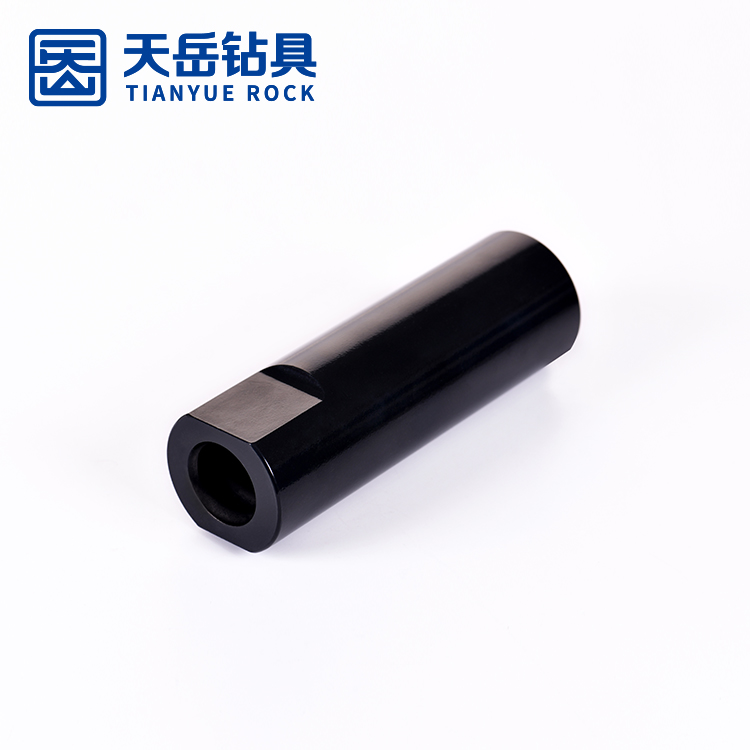

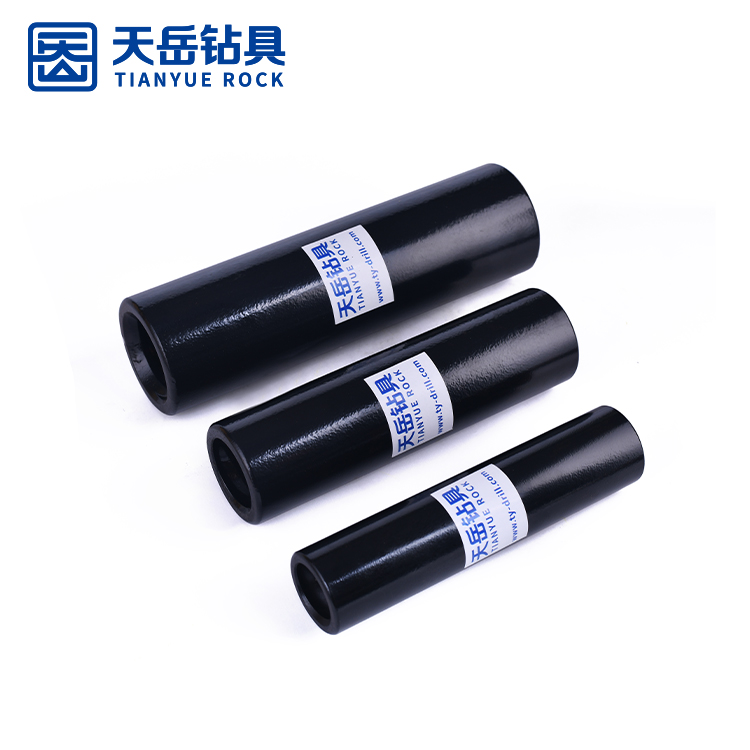

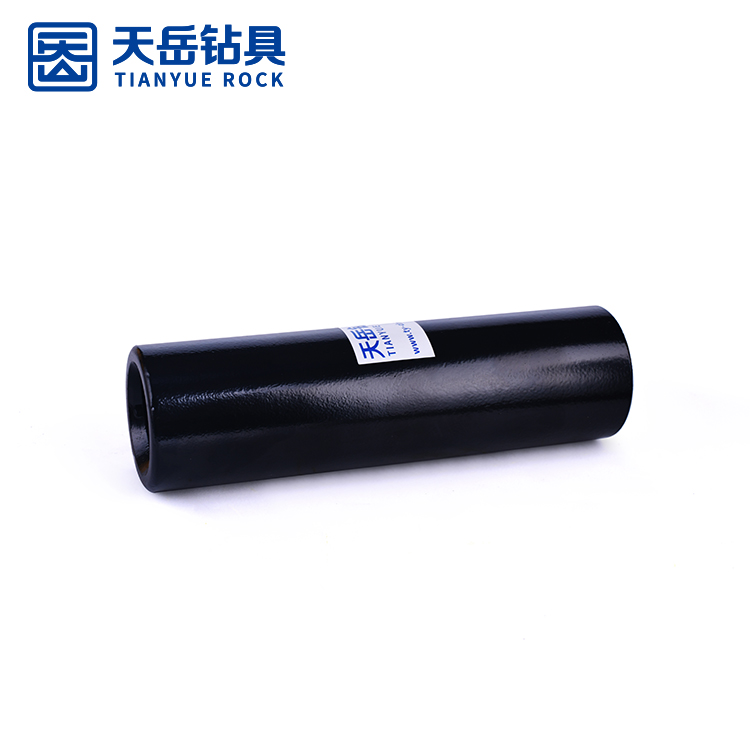

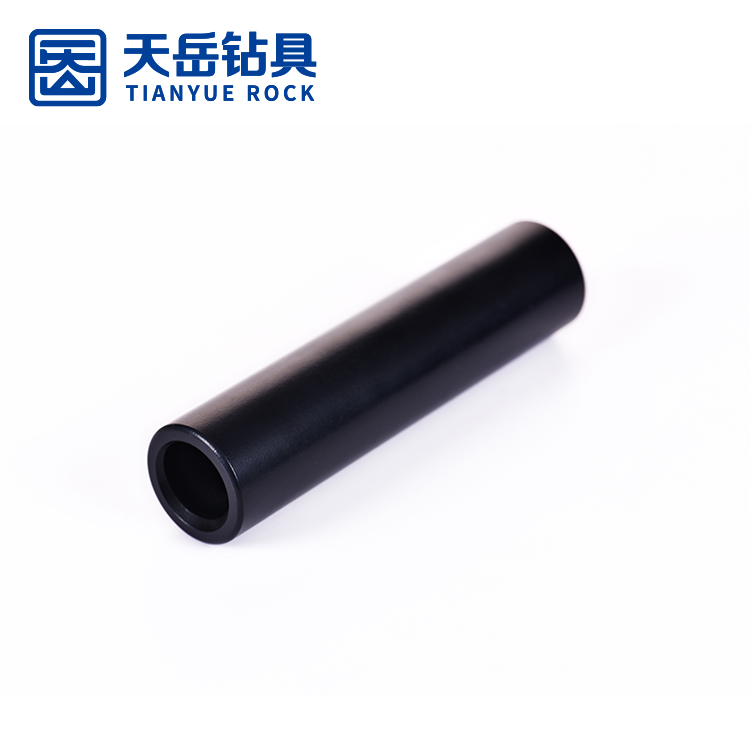

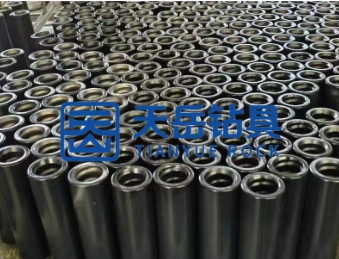

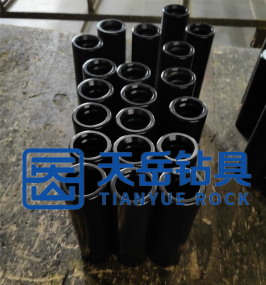

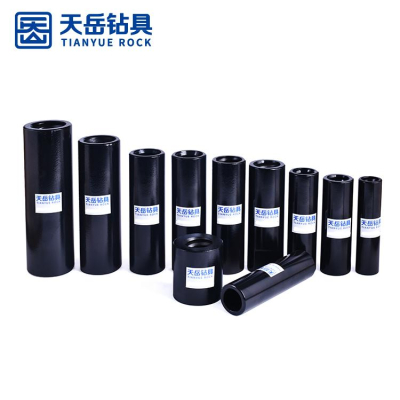

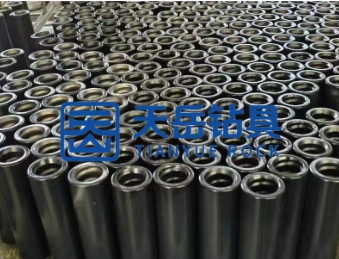

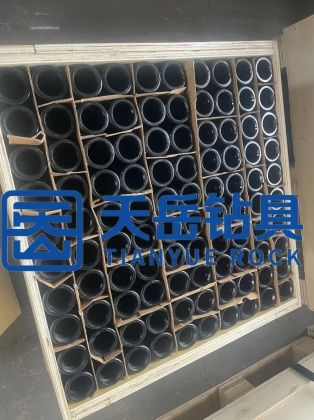

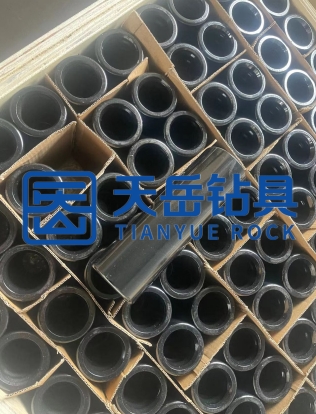

Actual pictures of coupling sleeves |

| R25,R28,R32,R38 |

| T38,T45,T51 |

Choose T51 Coupling Sleeves for a drilling experience that prioritizes precision, durability, and versatility. Our product is meticulously designed to withstand the rigors of professional construction projects, ensuring your operations maintain peak efficiency throughout.

