Construction:

Drifter rods are typically made of high-quality alloy or tool steel to withstand the forces and stresses encountered during drilling. They are threaded on both ends to allow for the attachment of the drifter on one end and the drill bit on the other.

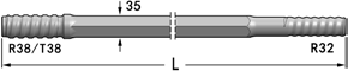

Product | Drill Rod |

Other Names | Drill rod,Drill pipe,Extension drill rod,Hollow bar,Top hammer drill rod,Excavation drill rod,Rock drill rod,Round drilling rod,Hex drill rod,Tomroc dill pipe,Rock drilling tools,Rock drill tools,Rock drilling tools,Threaded drill rod,Mining drill rod,Thread rock drill rod |

Material | 23CrNi3Mo |

Application | Bench Drilling, Production drilling, Long hole drilling, Drifting,Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting |

Thread | R22, R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35... |

Rod Type | Extension Rod,MF Rod,Speedrod,Drifter Rod,Guide Tube,Drill tube |

Boby Type | Round drill rod,Hexagonal drill rod |

Length | 260mm~6400mm |

Diameter | 20mm~87mm |

Custom Design | Size,Color |

Length and Diameter:

The length and diameter of drifter rods can vary depending on the specific drilling equipment and application. Longer rods may be used for deeper drilling, while the diameter is chosen based on the capacity and requirements of the drifter.

Drill rod | Length | Diameter | Weight

approx

kg | TIANYUE P/N |

| mm | Foot | mm | inch |

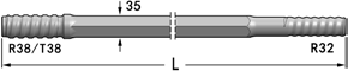

Drifter rod, R/T38-Hex32-R32

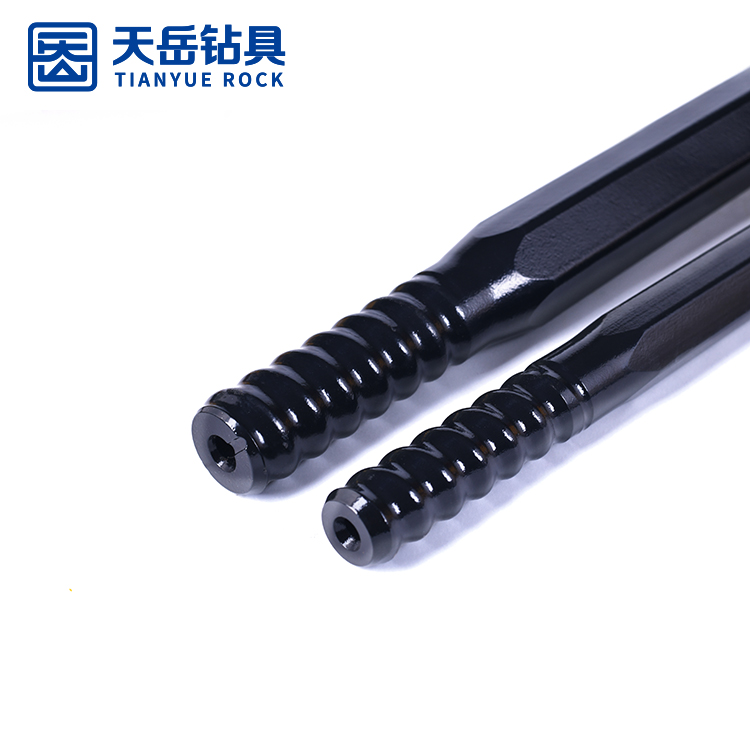

Flushing hole 9.6mm.

| 2400 | 7'10" | 32 | 1 1/4 | 15.3 | 22H32-R32/T38-2400-23 |

| 3090 | 10'11/2" | 32 | 1 1/4 | 19.8 | 22H32-R32/T38-3090-23 |

| 3400 | 11'13/4" | 32 | 1 1/4 | 21.7 | 22H32-R32/T38-3400-23 |

| 4000 | 13'13/8" | 32 | 1 1/4 | 25.5 | 22H32-R32/T38-4000-23 |

| 4310 | 14'11/2" | 32 | 1 1/4 | 27.5 | 22H32-R32/T38-4310-23 |

| 4920 | 16'11/2" | 32 | 1 1/4 | 31.3 | 22H32-R32/T38-4920-23 |

| 5530 | 18'11/2" | 32 | 1 1/4 | 35.2 | 22H32-R32/T38-5530-23 |

Drifter rod, R/T38-Hex35-R32

Flushing hole 9.5mm.

