Features:

Threaded Drill Bits are essential tools used in various construction projects such as tunneling, underground mining, open pit mining, anchoring, and other large-scale construction projects. These bits come in different types including regular, retract, and reaming, each serving specific purposes.

One of the key advantages of Threaded Drill Bits is their strong button-fixing ability. This feature ensures that the buttons or cutting elements of the drill bits remain securely in place, even under heavy use. As a result, these bits can withstand the rigors of demanding drilling applications, offering a longer service life compared to other types of drill bits.

Additionally, Threaded Drill Bits are known for their excellent wear-resistance and impact-resistance performance. This means that these bits can withstand the abrasiveness of the materials being drilled and the high levels of impact and vibration associated with drilling operations. This durability allows for efficient and effective drilling, reducing downtime and increasing productivity on construction sites.

Due to their superior performance, Threaded Drill Bits have gained popularity in the construction industry. These bits are widely used in various applications such as creating tunnels, extracting minerals in underground or open pit mining operations, and anchoring structures in construction projects. The versatility and reliability of Threaded Drill Bits make them a go-to choice for contractors and construction professionals.

In conclusion, Threaded Drill Bits offer numerous advantages including stronger button-fixing ability, longer service life, better wear-resistance, and impact-resistance performance. Their wide range of applications and reliability make them essential tools in large-scale construction projects. Whether it is tunneling, mining, or anchoring, these drill bits provide the durability and efficiency required to successfully complete the task at hand.

Product |

Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

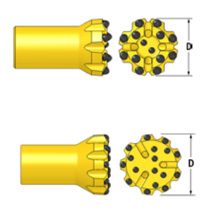

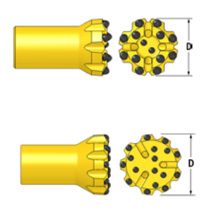

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Button bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg | TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

