How to choose rock picks to improve production efficiency?

Correct selection of picks is critical to excavation efficiency. Here are some key considerations:

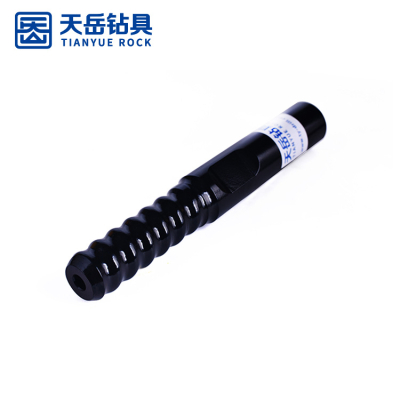

1. Mineral type and hardness: Different picks are suitable for underground minerals of different types and hardness. Make sure you choose a pick that matches the rock hardness.

2. Cutting efficiency: The design and shape of the pick will affect the cutting efficiency. Some picks are suitable for high-speed cutting, while others are suitable for harder rock.

3. Wear Resistance: Consider the wear resistance of the pick, as wear will reduce efficiency. Carbide is a commonly used wear-resistant pick material.

4. Maintenance and replacement: Regular maintenance and timely replacement of severely worn picks are key to improving efficiency. It is also important to clean and lubricate the cutting edge and cutterhead.