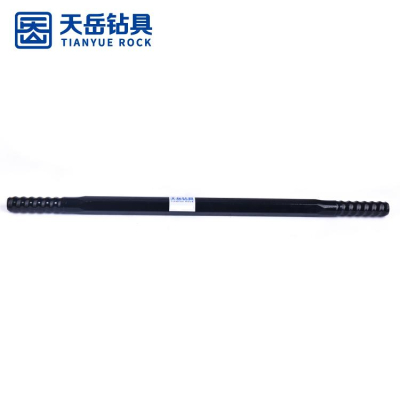

Integral Design:

Integral drill rods are designed as a single piece, meaning the rod and the drill bit form a single integrated unit. This design enhances stability, efficiency, and precision during drilling operations.

Material:

Integral drill rods are typically made from high-quality alloy steel or a similar high-strength material. The choice of material is critical for ensuring the durability and strength required to withstand the forces encountered during drilling in mining applications.

Thread Types:

One end of the integral drill rod is equipped with threads to attach to the rock drill, while the other end is designed to accommodate the drill bit. Common thread types include R-thread (round threads) or T-thread (trapezoidal threads), depending on the drilling equipment specifications.

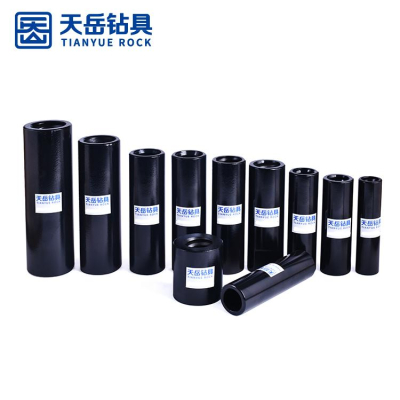

Diameter:

The diameter of integral drill rods varies based on the specific drilling requirements. Common sizes are used in mining operations to achieve the desired hole diameter for various applications.

Length:

Integral drill rods come in different lengths, allowing for customization based on the depth of the drilling required in mining operations. The length of the rod impacts the drilling efficiency and the reach of the drill bit.

Applications:

Integral drill rods are widely used in mining for tasks such as blast hole drilling, exploration drilling, and production drilling. They are essential components for achieving precise and efficient drilling in various rock formations.

Compatibility:

Ensuring compatibility between integral drill rods and the drilling equipment is crucial for safe and efficient drilling operations. Matching the thread type and other specifications is essential for proper assembly.

Drilling Efficiency:

The design of integral drill rods contributes to drilling efficiency by providing stability and transmitting the impact energy from the rock drill to the drill bit. This helps achieve optimal drilling performance in mining applications.

Maintenance:

Regular inspection and maintenance of integral drill rods are important for ensuring optimal performance and safety. Checking for wear, damage, or any signs of fatigue is essential, and replacing worn-out components contributes to the longevity of the drilling equipment.

Integral drill rods are essential tools in the mining industry, contributing to the success of various drilling operations. Proper selection, usage, and maintenance of integral drill rods are crucial for achieving efficient and productive drilling in the challenging conditions of mining environments.