Road milling tools, also known as road milling bits or asphalt milling cutters, are cutting tools used in road milling machines or cold planers. These tools are essential in the process of removing and reclaiming the existing pavement surface on roads and highways. Road milling is a common method for resurfacing, rehabilitation, or upgrading road surfaces. Here are key features and information about road milling tools:

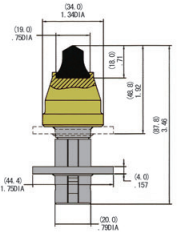

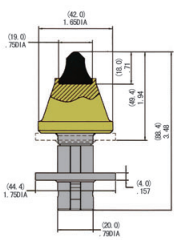

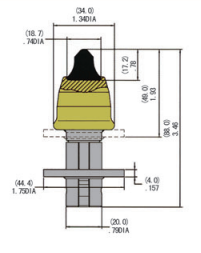

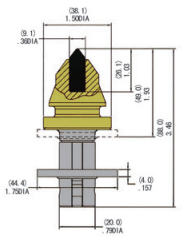

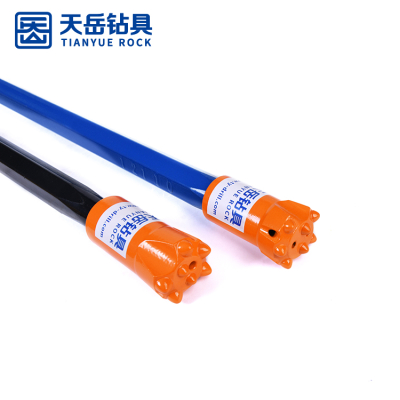

Design:

Road milling tools are designed to break and remove the asphalt or concrete surface of roads. They are part of the cutting drum assembly of road milling machines.

Material:

The cutting tools are typically made from hard and wear-resistant materials, such as tungsten carbide or high-speed steel. Tungsten carbide is commonly used for its hardness, durability, and resistance to abrasion.

Types of Milling Tools:

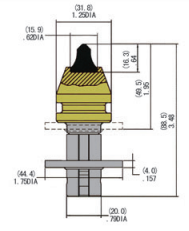

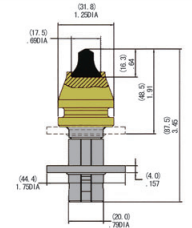

Standard Bits: Used for general-purpose milling in relatively soft materials.

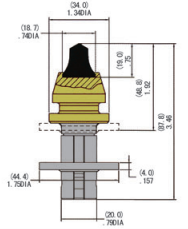

Step Bits: Feature a stepped profile for enhanced cutting efficiency.

Double-Reduction Bits: Designed for tougher materials and heavy-duty milling.

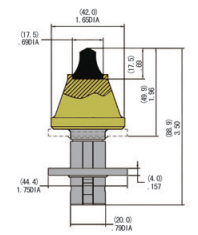

Road Razor Bits: Known for their aggressive cutting performance in asphalt.

Various types of milling tools are available to suit different milling applications:

Arrangement on the Cutting Drum:

The milling tools are strategically arranged on the milling drum to ensure effective and uniform material removal.

Rotation Speed:

The rotation speed of the milling drum, as well as the arrangement and shape of the cutting tools, are factors that impact the efficiency and quality of the milling process.

Milling Depth:

The milling depth is adjustable, allowing operators to control how much material is removed from the road surface in a single pass.

Durability:

Durability is a critical factor for road milling tools, as they are subjected to significant wear and impact during the milling process. Tungsten carbide tips contribute to their long lifespan.

Versatility:

Road milling machines equipped with various types of cutting tools can be used for different applications, including milling asphalt, concrete, or removing road markings.

Maintenance:

Regular inspection and maintenance of the cutting tools are essential for optimal performance. Worn or damaged tools should be replaced promptly to maintain milling efficiency.

Safety Considerations:

Safety is a priority in road milling operations. Proper training, adherence to safety protocols, and the use of personal protective equipment (PPE) contribute to the well-being of operators.

Road milling tools play a crucial role in the rehabilitation and maintenance of road surfaces. The efficiency and effectiveness of this process depend significantly on the quality and condition of the cutting tools used in the road milling machines.