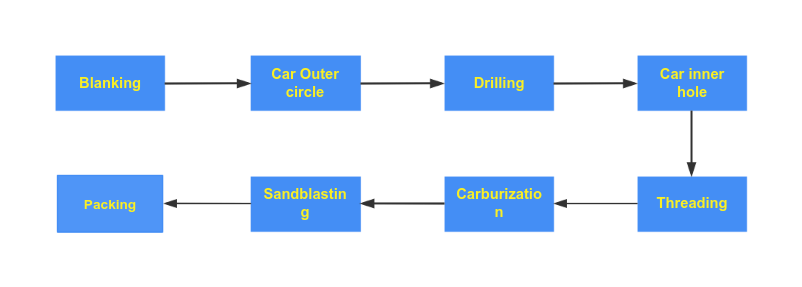

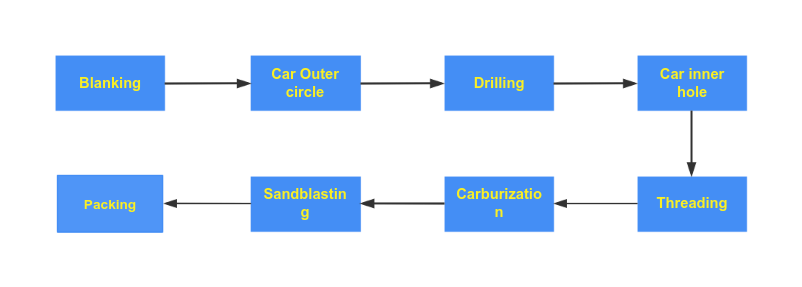

Coupling Sleeves Process Flow

About us

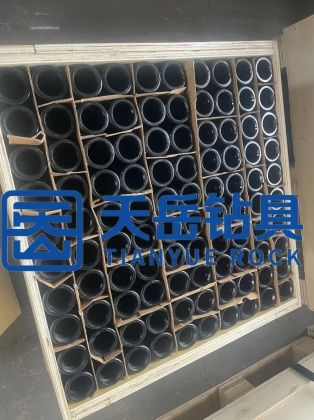

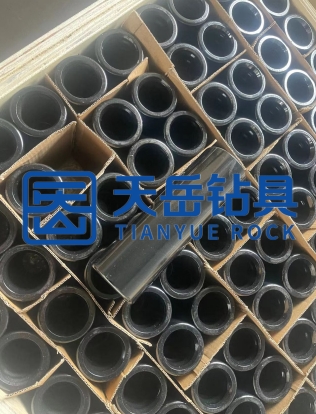

Packing

FAQ

Q1: Are you a manufacturer or a trade company?

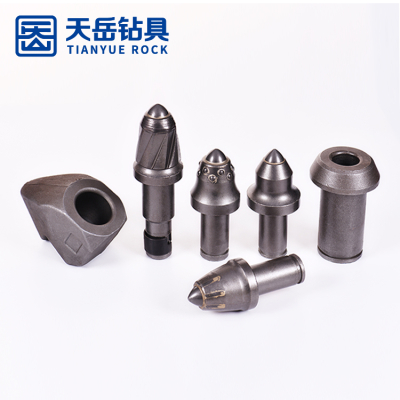

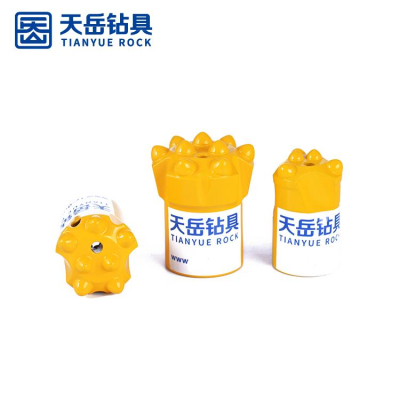

A: We are a professional manufacturer of rock drilling tools. Our product range includes Top Hammer Drill rods, Drill bits, Taper button bits and taper rods, DTH Bits and DTH rods, etc.

Q2: How can I get after-sales services?

A: We provide free replacements for products that have quality issues. Simply contact our customer service team and they will assist you with any after-sales needs.

Q3: How is your quality control?

A: We have a dedicated and experienced QC team in place. They conduct strict inspections at every stage of the manufacturing process to ensure the highest quality standards are maintained. Before shipping out, each order undergoes thorough inspection to guarantee its quality.

Opt for Coupling Sleeves for unparalleled reliability and extended longevity. Our unwavering commitment is to deliver exceptional products and services, ensuring the consistent efficiency and dependability of your mechanical equipment. Count on us to provide enduring solutions that maintain peak performance throughout your operations.