Sizes and Variations:

Rock tools come in various sizes to accommodate different drilling requirements. The selection of the appropriate size depends on factors such as the desired hole diameter and the specific geological conditions of the drilling site.

Applications:

Rock tools for furnace cross bits may find applications in drilling holes for various purposes related to furnace construction, maintenance, or specific industrial processes. This can include drilling for anchor holes, blast holes, or exploration purposes.

Product | Button Bits |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

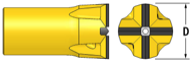

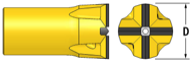

| Cross bit | Diameter | Top size(mm) | Thread | Weight

approx kg | TIANYUE P/N |

| mm | inch | H*W |

| 45 | 1 3/4 | 7*8 | R32 | 0.5 | 1222-45R32-7/8-40-24 |

| 50 | 1 31/32 | 7*8 | R32 | 0.6 | 1222-50R32-7/8-40-24 |

| 55 | 2 1/8 | 7*8 | R32 | 0.6 | 1222-55R32-7/8-40-24 |

| 55 | 2 1/8 | 7*8 | R38 | 0.7 | 1222-55R38-7/8-40-24 |

| 55 | 2 1/8 | 7*8 | T38 | 1.0 | 1222-55T38-7/8-40-24 |

| 60 | 2 3/8 | 7*8 | R32 | 0.7 | 1222-60R32-7/8-40-24 |

| 60 | 2 3/8 | 7*8 | R38 | 1.2 | 1222-60R38-7/8-40-24 |

| 60 | 2 3/8 | 7*8 | T38 | 1.3 | 1222-60T38-7/8-40-24 |

| 65 | 2 1/2 | 7*8 | R32 | 0.9 | 1222-65R32-7/8-40-24 |

| 65 | 2 1/2 | 7*8 | R38 | 1.3 | 1222-65R38-7/8-40-24 |

| 65 | 2 1/2 | 7*8 | T38 | 1.4 | 1222-65T38-7/8-40-24 |

| 70 | 2 3/4 | 7*8 | R32 | 1.3 | 1222-70R32-7/8-40-24 |

| 70 | 2 3/4 | 7*8 | T38 | 1.5 | 1222-70T38-7/8-40-24 |

| 80 | 3 1/8 | 7*8 | R32 | 1.7 | 1222-80R32-7/8-40-24 |

| 100 | 3 3/4 | 7*8 | R32 | 1.8 | 1222-100R32-7/8-40-24 |

| Face Design | Application |

|

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

|

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

|

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

|

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

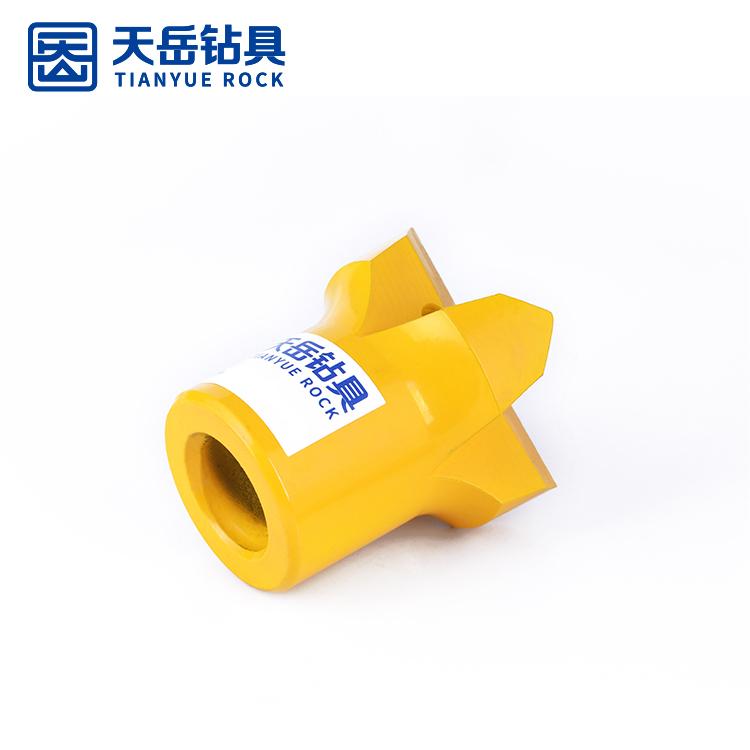

Cross bits are a type of drill bit commonly used in rock drilling applications. The term "cross bit" refers to the design of the cutting structure, which features multiple cutting edges arranged in a cross-shaped pattern. These bits are widely used in various industries, including mining, construction, and exploration drilling. Here are key features and information about cross bits:

Design:

Cutting Inserts:

Thread Types:

Applications:

Cross bits find applications in a range of drilling tasks, including blast hole drilling, exploration drilling, and production drilling. They are suitable for use in various rock formations, from softer to harder rocks.

Sizes and Variations:

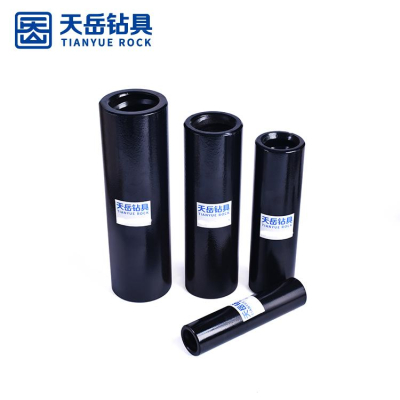

Compatibility:

Thread Lubrication:

Maintenance:

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

Thread Lubrication:

Some rock tools, especially those with threaded connections, may feature thread lubrication to reduce friction during the drilling process. Lubrication helps prevent thread wear and ensures the smooth rotation of the tool.

Compatibility:

It's important to note that the specific rock tools needed for furnace-related drilling applications can vary based on the unique requirements of the task at hand.

Cross bits are versatile tools widely used in rock drilling operations due to their effective cutting design. Proper selection, usage, and maintenance are essential to ensuring the success of drilling operations in industries such as mining, construction, and exploration.