Material:

T51 Mining Speed Rods are typically made from high-strength steel to withstand the stresses and forces encountered during mining drilling operations.

Product | Drill Rod |

Other Names | Drill rod,Drill pipe,Extension drill rod,Hollow bar,Top hammer drill rod,Excavation drill rod,Rock drill rod,Round drilling rod,Hex drill rod,Tomroc dill pipe,Rock drilling tools,Rock drill tools,Rock drilling tools,Threaded drill rod,Mining drill rod,Thread rock drill rod |

Material | 23CrNi3Mo |

Application | Bench Drilling, Production drilling, Long hole drilling, Drifting,Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting |

Thread | R22, R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35... |

Rod Type | Extension Rod,MF Rod,Speedrod,Drifter Rod,Guide Tube,Drill tube |

Boby Type | Round drill rod,Hexagonal drill rod |

Length | 260mm~6400mm |

Diameter | 20mm~87mm |

Custom Design | Size,Color |

Application:

T51 Mining Speed Rods are specifically designed for use in mining applications, including exploration drilling, blast hole drilling, and other tasks associated with extracting minerals and resources.

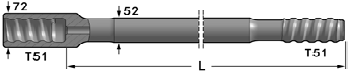

| MF Rod | Length | Diameter | Weight

approx

kg | TIANYUE P/N |

| mm | Foot | mm | inch |

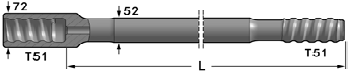

MF-rod T51-Round52-T51 MF-rod T51-Round52-T51

Flushing hole 21.5mm.

| 1525 | 5' | 52 | 2 | 26.2 | 24R52-T51/72-1525-23 |

| 1830 | 6' | 52 | 2 | 30.6 | 24R52-T51/72-1830-23 |

| 3050 | 10' | 52 | 2 | 48.3 | 24R52-T51/72-3050-23 |

| 3660 | 12' | 52 | 2 | 57.1 | 24R52-T51/72-3660-23 |

| 4270 | 14' | 52 | 2 | 66.0 | 24R52-T51/72-4270-23 |

| 4880 | 16' | 52 | 2 | 74.8 | 24R52-T51/72-4880-23 |

| 5530 | 18' | 52 | 2 | 84.2 | 24R52-T51/72-5530-23 |

| 6095 | 20' | 52 | 2 | 92.4 | 24R52-T51/72-6095-23 |

Compatibility:

T51 Mining Speed Rods are designed to be compatible with drilling equipment commonly used in the mining industry. This includes various drilling rigs, jumbos, and bolting machines.

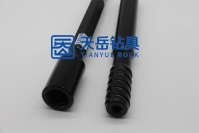

Rod Shape |

| R:Round

MF rod,Guide Tube,Extension Rod |

| H: Hex

Drifter Rod |

Length Options:

Rods are available in different lengths to accommodate specific mining drilling requirements. The choice of length depends on factors such as drilling depth and equipment specifications.