| 3090 | 10'11/2" | 35 | 1 3/8 | 24.0 | 22H35-R32/T38-3090-23 |

| 3700 | 12'11/2" | 35 | 1 3/8 | 28.7 | 22H35-R32/T38-3700-23 |

| 4000 | 13'13/8" | 35 | 1 3/8 | 31.1 | 22H35-R32/T38-4000-23 |

| 4310 | 14'11/2" | 35 | 1 3/8 | 33.4 | 22H35-R32/T38-4310-23 |

| 4920 | 16'11/2" | 35 | 1 3/8 | 37.8 | 22H35-R32/T38-4920-23 |

| 5530 | 18'11/2" | 35 | 1 3/8 | 42.9 | 22H35-R32/T38-5530-23 |

| 6100 | 20' | 35 | 1 3/8 | 47.3 | 22H35-R32/T38-6100-23 |

Compatibility:

Drifter rods are designed to be compatible with specific types and models of drifters. It's important to use the correct size and type of drifter rod for a particular drifter to ensure efficient and safe drilling operations.

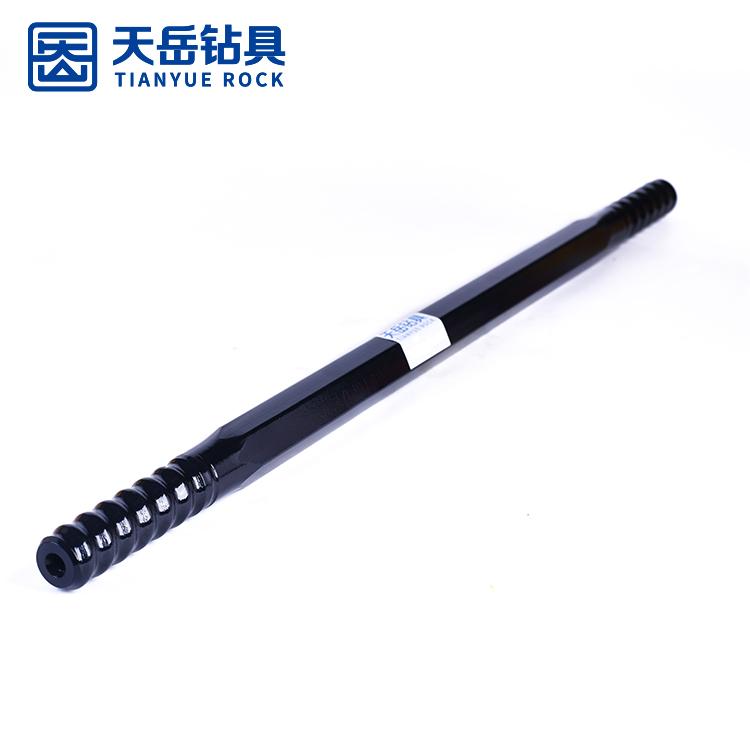

Rod Shape |

| R:Round

MF rod,Guide Tube,Extension Rod |

| H: Hex

Drifter Rod |

Maintenance:

Like any drilling tool, drifter rods require regular inspection and maintenance to ensure optimal performance and longevity. Wear and tear, as well as damage, should be addressed promptly to avoid equipment malfunction.

