Bulldozers:

Bulldozers are powerful machines with a broad blade at the front. They are used to push and remove overburden, creating access to the mineral deposit.

Shovels:

Power shovels are machines equipped with a bucket at the end of a boom. They are used for digging and loading materials, including overburden and ore.

Haul Trucks:

Haul trucks are large, heavy-duty trucks used to transport mined materials, such as ore or overburden, from the mining site to the processing or stockpile area.

Wheel Loaders:

Wheel loaders are versatile machines equipped with a front-mounted bucket. They are used for loading and transporting materials within the mining site.

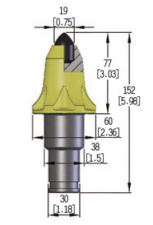

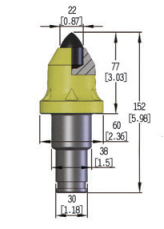

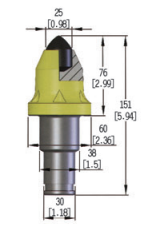

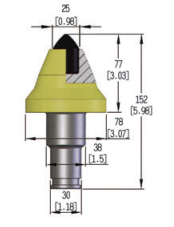

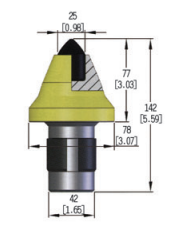

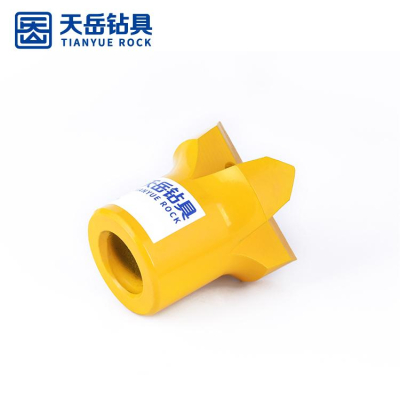

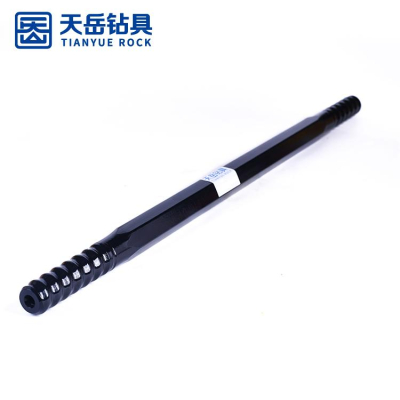

Drilling Equipment:

Drilling rigs are used to create holes for explosives or to sample the rock. Rotary drills, blasthole drills, and other drilling equipment are essential for preparing the rock for blasting and subsequent extraction.

Blasters:

Blasters are individuals or specialized equipment responsible for safely detonating explosives in the rock to break it apart, facilitating easier excavation.

Graders:

Graders are machines equipped with a long blade used for leveling and smoothing the surface after overburden removal or during road construction within the mining site.

Surface Miners:

Surface miners are machines designed to cut, crush, and load materials in a single pass. They are particularly useful for selective mining and minimizing waste.

Water Trucks:

Water trucks are used to suppress dust on the mining site, improving visibility and reducing potential health hazards.

Surveying and GPS Equipment:

Advanced surveying and GPS equipment are used for accurate mapping, surveying, and planning of surface mining activities.

The selection of surface mining tools depends on factors such as the type of mineral deposit, geology, production requirements, and environmental considerations. Safety measures are crucial in surface mining operations to protect workers and minimize environmental impacts.