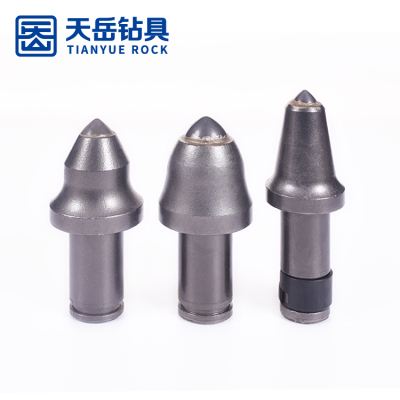

Use material:

Carbide head: High-end tungsten-cobalt alloy

Wear-resistant layer: Cemented carbide metallurgical composite material

Solder flux: Copper-based solder and flux

Tooth body: High-quality 42CrMo alloy steel

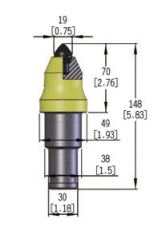

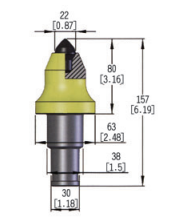

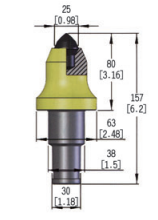

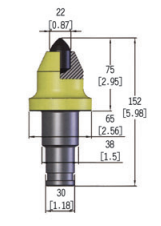

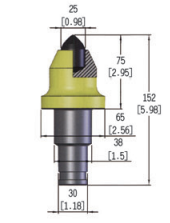

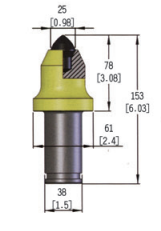

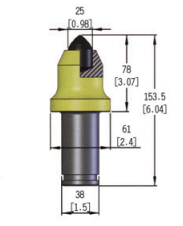

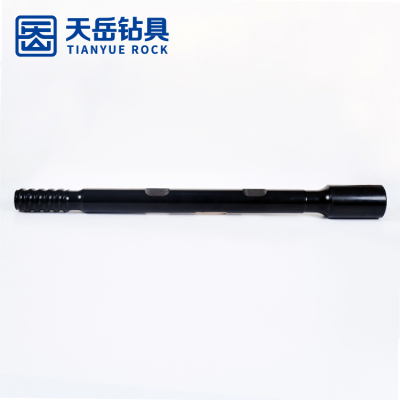

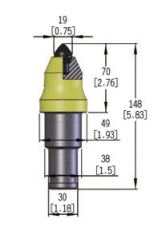

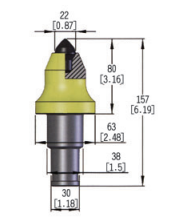

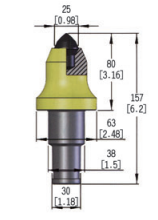

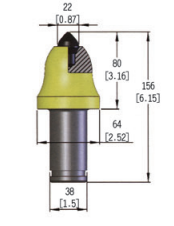

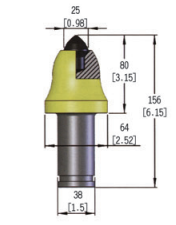

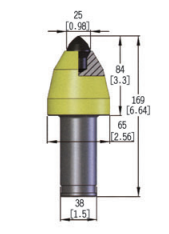

| 38mm/30mm(1.50'' /1.18'' ) step shank |

| JZ70/38-U47/M19-42-3 | JZ80/38-U47/M22-42-3 | JZ80/38-U47/M25-42-3 | JZ68/38-U47/M25-42-3 |

|  |  |  |

| JZ75/38-S160/Z22-42-3 | JZ75/38-S160/Z25-42-3 |

|

|

|  |

|

|

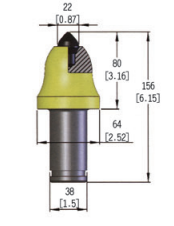

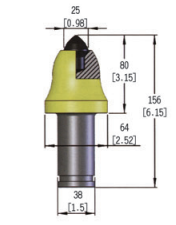

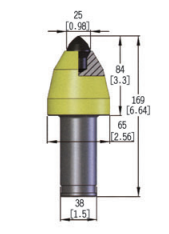

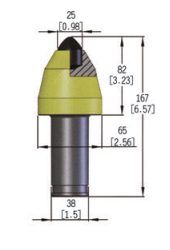

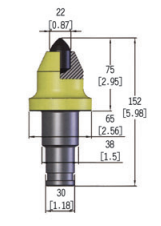

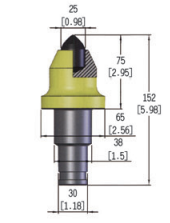

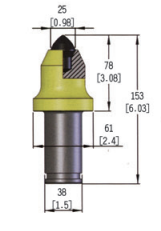

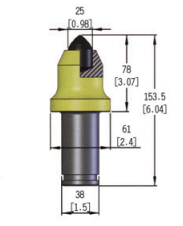

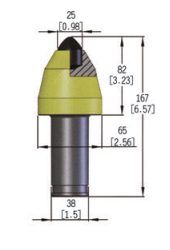

| 38mm(1.5'') shank |

| JZ80/38-U135/M22-42-3 | JZ80/38-U135/M25-42-3 | JZ78/38-S150/M25-42-3 | JZ78/38-S150/Z25-42-3 |

|  |  |  |

| JZ84/38-JMS260/Z25-42-3 | JZ82/38-JMS260/Z25-42-3 |

|

|

|  |

|

|

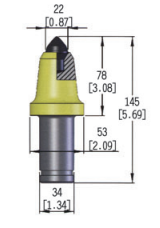

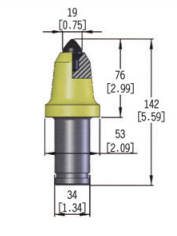

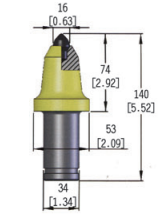

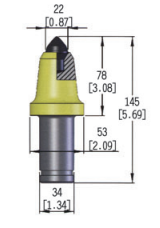

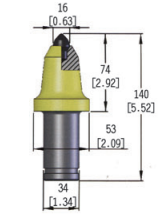

| 34mm(1.34'') shank |

| JZ78/34-S100/M22-42-3 | JZ76/34-S100/M19-42-3 | JZ74/34-S100/M16-42-3 |

|

|  |  |

|

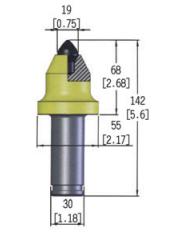

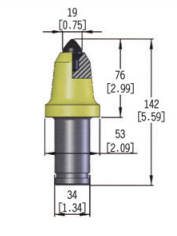

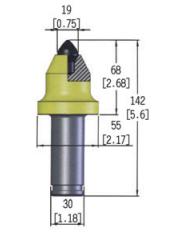

| 30mm(1.18'') shank |

| JZ68/30-U120/M19-42-3 | JZ68/30-U120/M22-42-3 |

|

|

|  |

|

|

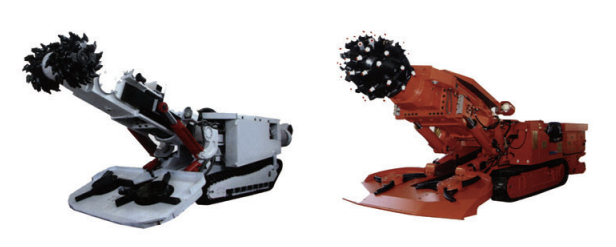

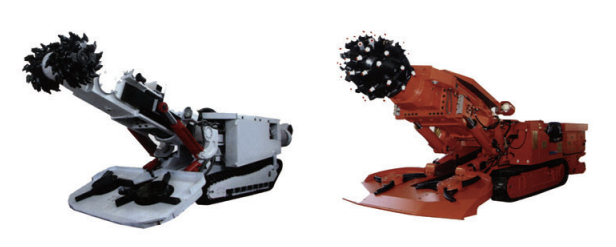

Crusher pick tools, also known as crusher picks or crusher hammer tips, are wear-resistant tools designed for use in crushing or breaking rock, ore, and other materials. These tools are commonly used in mining, construction, and excavation applications where the breaking or crushing of hard materials is required. Here are some key features and information about crusher pick tools:

