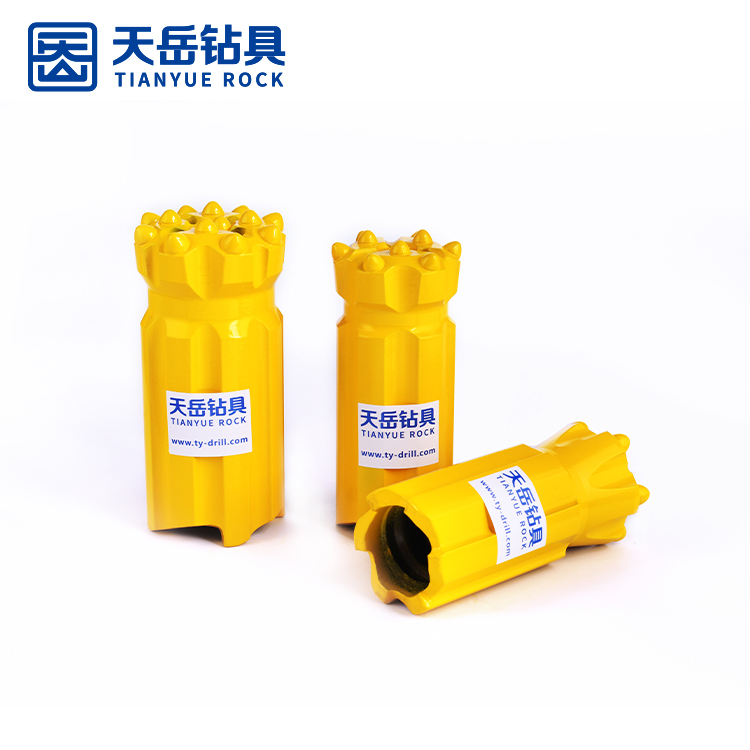

A retrac button bit is a type of drill bit designed for rock drilling applications, especially in challenging and abrasive geological conditions. The term "retrac" refers to a specific design feature where the cutting buttons on the bit are retractable, meaning they can move inward into the bit body. This design is particularly useful in situations where the hardness of the rock formation can vary, allowing the buttons to retract and protect themselves from excessive wear.

| Retrac Button Bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg | TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

| Spherical buttons |

| 64 | 2 1/2 | 3 X 10, 1 X 10 | 6 X 11 | 35° | 3 | - | 2.2 | 1533-64R38-410/611-45-31 |

| 70 | 2 3/4 | 4 X 10, 1 X 10 | 8 X 11 | 35° | 4 | - | 2.4 | 1532-70R38-510/811-45-31 |

| 76 | 3 | 4 X 11, 1 X 11 | 8 X 11 | 40° | 4 | - | 3.3 | 1532-76R38-511/811-45-31 |

| 76 | 3 | 4 X 11, 1 X 11 | 8 X 12 | 35° | 4 | - | 3.3 | 1532-76R38-511/812-45-31 |

| 89 | 3 1/2 | 5 X 12 | 8 X 12 | 35° | 2 | - | 4.8 | 1531-89R38-512/812-45-31 |

| 89 | 3 1/2 | 4 X 13, 1 X 13 | 8 X 13 | 35° | 4 | - | 4.8 | 1532-89R38-513/813-45-31 |

| Parabolic buttons |

| 64 | 2 1/2 | 3 X 10, 1 X 10 | 6 X 11 | 35° | 3 | - | 2.2 | 1533-64R38-410/611-45-51 |

| 70 | 2 3/4 | 4 X 10, 1 X 10 | 8 X 11 | 35° | 4 | - | 2.4 | 1532-70R38-510/811-45-51 |

| 76 | 3 | 4 X 11, 1 X 11 | 8 X 11 | 40° | 4 | - | 3.3 | 1532-76R38-511/811-45-51 |

| 76 | 3 | 4 X 11, 1 X 11 | 8 X 12 | 35° | 4 | - | 3.3 | 1532-76R38-511/812-45-51 |

| 89 | 3 1/2 | 5 X 12 | 8 X 12 | 35° | 2 | - | 4.8 | 1531-89R38-512/812-45-51 |

| 89 | 3 1/2 | 4 X 13, 1 X 13 | 8 X 13 | 35° | 4 | - | 4.8 | 1532-89R38-513/813-45-51 |

Tianyue offers high quality top hammer rock drilling tools,which are widely use in mines, quarries, earthworks and other engineering drilling blasting hole, guardrail hole, mountain reinforcement, anchorage and other engineering holes, geothermal exploration hole, Well bore and other fields.