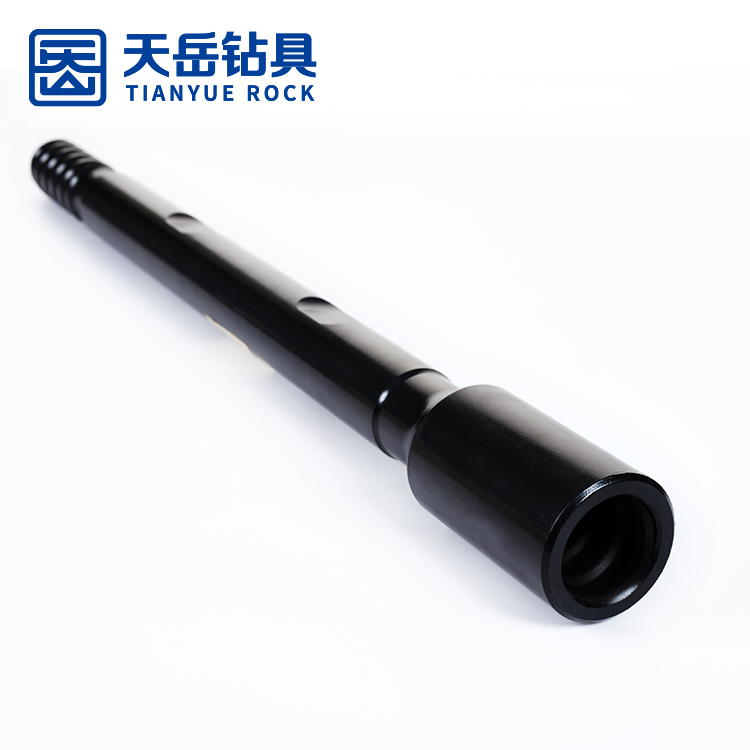

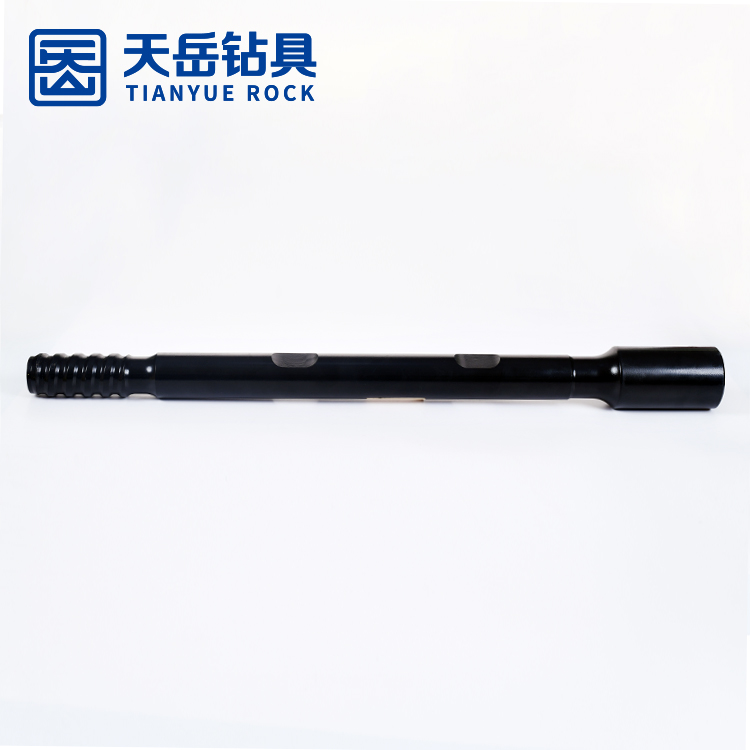

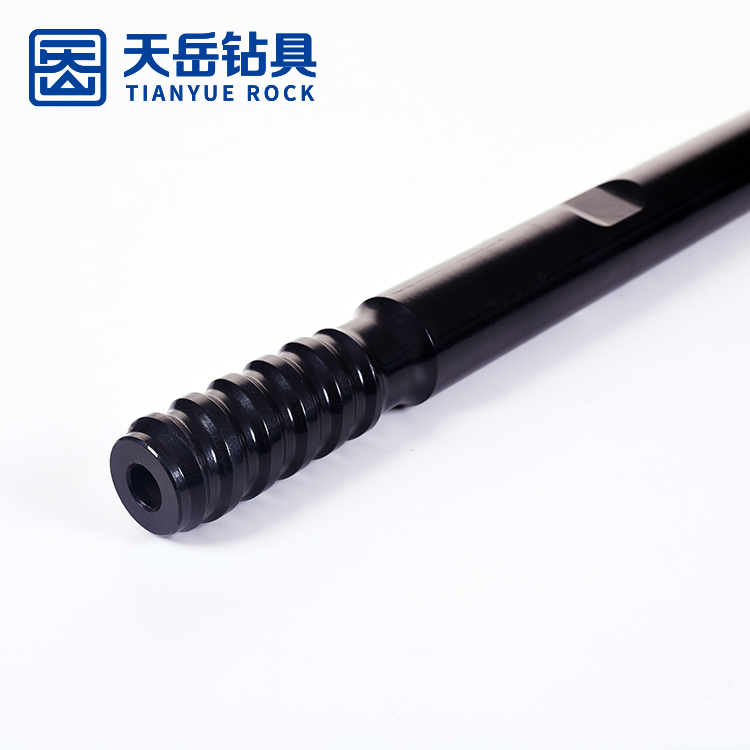

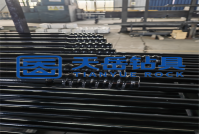

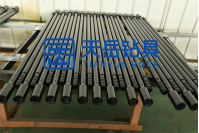

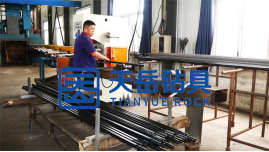

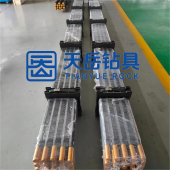

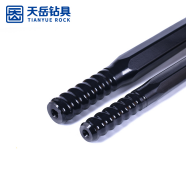

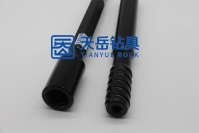

Actual pictures of drill rods |

| Extension Rod |

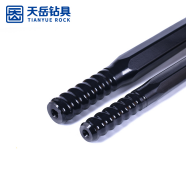

| Speed Rod |

|

Drifter Rod |

| Guide Tube |

Thread Design:

The thread design of T51 Mining Speed Rods is typically a standard type that facilitates efficient and secure connections with other threaded components.

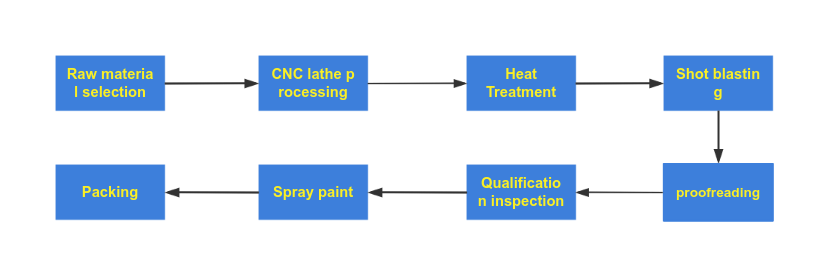

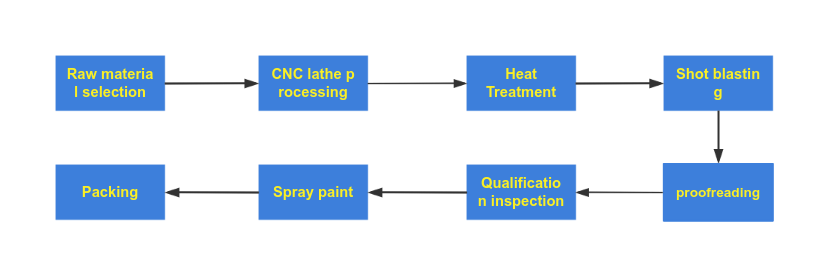

Rod process flow

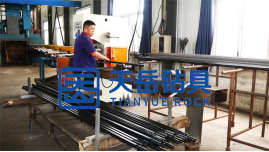

About US

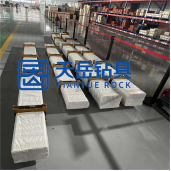

Packing

Speed Handling:

The term "Speed Rods" implies that these rods are designed for quick and efficient rod handling during mining drilling operations, contributing to faster and more productive drilling.

Durability:

Given the challenging and abrasive conditions in mining environments, T51 Mining Speed Rods are designed for durability. Wear-resistant materials, such as tungsten carbide inserts, may be incorporated to extend the lifespan of the rods.

As specific product details, features, and applications can vary between manufacturers, it is recommended to consult with suppliers, manufacturers, or distributors specializing in mining drilling equipment and accessories for the most accurate and up-to-date information. They can provide detailed specifications and guidance on the selection and use of T51 Mining Speed Rods in mining applications.