Productionprocesses: involving multiple processes, such as steel rolling, forging, normalizing,quenching and tempering,carbide welding,etc.

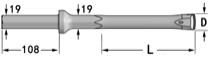

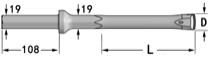

| Integral Drill Rod |

| Bit Diameter | 24mm~40mm |

| Rod Diameter | Hex19, Hex22 |

| Shank Length | 108mm |

| Effective Length | 400mm~6400mm |

| Integral drill steels | Length | Bit dia. | Weight

approx

kg | TIANYUE P/N |

| mm | foot |

Chisel bit integral

Shank 19mm×108mm

| 400 | 1'4" | 29 | 1.3 | 5H19-291508-0400-40-2 |

| 500 | 1'8" | 29 | 1.5 | 5H19-291508-0500-40-2 |

| 800 | 2'7" | 28 | 2.2 | 5H19-281508-0800-40-2 |

| 1000 | 3'33/8" | 28 | 2.6 | 5H19-281508-1000-40-2 |

| 1200 | 3'11" | 27 | 3 | 5H19-271508-1200-40-2 |

| 1600 | 5'3" | 27 | 3.9 | 5H19-271508-1600-40-2 |

| 2400 | 7'10" | 26 | 5.7 | 5H19-261508-2400-40-2 |

| 3200 | 10'6" | 25 | 7.5 | 5H19-251508-3200-40-2 |

| 4000 | 13'1" | 24 | 9.2 | 5H19-251508-4000-40-2 |

|

|

|

|

|

| 400 | 1'4" | 24 | 1.3 | 5H19-241508-0400-40-2 |

| 800 | 2'7" | 23 | 2.2 | 5H19-231508-0800-40-2 |

|

|

|

|

|

| 600 | 2' | 27 | 1.7 | 5H19-271508-0600-40-2 |

| 1200 | 3'11" | 26 | 3 | 5H19-261508-1200-40-2 |

| 2000 | 6'7" | 24 | 4.8 | 5H19-241508-2000-40-2 |

| 2400 | 7'10" | 24 | 5.7 | 5H19-241508-2400-40-2 |

| 2700 | 8'10" | 24 | 6.3 | 5H19-241508-2700-40-2 |

|

|

|

|

|

| 400 | 1'4" | 35 | 1.3 | 5H19-351810-0400-40-2 |

| 800 | 2'7" | 34 | 2.2 | 5H19-341810-0800-40-2 |

Chisel bit integral

Shank 22mm×108mm

| 400 | 1'4" | 24 | 1.5 | 5H19-241508-0400-40-2 |

| 400 | 1'4" | 29 | 1.5 | 5H19-291508-0400-40-2 |

| 600 | 2' | 27 | 1.7 | 5H19-271508-0600-40-2 |

| 800 | 2'7" | 23 | 2.3 | 5H19-231508-0800-40-2 |

| 800 | 2'7" | 28 | 2.3 | 5H19-281508-0800-40-2 |

| 1200 | 3'11" | 23 | 3.2 | 5H19-231508-1200-40-2 |

| 1600 | 5'3" | 27 | 4.0 | 5H19-271508-1600-40-2 |

| 2000 | 6'7" | 28 | 5.0 | 5H19-281508-2000-40-2 |

| 2400 | 7'10" | 26 | 5.8 | 5H19-261508-2400-40-2 |

| 3200 | 10'6" | 25 | 7.5 | 5H19-251508-3200-40-2 |

Plug hole integral steels

shank 19mm×108mm

| 210 | 17 | 150 | 0.7 | 5H19-171308-0210-40-2 |

| 210 | 20 | 150 | 0.7 |

| 210 | 22 | 150 | 0.7 | 5H19-221308-0210-40-2 |

| 260 | 20 | 200 | 0.8 |

| 260 | 22 | 200 | 0.8 | 5H19-221308-0260-40-2 |

| 310 | 22 | 250 | 0.9 |

| 340 | 20 | 280 | 1.0 | 5H19-201308-0340-40-2 |

| shank 19mm×82mm | 210 | 20 | 150 | 0.7 | 5H19-201308-0210-40-2 |

| 210 | 22 | 150 | 0.7 | 5H19-221308-0210-40-2 |

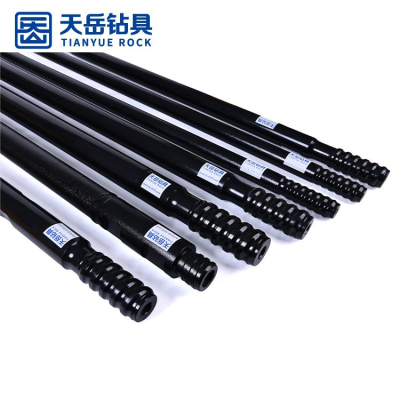

Integral drill steels, commonly used in rock drilling and mining applications, are integral components of drilling systems. The term "integral" indicates that the drill steel and the drill bit are manufactured as a single piece. In the context of your question, you're specifically referring to 19mm integral drill steels.

Diameter:

The "19mm" specification refers to the diameter of the integral drill steel. In this case, it indicates that the diameter of the drill steel is 19 millimeters.

Material:

Integral drill steels are typically made from high-strength steel to withstand the mechanical stresses and abrasion encountered during drilling operations. The choice of material is crucial for the durability and performance of the drill steel.

Integral Design:

Being integral means that the drill steel is manufactured as a single unit with the drill bit. This design offers advantages in terms of rigidity, efficiency, and ease of use, as compared to systems where the bit and steel are separate components.

Applications:

19mm integral drill steels are used in various drilling applications, including in mining, quarrying, and construction. They are integral components of drilling rigs, providing the connection between the rock drill and the drill bit.

Thread Types:

Integral drill steels often have threads at one end for connecting to the rock drill, while the other end is designed to accommodate the drill bit. The specific thread type depends on the manufacturer and the type of drilling equipment used.

Compatibility:

It's crucial to ensure that the 19mm integral drill steels are compatible with the drilling equipment being used. This includes checking the thread type and other specifications to match the components of the drilling rig.

Drilling Efficiency:

The design and quality of the integral drill steel contribute to drilling efficiency. Rigidity, precision, and durability are essential factors for achieving optimal drilling performance.

Maintenance:

Regular inspection and maintenance of integral drill steels are important for ensuring optimal performance. This includes checking for wear, damage, or any signs of fatigue that could affect the integrity of the drill steel.

Integral drill steels are crucial components in the drilling process, and their quality and design significantly impact the efficiency and success of drilling operations. The choice of the appropriate size, compatibility with the drilling rig, and proper maintenance practices are key considerations when using 19mm integral drill steels in various industrial applications.