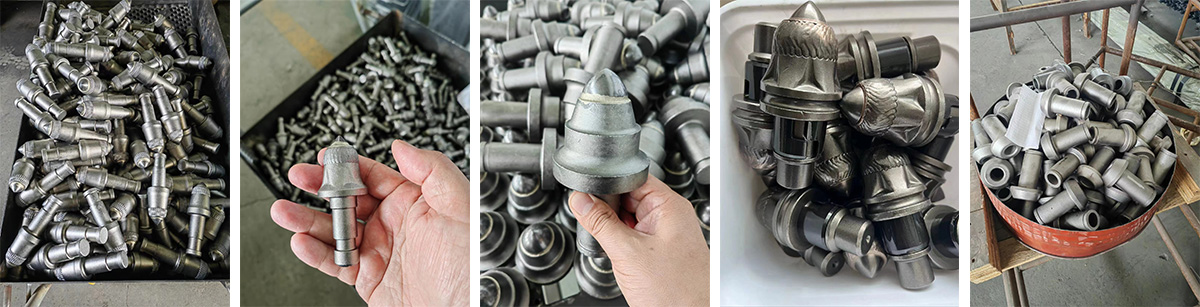

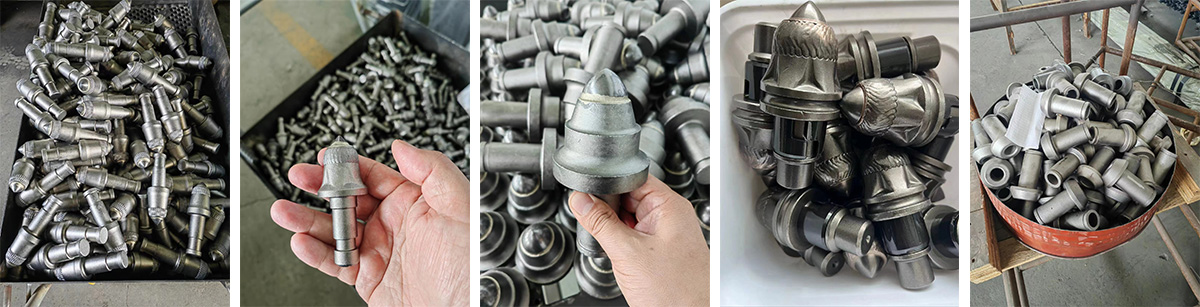

Engineering rotary digging teeth are composed of three parts: main alloy (tungsten carbide alloy), matrix (high-quality alloy structural steel), and circlip (spring steel). The main alloy is effectively welded with the parent body through advanced brazing technology, and the shear strength of the brazed seam is ≥180MPa. The mother body rod is equipped with a special groove structure for placing the circlip. The circlip is mechanically assembled and connected to the mother body. Through the tensioning force of the circlip, the mounting gear seat can effectively grasp the rotary digging teeth.

Wear-resistant layer:

We use imported wear-resistant welding wire, which has good bonding performance with the tooth body, strong wear resistance, and good surfacing performance. The surfacing thickness can be thickened as needed.

Alloy aspects:

The alloy material is cold isostatically pressed ultra-coarse grained KE13 grade with strong collapse resistance. The alloy form is a rock tooth alloy specially designed for rock passing. This form of alloy is suitable for working in hard rock and ultra-hard rock conditions.

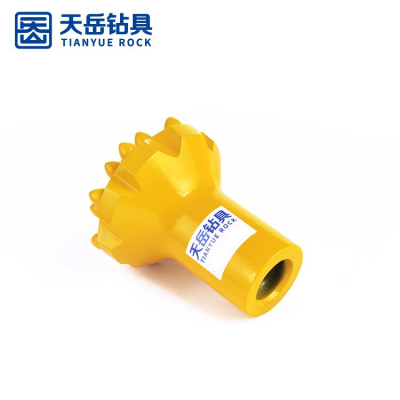

Product number | Pick length (mm) | Length of head (mm) | Pick hanldle diameter (mm) | PDC insert diameter (mm) | Pick head diameter (mm) |

U82 | 152 | 80 | 30 | 14 | 50 |

U84 | 142 | 70 | 30 | 16 | 50 |

U85 | 161 | 85 | 30 | 14 | 50 |

U92 | 195 | 101 | 35 | 16 | 55 |

U94 | 183 | 90 | 35 | 19 | 55 |

U95 | 182 | 88 | 35 | 24 | 55 |

U170 | 215 | 89 | 43 | 22 | 64 |

D47 | 140 | 65 | 30 | 23 | 50 |

D120 | 143 | 68 | 30 | 16 | 55 |

D135 | 155 | 80 | 38 | 19 | 63 |