About us

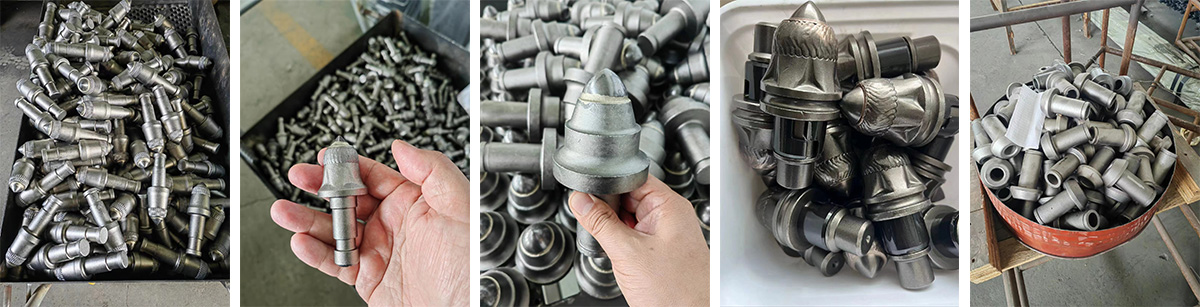

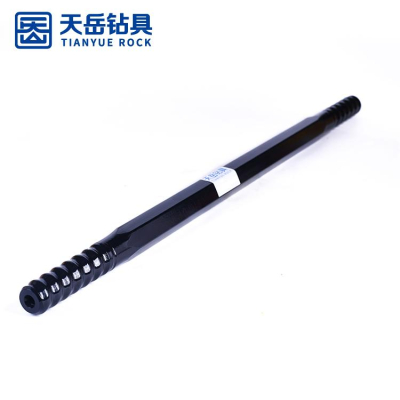

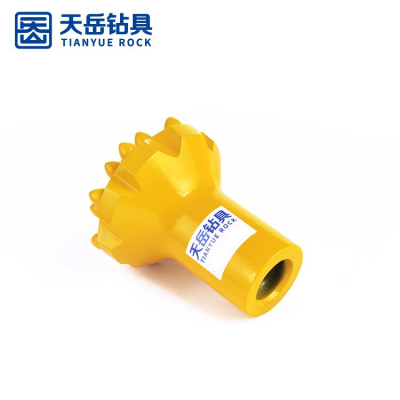

Shandong Yanggu Tianyue Drilling Tools Co, Ltd.

News

Shandong Yanggu Tianyue Drilling Tools Co, Ltd.