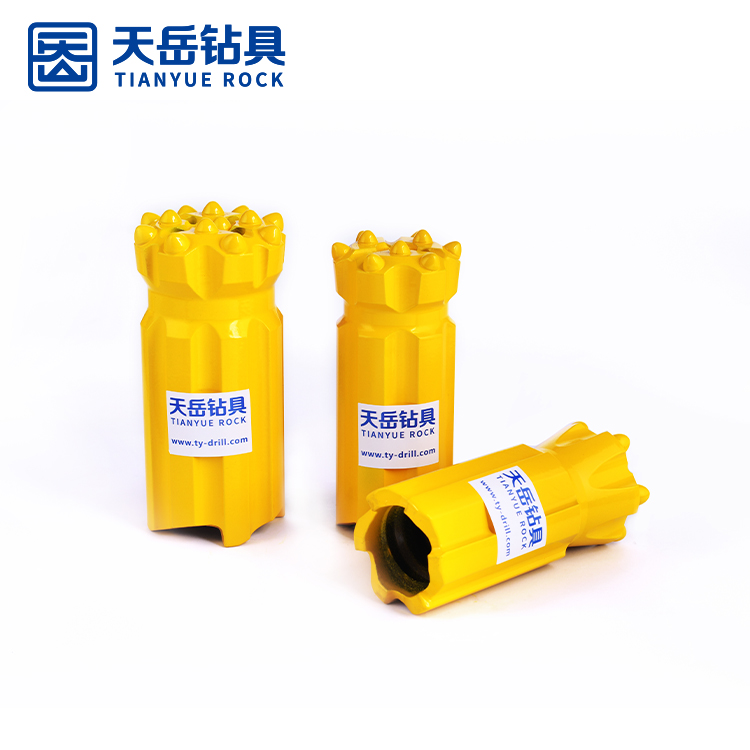

Tianyue retrac button bits are made of high-quality steel and cemented carbide as raw materials, so they have a long service life. And the use of retrac bits minimize the loss of impact energy during transmission. In addition, the advanced button fixing technology makes the fixing force uniform and not easy to loose buttons. Meanwhile, the use of retract drill bits also ensures the perpendicularity of the borehole, so that the impact energy is concentrated on the rock and the drilling efficiency is improved.

As a China retrac button bit supplier, we can provide you with high-quality button bit includes retrac rock drill bits, such as R25 retract button bit, R28 retract button bit, R32 retrac button bit, R35 retrac button bit, R38 retrac button bit, T38 retract drill bit, T45 retract drill bit, T51 retract drill bit, GT60 retract button bit, ST58 retrac button bit, ST68 retrac button bit, SR35 retrac drill bit...

| Retrac Button Bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg | TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

