Applications:

T60 Retrac Button Bits are commonly used in percussive drilling methods like top hammer drilling. They are suitable for drilling in hard and abrasive rock formations, making them well-suited for mining, quarrying, and construction applications.

| Retrac Button Bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg | TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

|

|

| Spherical buttons |

| 92 | 3 5/8 | 9 X 12 | 9 X 12 | 40° | 2 | - | 5.4 | 1531-92T60-912/912-45-31 |

| 96 | 3 3/4 | 9 X 12 | 9 X 12 | 40° | 2 | - | 6.3 | 1531-96T60-912/912-45-31 |

| 102 | 4 | 10 X 12 | 9 X 13 | 40° | 2 | - | 7.3 | 1531-102T60-1012/913-45-31 |

| 115 | 4 1/2 | 10 X 12 | 9 X 14 | 35° | 3 | - | 9.8 | 1531-115T60-1012/914-45-31 |

| 118 | 4 5/8 | 6 X 13 | 9 X 16 | 35° | 3 | - | 10.0 | 1531-118T60-613/916-45-31 |

| 127 | 5 | 10 X 13 | 9 X 14 | 35° | 3 | - | 12.0 | 1531-127T60-1013/914-45-31 |

| 140 | 5 1/2 | 10 X 14 | 9 X 16 | 35° | 3 | - | 14.0 | 1531-140T60-1014/916-45-31 |

| 152 | 6 | 12 X 14 | 9 X 16 | 35° | 3 | - | 16.0 | 1531-152T60-1214/916-45-31 |

| Parabolic buttons |

| 92 | 3 5/8 | 9 X 12 | 9 X 12 | 40° | 2 | - | 5.4 | 1531-92T60-912/912-45-51 |

| 96 | 3 3/4 | 9 X 12 | 9 X 12 | 40° | 2 | - | 6.3 | 1531-96T60-912/912-45-51 |

| 102 | 4 | 10 X 12 | 9 X 13 | 40° | 2 | - | 7.3 | 1531-102T60-1012/913-45-51 |

| 115 | 4 1/2 | 10 X 12 | 9 X 14 | 40° | 3 | - | 9.8 | 1531-115T60-1012/914-45-51 |

| 118 | 4 5/8 | 6 X 13 | 9 X 16 | 35° | 3 | - | 10.0 | 1531-118T60-613/916-45-51 |

| 127 | 5 | 10 X 13 | 9 X 14 | 35° | 3 | - | 12.0 | 1531-127T60-1013/914-45-51 |

| 140 | 5 1/2 | 10 X 14 | 9 X 16 | 35° | 3 | - | 14.0 | 1531-140T60-1014/916-45-51 |

| 152 | 6 | 12 X 14 | 9 X 16 | 35° | 3 | - | 16.0 | 1531-152T60-1214/916-45-51 |

| Product | Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Face Design | Application |

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

Material Composition:

These bits are typically made of high-quality steel to withstand the mechanical forces and vibrations associated with drilling.

Carbide buttons are strategically placed on the bit's face to endure the impact and abrasion encountered during drilling.

Drilling Method:

T60 Retrac Button Bits are used with top hammer drills, where the drill string is impacted from above, transferring energy to the bit to break and crush the rock.

Thread Retention Mechanism:

The T60 Retrac Button Bits use a specific thread design for secure connection to the drill string. The thread retention mechanism ensures a reliable and stable connection during drilling operations.

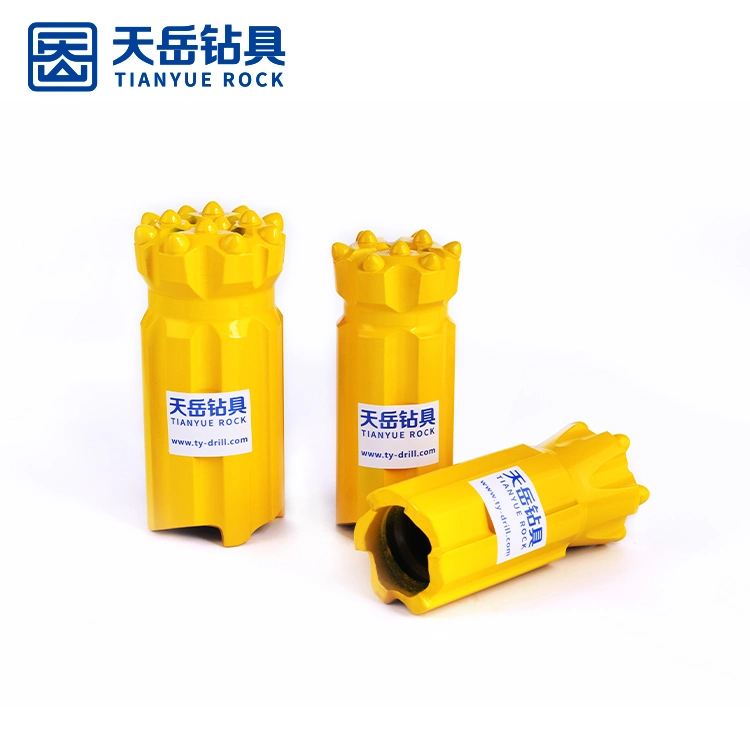

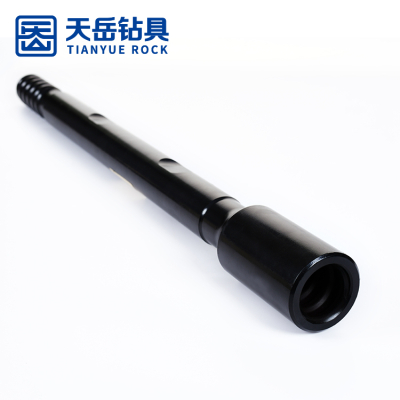

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

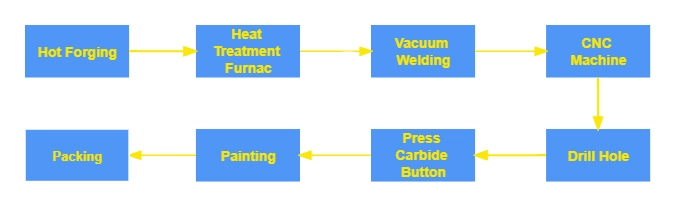

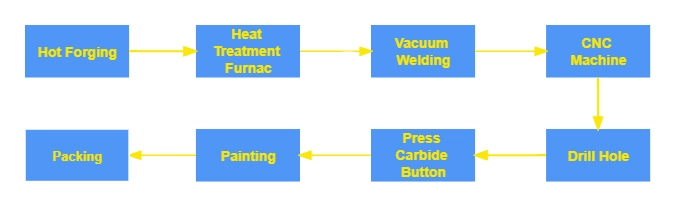

Bit process flow

About US

Packing

Variations:

T60 Retrac Button Bits may come in various sizes and designs to suit different drilling requirements and rock types.

When using T60 Retrac Button Bits, it's essential to follow the manufacturer's recommendations for proper use, maintenance, and replacement intervals. These bits play a crucial role in the efficiency and success of drilling operations in challenging geological conditions.