Coupling sleeves are essential components in rock drilling, serving to connect various segments of the drill string, such as shank adapters, drill rods, and drill bits. They ensure continuity in the drill string and facilitate the efficient transfer of rotational and percussive forces. Here's a detailed overview of coupling sleeves and the types available:

Coupling Sleeves Overview

1. Definition

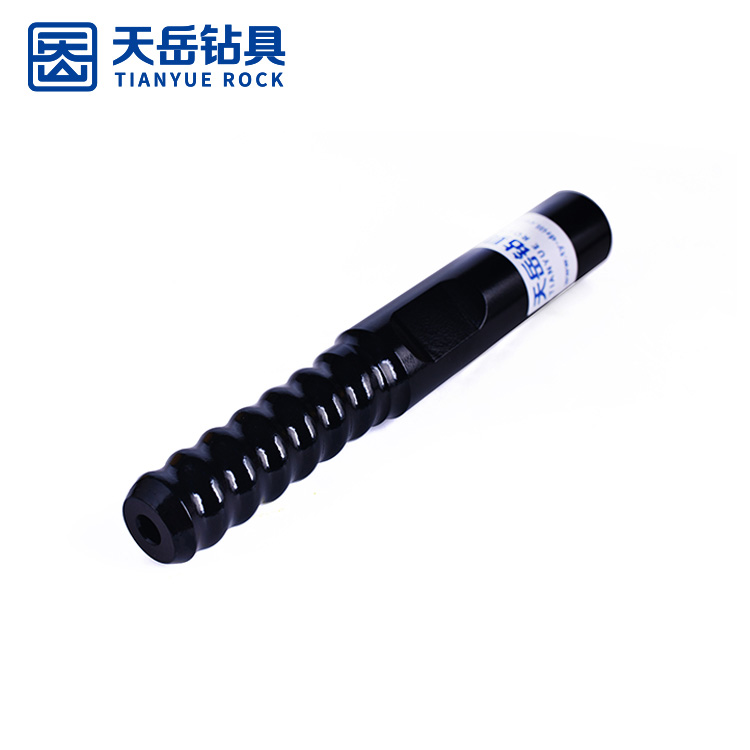

Coupling sleeves are cylindrical components with internal threads used to join two sections of a drill string, such as a shank adapter to a drill rod or two drill rods. These sleeves ensure the stability and integrity of the drill string during drilling operations.

2. Function

The primary function of coupling sleeves is to securely connect different components of the drill string, ensuring efficient transmission of drilling forces and maintaining alignment. They play a crucial role in:

Force Transmission: Facilitating the transfer of rotational and impact energy from the drill machine to the drill bit.

Stability: Providing structural integrity and stability to the drill string.

Flexibility: Allowing for the extension of the drill string to achieve greater drilling depths.

3. Types of Coupling Sleeves

Semi-Bridge Couplings

Design: These couplings have a bridge in the middle, which prevents the ends of the drill rods from coming into contact, reducing wear and prolonging the life of the rods.

Application: Used where moderate stress and torque are encountered. They provide a balance between flexibility and durability.

Full-Bridge Couplings

Design: These couplings have a complete internal bridge, which centers the drill rods and prevents direct contact between the ends.

Application: Ideal for high-stress applications where the highest degree of rod protection is needed. They ensure precise alignment and reduce rod wear.

Crossover Couplings

Design: These couplings are used to connect drill rods with different thread types or sizes. They have different thread patterns on each end.

Application: Useful in operations requiring the transition from one type of drill rod to another, offering versatility in the drill string setup.

4. Applications

Coupling sleeves are used in various drilling applications, including:

Mining: For connecting components in blast hole drilling and exploration drilling.

Construction: In foundation drilling, tunnel boring, and other heavy construction tasks.

Quarrying: Used in the extraction of stone and minerals.

Geotechnical Drilling: For soil sampling and geological surveys.

5. Key Features

Material: Typically made from high-grade alloy steel to ensure strength and durability under high-stress conditions.

Thread Compatibility: Internal threads designed to match the threads of shank adapters and drill rods, ensuring a secure and tight connection.

Heat Treatment: Often heat-treated to enhance wear resistance and extend the service life of the coupling.

Precision Engineering: Manufactured with tight tolerances to ensure proper alignment and effective force transmission.