Purpose:

Foundation drills are used to create deep holes in the ground for the installation of foundation elements. These elements provide structural support by transferring loads from a building or structure to the underlying soil or rock.

Types of Foundation Drills:

Crawler-Mounted Drill Rigs: Mounted on tracks for increased mobility and stability.

Truck-Mounted Drill Rigs: Mounted on trucks for easy transportation between job sites.

Pile Top Drills: Used for drilling from the top of piles or caissons.

There are several types of foundation drills, each designed for specific drilling conditions and foundation types. Common types include:

Drilling Methods:

Rotary Drilling: Uses a rotating drill bit to cut and crush the soil or rock.

Auger Drilling: Utilizes a rotating helical screw (auger) to remove soil or other materials.

Casing or Caisson Drilling: Involves drilling inside a temporary or permanent casing for added support.

Foundation drills can use various drilling methods, including:

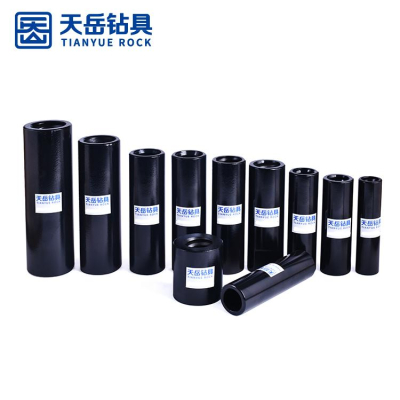

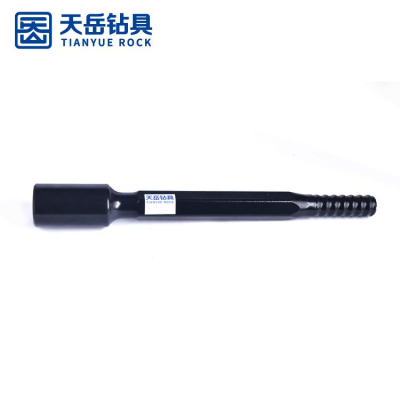

Drilling Tools:

