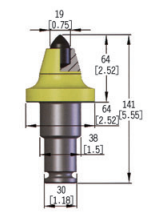

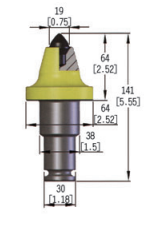

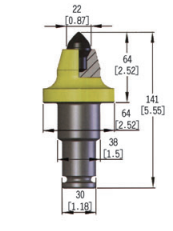

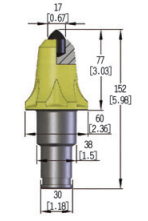

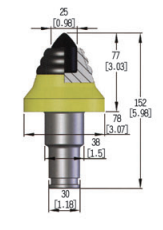

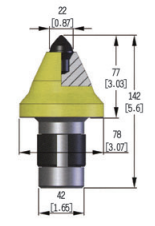

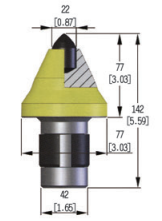

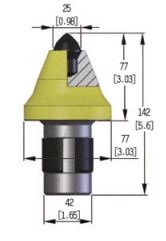

Design:

Surface mining bits are designed to efficiently break and cut through various types of geological materials found on the earth's surface. The design often includes a carbide tip or insert for enhanced hardness and wear resistance.

Material:

The cutting tips or inserts of surface mining bits are typically made from hard materials like tungsten carbide. Tungsten carbide provides excellent wear resistance, making it suitable for the abrasive conditions encountered in surface mining.

Bit Types:

Conical Bits: Featuring a conical shape, these bits are effective for cutting in softer formations.

Chisel Bits: With a straight and flat cutting edge, chisel bits are suitable for harder formations.

Step Bits: These bits have a stepped profile, providing multiple cutting edges for improved efficiency.

Surface mining bits come in various types to suit different geological conditions and mining methods:

Applications:

Open-Pit Mining: In large-scale mining operations where minerals are extracted from open pits or quarries.

Quarrying: For the extraction of stone, sand, and other materials from quarries.

Construction: In construction projects that involve excavation and earthmoving.

Surface mining bits are used in various applications, including:

Compatibility:

Surface mining bits are designed to be compatible with specific types of mining equipment, such as drilling rigs, excavators, or continuous miners. Compatibility ensures proper fitment and functionality.

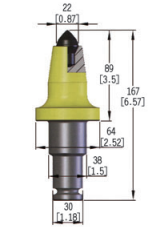

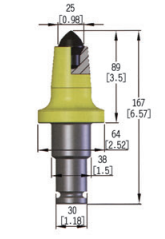

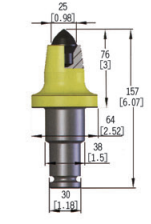

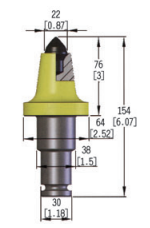

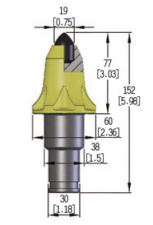

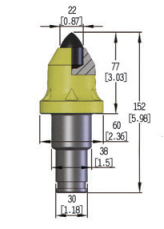

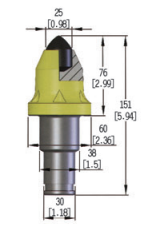

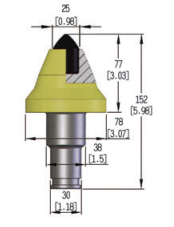

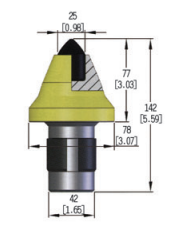

Sizes and Configurations:

Surface mining bits come in different sizes and configurations to accommodate various geological conditions and mining requirements. The selection of the appropriate size depends on factors such as material hardness and desired drilling depth.

Durability:

Durability is a crucial factor for surface mining bits, considering the demanding conditions in surface mining operations. Tungsten carbide tips contribute to the longevity and wear resistance of the bits.

Maintenance:

Regular inspection and maintenance of surface mining bits are essential for optimal performance. Checking for wear and replacing worn tips or bits contribute to the efficiency and longevity of the cutting tools.

Safety Considerations:

Safety is a paramount concern in surface mining. Proper training, adherence to safety protocols, and the use of appropriate personal protective equipment (PPE) are essential for the well-being of operators.

Surface mining bits are critical components in the extraction of minerals and materials from the earth's surface. The proper selection, use, and maintenance of these bits contribute to the efficiency and success of surface mining operations.