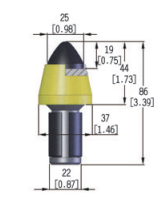

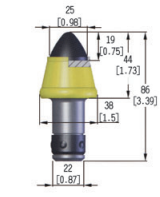

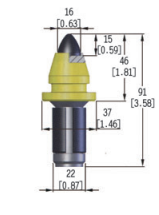

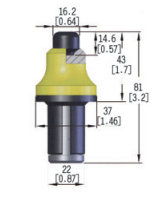

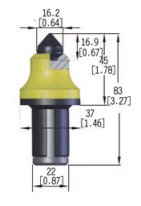

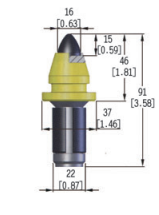

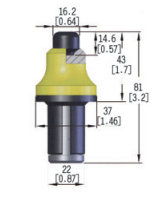

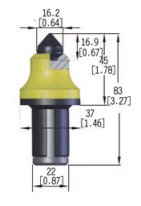

| 22mm(0.87'') step shank |

| JZ44/22-C858/P25-23-2 | JZ44/22-C87/P25-23-2 | JZ46/22-C387/P16-23-2 | JZ49/22-C87/P16-23-2 |

|  |  |  |

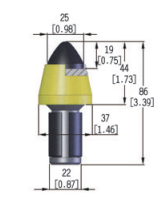

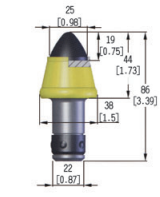

| JZ43/22-K1LW/C16Y-23-2 | JZ45/22-K1LW/C16-23-2 |

|

|

|  |

|

|

Grader blades are components used in grader machines, which are heavy equipment vehicles widely used in construction, road maintenance, and civil engineering projects. Graders, also known as motor graders or road graders, are equipped with a long blade that is adjustable and positioned between the front and rear axles. The grader blade plays a crucial role in leveling and shaping surfaces, such as roads and construction sites. Here are key features and information about grader blades:

Blade Types:

Straight Blades: Straight blades are used for basic leveling and cutting tasks.

Moldboard Blades: These have a curved shape, allowing for more efficient material displacement during grading.

Snow Blades: Designed for snow removal, these blades often have additional features to control and direct snow.

Grader blades come in various types, each designed for specific applications:

Material:

Grader blades are typically made from high-strength steel or wear-resistant materials to withstand the abrasion and impact encountered during grading operations.

Adjustability:

The grader blade is adjustable, allowing operators to control the angle, pitch, and height of the blade. This adjustability is crucial for achieving the desired grading outcome.

Blade Size:

Grader blades come in various sizes, and the selection depends on the specific grading requirements of the project. Larger blades are suitable for wide grading passes, while smaller blades offer precision.

Tilt and Rotation:

Some grader blades are equipped with tilt and rotation features, allowing the operator to tilt the blade to the left or right and rotate it for more versatile grading capabilities.

Cutting Edges:

Grader blades often have replaceable cutting edges made from materials like carbide or other wear-resistant alloys. These cutting edges can be rotated or replaced when worn to maintain optimal performance.

Ripper Attachment:

Some graders have a ripper attachment, which is a set of tines or teeth mounted behind the grader blade. The ripper is used to break up hard or compacted soil before the grading process.

Visibility:

The design of the grader often includes features to enhance visibility for the operator. This is crucial for precise grading and maneuvering.

Operator Controls:

Graders are operated by skilled operators who use a control console equipped with levers and buttons to manipulate the blade and control the machine's movements.

Grader blades are essential components in achieving smooth and precise grading in construction and road maintenance projects. The versatility and adjustability of grader blades make them valuable tools for shaping surfaces and ensuring proper drainage and slope control.

Grader Blades Tools Application