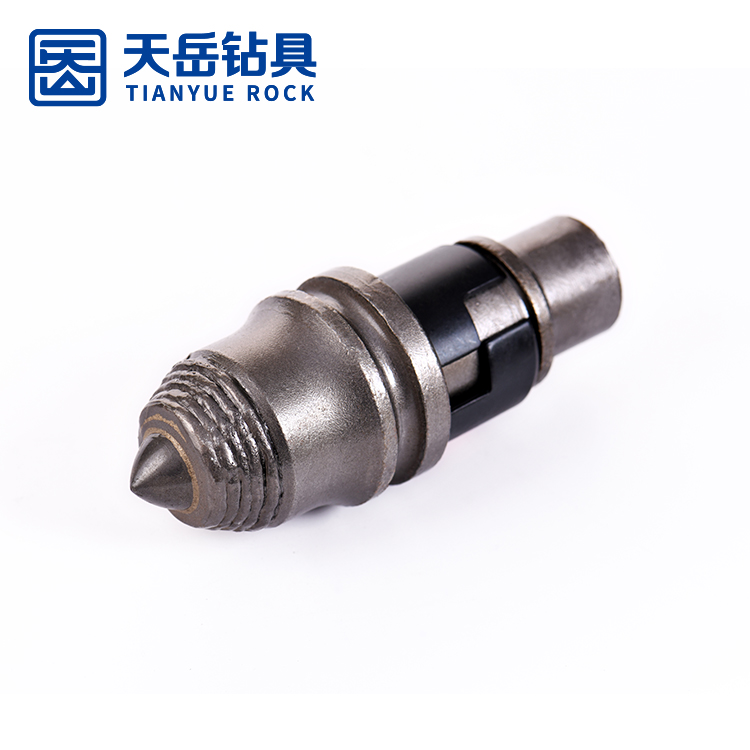

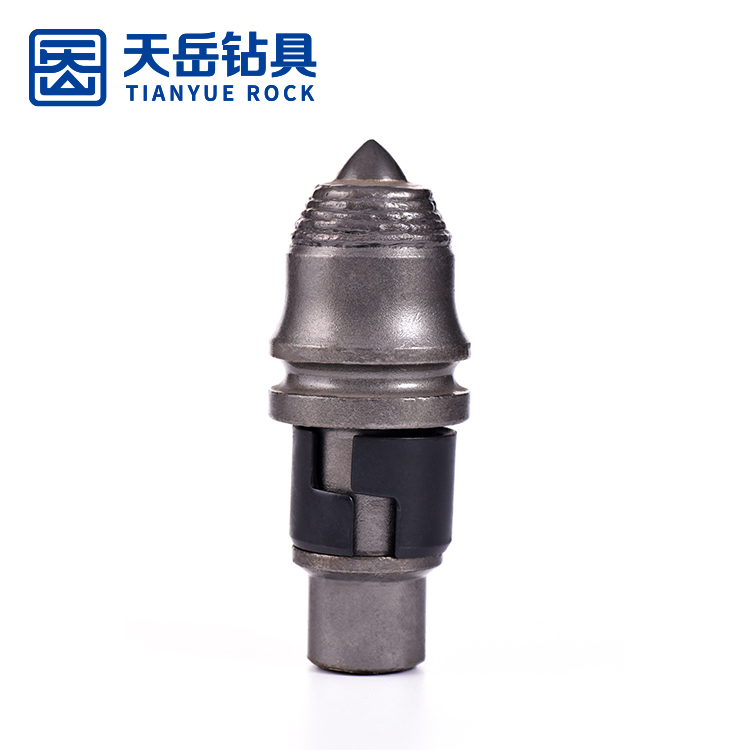

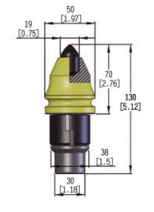

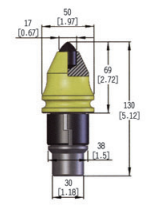

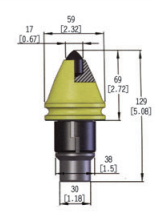

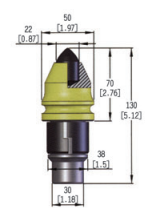

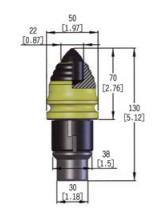

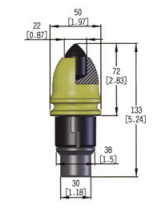

Drill Bits: Come in different designs and materials based on the type of soil or rock being drilled.

Augers: Used for drilling in softer soils or for creating boreholes for certain foundation types.

Foundation drills are equipped with various drilling tools, such as:

Depth and Diameter:

Foundation drills are capable of drilling to significant depths, depending on the specific model. The diameter of the drilled hole can also be adjusted based on the foundation requirements.

Mobility:

Foundation drills are designed for mobility, allowing them to move around construction sites and access various drilling locations. Crawler-mounted and truck-mounted drills offer different levels of mobility and flexibility.

Automation and Control Systems:

Modern foundation drills may feature advanced automation and control systems to enhance precision and efficiency in drilling operations. These systems can monitor drilling parameters and make real-time adjustments for optimal performance.

Safety Features:

Safety is a critical consideration in foundation drilling. Drill rigs are equipped with safety features to protect operators and ensure safe drilling practices.

Environmental Considerations:

Foundation drilling can generate drilling spoils and may have environmental considerations. Proper disposal or reuse of drilling spoils is important, and environmental regulations must be followed.

Foundation drills are integral to the construction industry, providing the means to create stable and load-bearing foundations for various structures. Their capabilities in drilling deep and precisely controlled holes make them essential in many construction projects.