Design:

Crusher pick tools are typically designed with a carbide tip or insert that provides hardness and wear resistance. The tip is attached to a steel body, forming a durable and effective tool for breaking or crushing applications.

Material:

The carbide tips of crusher pick tools are often made from tungsten carbide, a hard and tough material that can withstand the high impact and abrasion encountered during crushing operations.

Applications:

Mining: Breaking oversized rocks or ore during the mining process.

Construction: Breaking concrete, asphalt, or other hard materials.

Excavation: Breaking through hard soil, rock, or other materials during excavation projects.

Crusher pick tools are used in various applications, including:

Types of Crusher Picks:

Flat Pick: A straight, flat-tipped tool for general-purpose breaking.

Chisel Pick: A chisel-shaped tool for precision breaking or cutting.

Blunt Pick: A tool with a blunt tip for breaking through softer materials.

Moil Point: A pointed tool for concentrated breaking.

Crusher picks come in various types to suit different applications:

Mounting:

Crusher pick tools can be mounted on various types of equipment, such as hydraulic breakers, crushers, or excavator attachments. The mounting method depends on the specific equipment and application requirements.

Sizes:

Crusher pick tools come in different sizes to accommodate various crushing needs. The size of the tool is often selected based on the hardness and size of the material being crushed.

Durability:

The durability of crusher pick tools is crucial for their performance in demanding applications. Tungsten carbide tips provide the necessary hardness to withstand the high forces and abrasion encountered during crushing.

Maintenance:

Regular inspection and maintenance of crusher pick tools are essential for optimal performance. Checking for wear and replacing worn tips contribute to the longevity of the tools.

Safety Considerations:

Safety is a paramount concern when using crusher pick tools. Proper training, adherence to safety protocols, and the use of appropriate personal protective equipment (PPE) are essential for the well-being of operators.

Crusher pick tools are indispensable in industries where breaking or crushing of hard materials is a common task. The proper selection, use, and maintenance of these tools contribute to the efficiency and safety of various construction and mining operations.

Crusher Pick Tools Application