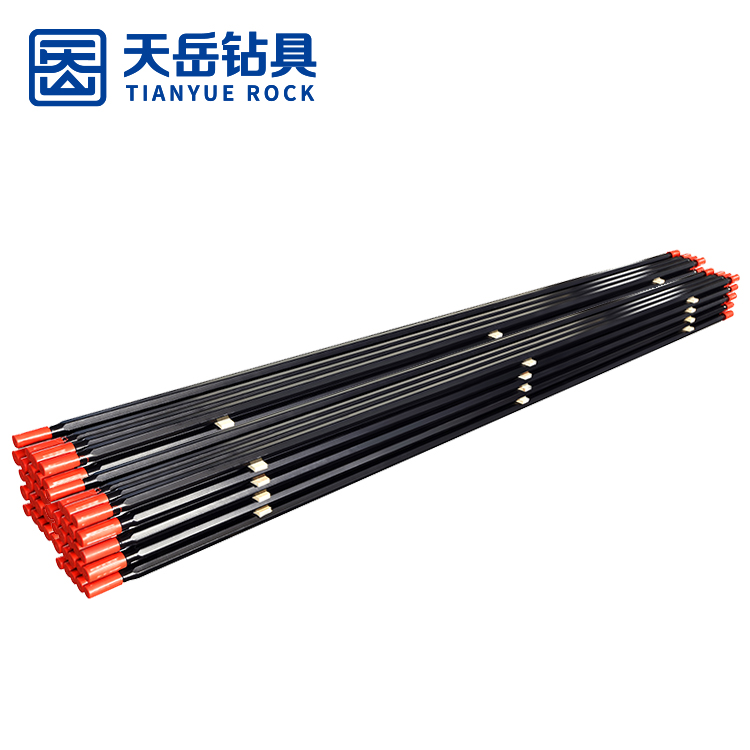

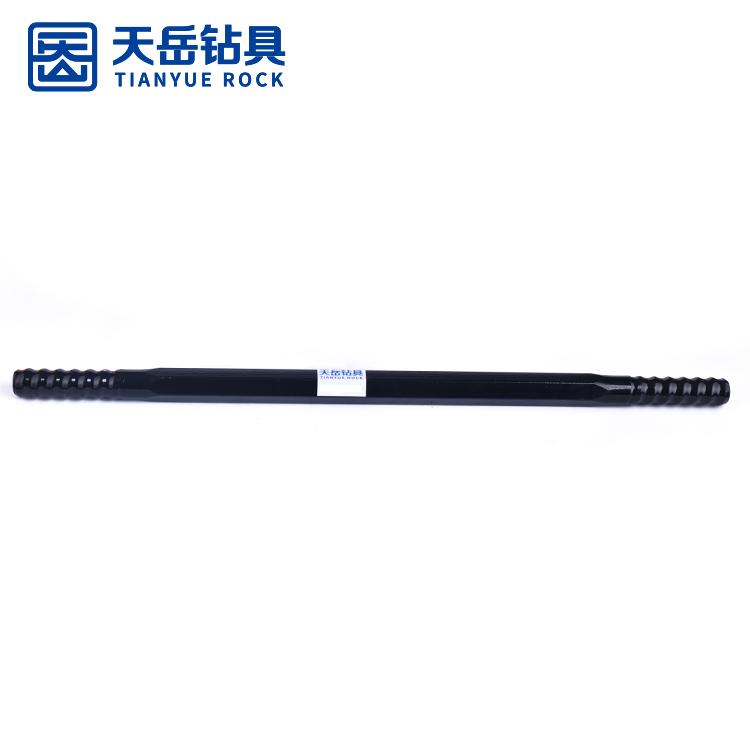

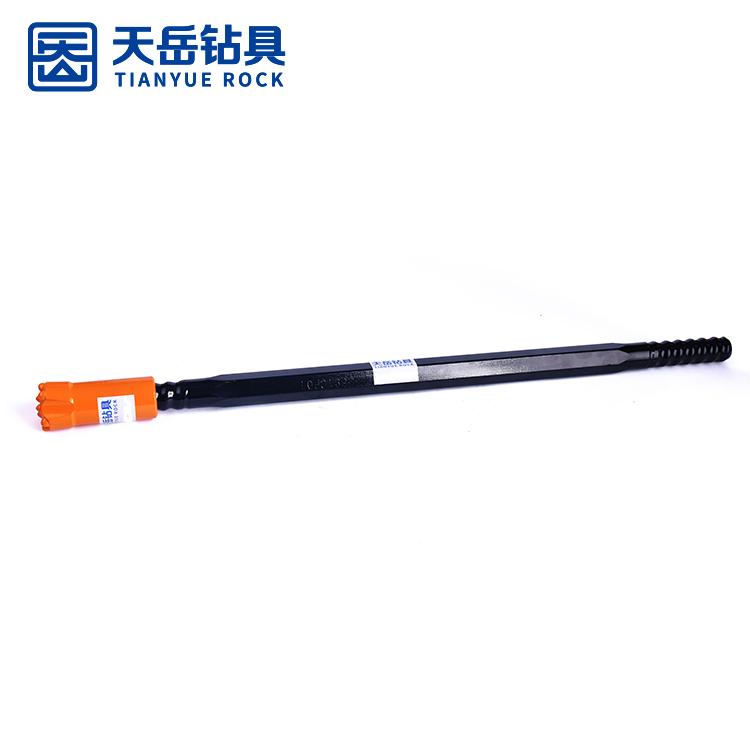

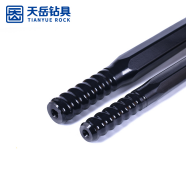

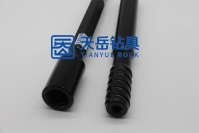

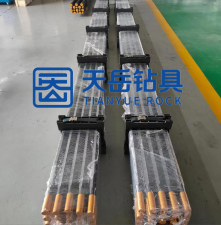

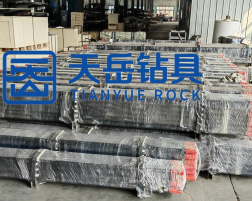

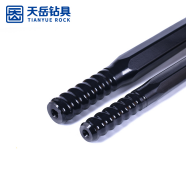

Actual pictures of drill rods |

| Extension Rod |

| Speed Rod |

|

Drifter Rod |

| Guide Tube |

Applications:

Drifter rods are commonly used in mining, quarrying, and construction industries where rock drilling is required. They are essential for creating holes for various purposes, such as blasting, anchor installation, or exploration.

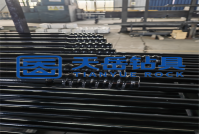

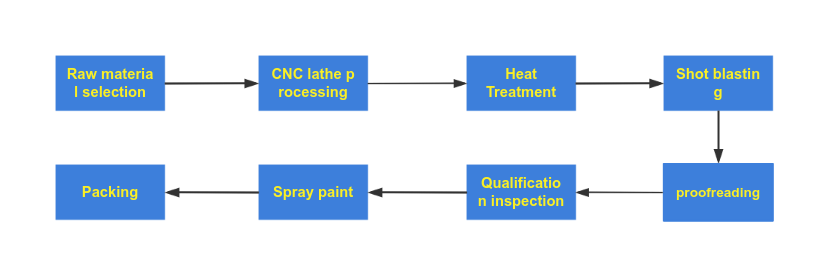

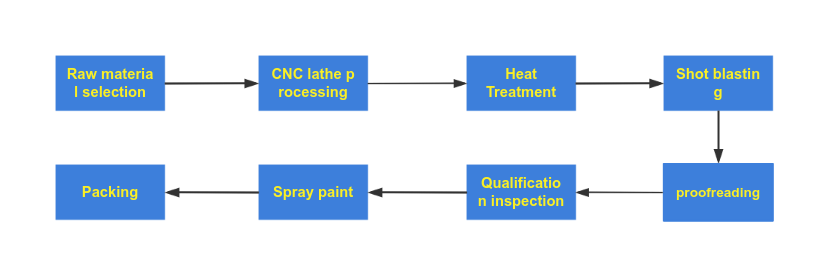

Rod process flow |

|

|

When using drifter rods, operators should follow manufacturer guidelines for proper usage, maintenance, and safety precautions to ensure the longevity and efficiency of the drilling equipment.

The specific length and diameter of an R32 drifter rod can vary based on the drilling equipment and application requirements. Different lengths may be used for varying drilling depths, and the diameter is chosen according to the capacity of the drilling system.

Like any drifter rod, proper usage and regular maintenance are essential to ensure optimal performance. This includes inspecting for wear, damage, and proper thread engagement. Following manufacturer guidelines for usage and maintenance is crucial for safety and efficiency.

FAQ |

Q1:Are you manufacturery or trade company?

A:We are manufacturer, has more than 20 years of professional production experience .Products including Drill Rod、 Drill Bit、Shank Adaptes、Coupling Sleeve、Drill small hole、Coal Mining Picks、Tapper Button Bit and Rod、 Integral Drill Rod etc.

Q2: Do you offer warranty on your products?

A: Yes. For different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The longest period of warranty is 12 months after shipping date.

Q3: How is your quality control?

A: We have our own experienced technology.There will be strict inspection and testing for every order before shipping out.

Q4: How long is your delivery time?

A: 1-3days for the products in stock; regular order delivery in 15-20days

Q5: After Services:

A: (1) Our sales team will response for your question within 24 hours (Holidays included).

(2) Technical Support will be available in any time.

(3)Free replacement will provide once the failure confirmed caused by our product quality.

Q6:Methods of Payment:

A:We offer different payment terms, including T/T, D/A, D/P, L/C and O/A, etc. You can choose your preferred payment methods before we shipping the goods.

|

R32 drifter rods are typically made of high-quality alloy or tool steel to withstand the mechanical stresses and impacts encountered during rock drilling. They are manufactured to meet industry standards for strength and durability.