| Spherical Buttons |

| 92 | 3 5/8 | 4×13,1×13 | 8×13 | 35° | 4 | 一 | 5.3 | 1432-92T60-513/813-45-31 |

| 96 | 3 3/4 | 4×13,1×13 | 8×14 | 35° | 4 | 一 | 5.6 | 1432-96T60-513/814-45-31 |

| 102 | 4 | 9×11 | 9×13 | 35° | 3 | 一 | 6 | 1431-102T60-911/913-45-31 |

| 115 | 4 1/2 | 10×12 | 9×14 | 35° | 3 | 一 | 6.8 | 1431-115T60-1012/914-45-31 |

| 127 | 5 | 10×13 | 9×14 | 35° | 3 | 一 | 7.5 | 1431-127T60-1013/914-45-31 |

| 140 | 5 1/2 | 10×14 | 9×16 | 35° | 3 | 一 | 9 | 1431-140T60-1014/916-45-31 |

| 152 | 6 | 12×14 | 9×16 | 35° | 3 | 一 | 10.6 | 1431-152T60-1214/916-45-31 |

| Parabolic Buttons |

| 92 | 3 5/8 | 4×13.1×13 | 8×13 | 35° | 4 | 一 | 5.3 | 1432-92T60-513/813-45-51 |

| 96 | 3 3/4 | 4×13,1×13 | 8×14 | 35° | 4 | 一 | 5.6 | 1432-96T60-513/814-45-51 |

| 102 | 4 | 9×11 | 9×13 | 35° | 3 | 一 | 6 | 1431-102T60-911/913-45-51 |

| 115 | 4 1/2 | 10×12 | 9×14 | 35° | 3 | 一 | 6.8 | 1431-115T60-1012/914-45-51 |

| 127 | 5 | 10×13 | 9×14 | 35° | 3 | 一 | 7.5 | 1431-127T60-1013/914-45-51 |

| 140 | 5 1/2 | 10×14 | 9×16 | 35° | 3 | 一 | 9 | 1431-140T60-1014/916-45-51 |

| 152 | 6 | 12×14 | 9×16 | 35° | 3 | 一 | 10.6 | 1431-152T60-1214/916-45-51 |

| Face Design | Application |

|

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

|

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

|

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

|

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

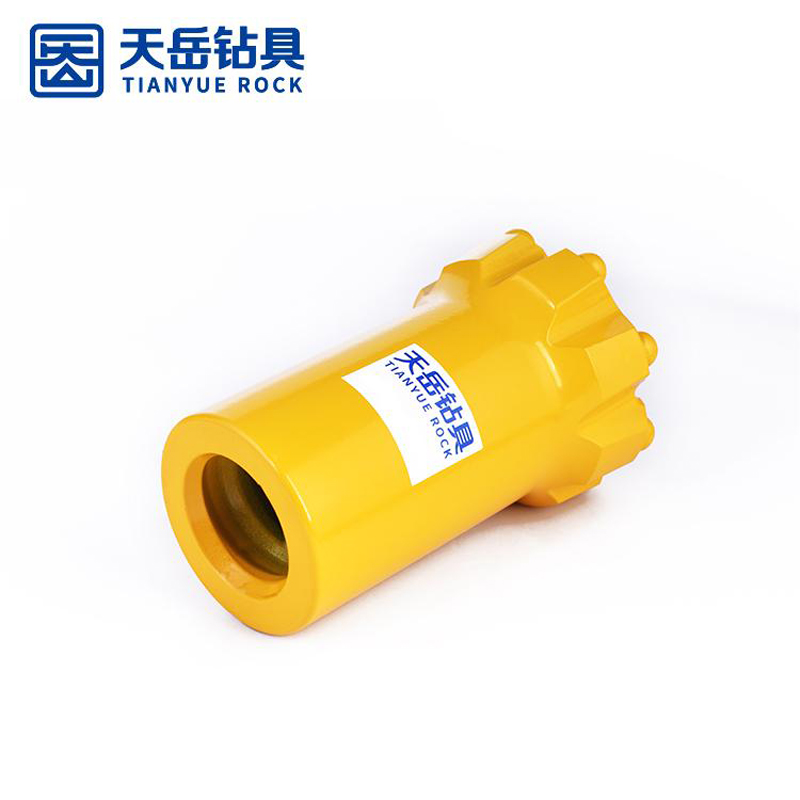

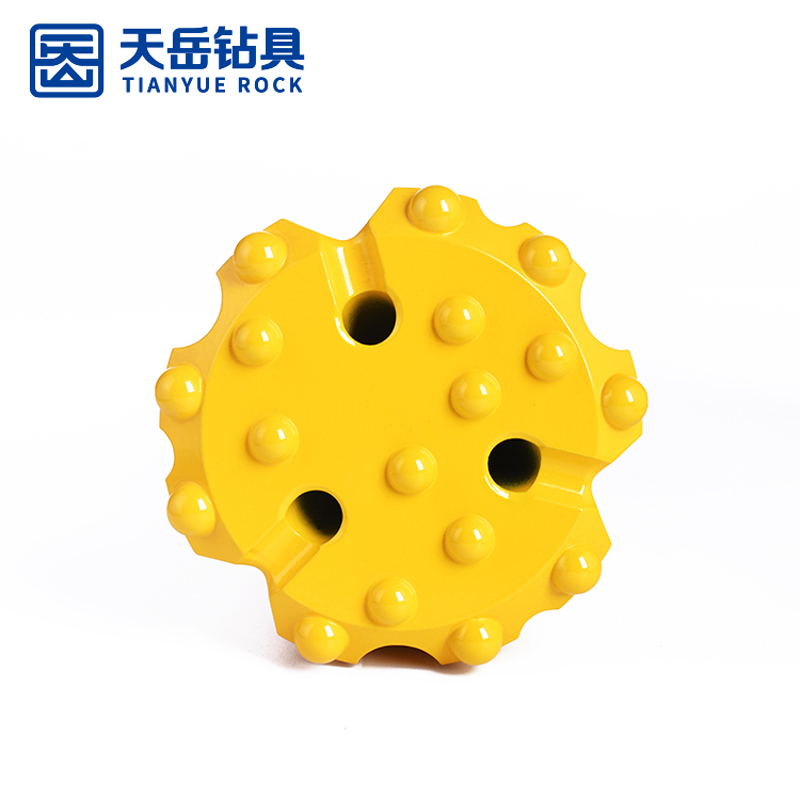

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

FAQ

Q1.How can lget abooklet and buy a product from you?

Very easy! Just leave me a message and tell me your requirements, let me konw you are interesting in our products.

will talk with you for the detail soon.

Q2.Can you tell me your size and specification.

1. Give me your drawing with detail requirements.

2. Give me the product no. after you checked our booklet.

3. Don’t forget to tell me the quantities, this is very important.

4. Give me your size and specirication.

5. Your destination port.

Q3.what can you buy from us?

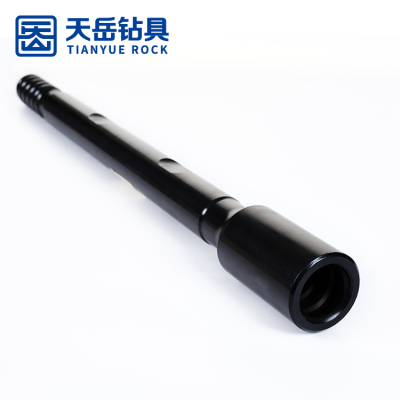

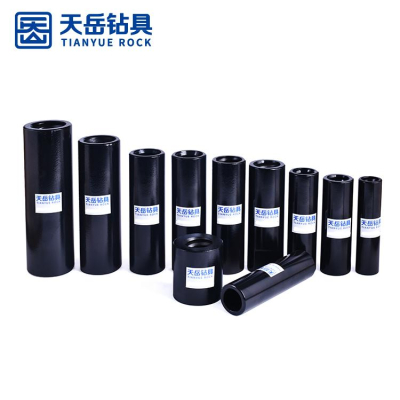

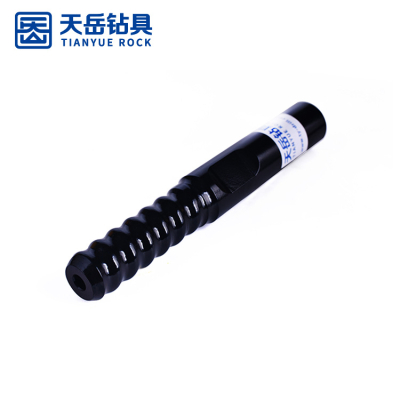

Drill Bit,Drill Rod,Coupling sleeve,Shank Adapter,Coal Mining Picks,Drill small hole,Taper Bit,Taper Rod,Integral steels,MF rod...

If any other query, please do not hesitate to send me an inquiry. I will feedback asap.