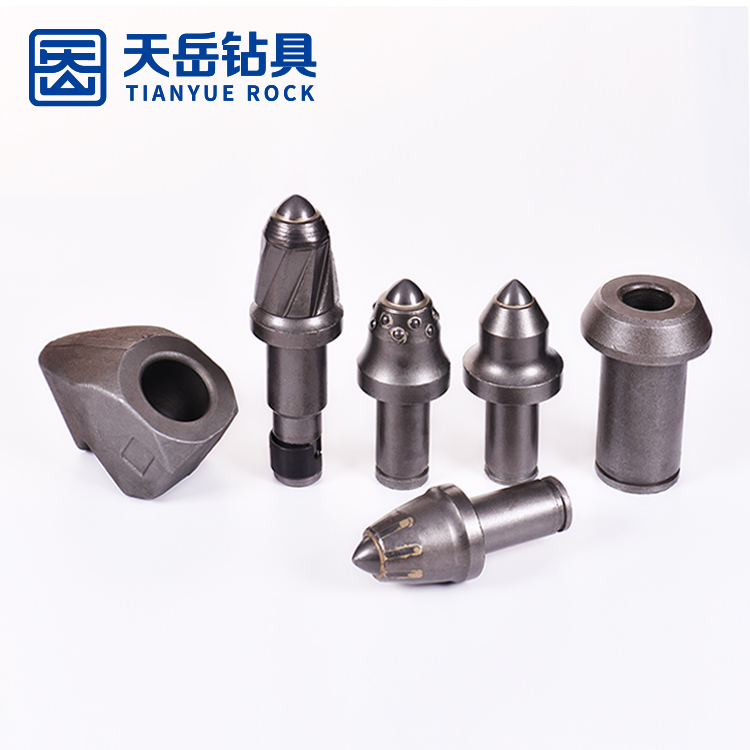

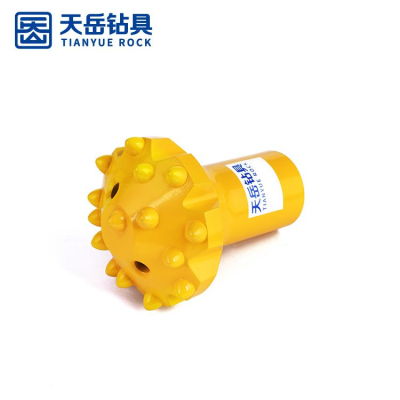

Material:

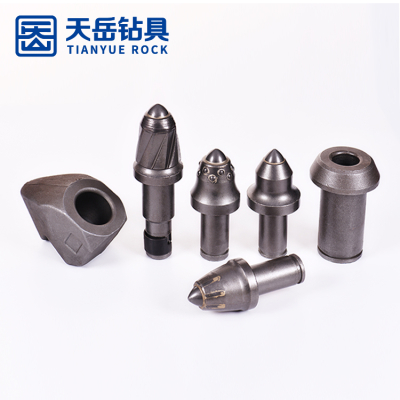

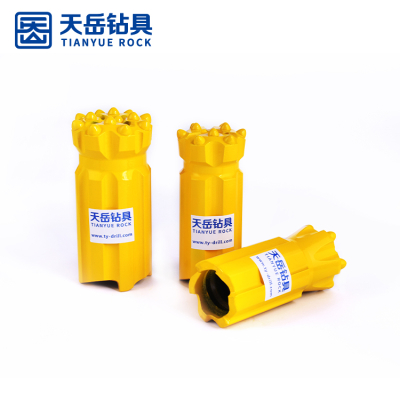

Conical pick sleeves are typically made from durable and wear-resistant materials, ensuring longevity and performance in challenging drilling or cutting environments. Common materials include high-strength steel.

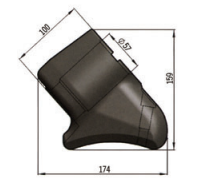

Compatibility:

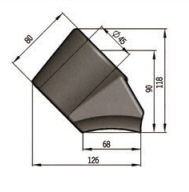

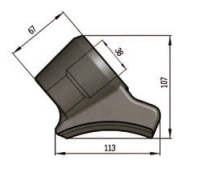

Conical pick sleeves are designed to be compatible with specific conical picks and drilling equipment. The dimensions and thread patterns are crucial for ensuring a proper fit and secure attachment.

Threaded Ends:

The sleeve often has threaded ends that match the threads on the conical pick and the drilling equipment. This threading ensures a tight and secure connection.

Ease of Replacement:

Conical pick sleeves are designed for ease of replacement. When the conical pick becomes worn or damaged, the sleeve allows for the straightforward replacement of the pick without the need for complex tools or procedures.

Durability:

Given the harsh conditions in which conical picks are used, the sleeve is constructed to withstand abrasion, impact, and other stresses encountered during drilling or cutting operations.

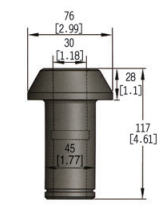

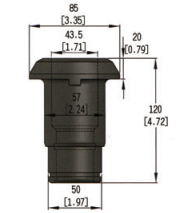

Variety of Sizes:

Conical pick sleeves are available in different sizes and specifications to match the requirements of various conical picks and drilling equipment. The choice of size depends on factors such as the diameter of the pick and the type of equipment being used.

Secure Connection:

The primary function of the conical pick sleeve is to provide a secure and reliable connection between the conical pick and the drilling or cutting equipment. This ensures the efficient transfer of forces and rotational motion during drilling.

Proper selection and maintenance of conical pick sleeves are essential for the overall performance and longevity of the cutting tools. Manufacturers typically provide specifications and guidelines for the correct use, replacement, and maintenance of conical pick sleeves to ensure optimal performance in specific applications.