| Product | Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Face Design | Application |

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt. |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

Button Configuration:

Retrac button bits are equipped with hard, durable buttons (cutting inserts), usually made of tungsten carbide. The buttons are strategically placed on the bit to ensure efficient rock penetration and breaking.

Retrac Design:

The retractable feature allows the cutting buttons to move inward when encountering hard rock, reducing wear and tear. This design enhances the longevity of the bit and contributes to its performance in varying rock conditions.

Tungsten carbide buttons possess unique working properties that make them highly sought-after in various industries. They are extensively utilized in applications such as oil drilling, snow shoveling, snow machines, quarrying, mining, tunnel engineering, and civil building projects.

The numerous advantages of our tungsten carbide buttons are as follows:

1. Our buttons are manufactured using the highest quality carbide, ensuring stable and consistent quality throughout their lifespan.

2. They are processed using the latest manufacturing technology, specifically HIP (Hot Isostatic Pressing) sintering, which guarantees the production of buttons of the utmost quality.

3. We adhere to strict quality checks throughout the entire production process to ensure that every batch of our products meets our customers' standards before being released into the market.

4. Our range of tungsten carbide grades and sizes is extensive, offering customers a wide selection to meet their specific requirements.

5. With our factory-direct shipment system, we are able to ensure short delivery times, allowing our customers to receive their orders promptly.

6. In addition to our high-quality products, we also provide experienced advice to help our customers produce the best possible end products at the lowest possible cost.

7. We understand that customization is often necessary, which is why we offer the option to create custom polished carbide inserts for button bits, allowing our customers to tailor their products to their specific needs.

In conclusion, our tungsten carbide buttons are manufactured using top-quality materials and the latest technology, ensuring consistent quality, short delivery times, and the ability to customize products.

With our expertise and dedication to customer satisfaction, we guarantee the production of high-performing products that meet the needs of various industries.

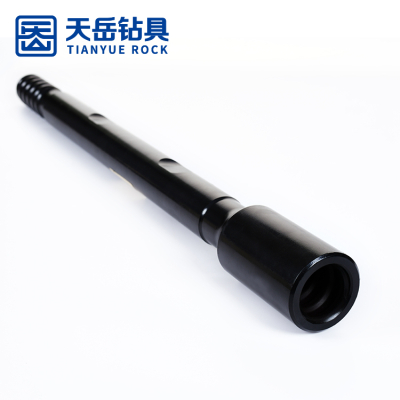

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

At Tianyue, we are proud to offer a wide range of high-quality productive tools and services designed specifically for all top hammer drilling applications. From shank adapters to drill rods, drill bits, accessories, and added value services, you will find everything you need right here.

No matter the application, whether it's underground mining and tunneling, surface mining and quarries, or road and construction projects, we have the top hammer equipment that can meet your needs. We understand the importance of providing efficient and reliable solutions, which is why we continuously develop new and unique products that are not only energy efficient but also cost-effective.

Our commitment to excellence is evident in the quality of our products and services. We strive to provide our customers with the best tools and equipment, ensuring that they can achieve maximum productivity with minimal downtime. We also offer added value services to support our customers throughout the entire drilling process.

With Tianyue, you can trust that you are getting top-of-the-line equipment and services that will help you achieve your drilling goals. Experience the complete solution for your top hammer drilling needs with us.

FAQ

Q1: What quality certificates do you have?

A: ISO9001:2008.

Q2: Where did you export and what was your annual export amount?

A: Over 50 countries,including Europe ,Africa. South America, Mid East and Asia countries etc .Our average annual export amount within recent 3years is 100million USD.

Q3: Do you offer warranty on your products?

A: Yes. For different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The longest period of warranty is 1 years after shipping date.

Q4: How long is your delivery time?

A: 1-2days for the products in stock regular order delivery in 2-3 weeks.