|

|

| Spherical buttons |

| 102 | 4 | 4 X 12, 4 X 12 | 10 X 12 | 35° | 4 | - | 9.3 | 1632-102ST68-812/1012-45-31 |

| 102 | 4 | 4 X 14, 2 X 12 | 8 X 14 | 35° | 4 | - | 9.3 | 1533-102ST68-614/814-45-31 |

| 110 | 4 3/8 | 6 X 14 | 8 X 16 | 35° | 2 | - | 10.0 | 1531-110ST68-614/816-45-31 |

| 115 | 4 1/2 | 6 X 14 | 8 X 16 | 35° | 2 | - | 10.0 | 1531-115ST68-614/816-45-31 |

| 127 | 5 | 8 X 14 | 9 X 16 | 35° | 3 | - | 15.0 | 1531-127ST68-814/916-45-31 |

| 140 | 5 1/2 | 9 X 14 | 9 X 16 | 35° | 3 | - | 17.8 | 1531-140ST68-914/916-45-31 |

| Parabolic buttons |

| 102 | 4 | 4 X 12, 4 X 12 | 10 X 12 | 35° | 4 | - | 9.3 | 1632-102ST68-812/1012-45-51 |

| 102 | 4 | 4 X 14, 2 X 12 | 8 X 14 | 35° | 4 | - | 9.3 | 1533-102ST68-614/814-45-51 |

| 110 | 4 3/8 | 6 X 14 | 8 X 16 | 35° | 2 | - | 10.0 | 1531-110ST68-614/816-45-51 |

| 115 | 4 1/2 | 6 X 14 | 8 X 16 | 35° | 2 | - | 10.0 | 1531-115ST68-614/816-45-51 |

| 127 | 5 | 8 X 14 | 9 X 16 | 35° | 3 | - | 15.0 | 1531-127ST68-814/916-45-51 |

| 140 | 5 1/2 | 9 X 14 | 9 X 16 | 35° | 3 | - | 17.8 | 1531-140ST68-914/916-45-51 |

| Product | Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Face Design | Application |

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

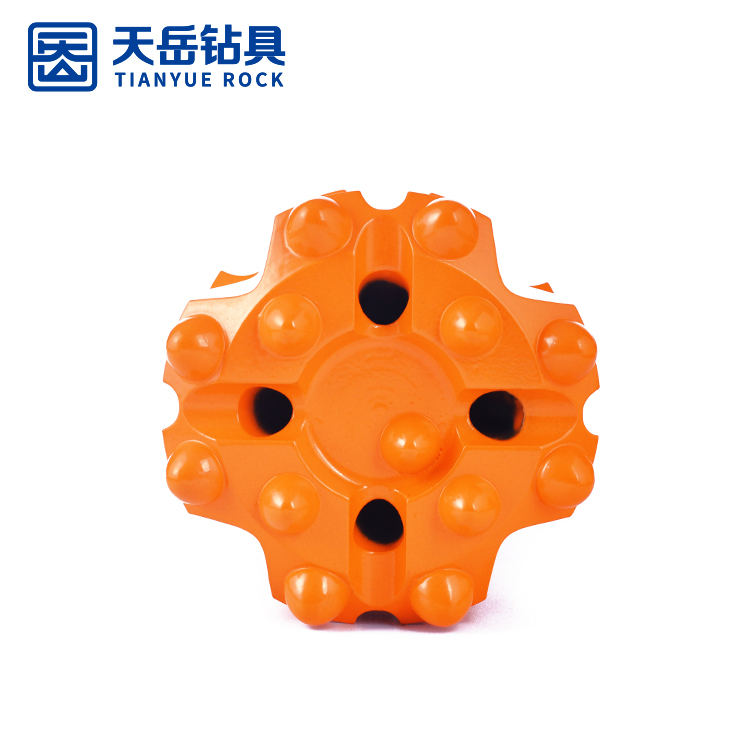

Button Configuration:

Mining retrac button bits are equipped with hard and durable buttons made from materials like tungsten carbide. The button configuration, including the number, size, and arrangement of buttons, is carefully designed for efficient rock penetration and breaking in various mining conditions.

Drilling Application:

These button bits are specifically designed for mining applications, including surface mining and underground mining. They are suitable for drilling blast holes, production drilling, and exploration drilling in a range of rock formations, from medium to hard.

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

FAQ

Q1: I am a small wholesaler, can I place a small order?

A: Yes, of course. If you are a small wholesaler, we are more than happy to accommodate your order. We believe in growing together with our customers. We look forward to establishing new partnerships with friends from all over the world to develop and mutually benefit.

Q2: Can you do OEM for me?

A: Absolutely, we accept all OEM orders. Simply contact us and provide your design. We will offer you a reasonable price and make samples for you as soon as possible.

Q3: How long is your delivery time?

A: Generally, if the goods are in stock, the delivery time is 5-10 days. If the goods are not in stock, it takes 15-20 days, depending on the quantity.

Q4: Do you offer a warranty on your products?

A: Yes, we offer warranties for our products. The duration of the warranty depends on the specific product, but we guarantee coverage for all manufacturing defects in materials and workmanship. The longest warranty period we offer is 12 months from the shipping date.

If you have any other questions, please do not hesitate to send us an inquiry. We will get back to you as soon as possible.