Features:

The "Tianyue" brand rock drilling bits produced by our company have the following properties:

1.High enough surface hardness. It can improve the wear resistance of rock drilling bits, the ability of rock drilling bits to resist contact fatigue and bending fatigue, and the surface has a certain plasticity, which can reduce stress concentration and improve the service life of rock drilling tools.

2.Good strength and toughness matching. While the surface has high hardness, high strength and a certain degree of plasticity, the core of the rock drilling tool has high yield strength and toughness, so that the surface of the rock drilling tool can be carburized when it bears a large contact stress or bending load. The layer transition area will not cause early damage to the seepage layer due to plastic deformation.

3.Good processing performance. It is required that the steel has good plasticity at high temperature, and the forgings are easy to form during the forging process; at the same time, it should have good cutting performance, the hardness after annealing is less than HB260, but it is not easy to be too soft, so as not to stick to the knife and affect its processing quality; hardenability Well, the air-cooled hardness should reach HRC35-50; the drilling tool steel for hot cogs should have a high coefficient of linear expansion in the temperature range of the hot cogs, and maintain high hardness, strength and toughness in a reasonable match.

4.Certain corrosion resistance.

Button bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg |

TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

| Spherical Buttons |

37

| 1 29/64 | 2×7 | 5×9 | 30° | 1 | 1 | 0.5 | 1431-37R28-27/59-45-41 |

| 38 | 1 1/2 | 2×8 | 4×9 | 30° | 1 | 2 | 0.6 | 1431-38R28-28/49-45-41 |

| 38 | 1 1/2 | 2×7 | 5×9 | 30° | 1 | 1 | 0.6 | 1431-38R28-27/59-45-41 |

| 41 | 1 5/8 | 2×8 | 5×9 | 35° | 1 | 1 | 0.7 | 1431-41R28-28/59-45-41 |

| 43 | 1 11/16 | 2×9 | 5×9 | 35° | 1 | 2 | 0.8 | 1431-43R28-29/59-45-41 |

| 45 | 1 3/4 | 2×9 | 5×10 | 30° | 1 | 2 | 0.9 | 1431-45R28-29/510-45-41 |

| 45 | 1 3/4 | 3×8 | 6×9 | 35° | 1 | 3 | 0.9 | 1431-45R28-38/69-45-41 |

| Parabolic Buttons |

| 37 | 1 29/64 | 2×7 | 5×9 | 30° | 1 | 1 | 0.5 | 1431-37R28-27/59-45-51 |

| 38 | 1 1/2 | 2×8 | 4×9 | 30° | 1 | 2 | 0.6 | 1431-38R28-28/49-45-51 |

| 38 | 1 1/2 | 2×7 | 5×9 | 30° | 1 | 1 | 0.6 | 1431-38R28-27/59-45-51 |

| 41 | 1 5/8 | 2×8 | 5×9 | 35° | 1 | 1 | 0.7 | 1431-41R28-28/59-45-51 |

| 43 | 1 11/16 | 2×9 | 5×9 | 35° | 1 | 2 | 0.8 | 1431-43R28-29/59-45-51 |

| 45 | 1 3/4 | 2×9 | 5×10 | 30° | 1 | 2 | 0.9 | 1431-45R28-29/510-45-51 |

| 45 | 1 3/4 | 3×8 | 6×9 | 35° | 1 | 3 | 0.9 | 1431-45R28-38/69-45-51 |

| 48 | 1 7/8 | 2×9 | 5×11 | 30° | 1 | 2 | 1 | 1431-48R28-29/511-45-51 |

| 48 | 1 7/8 | 3×8 | 6×9 | 35° | 1 | 3 | 1 | 1431-48R28-38/69-45-51 |

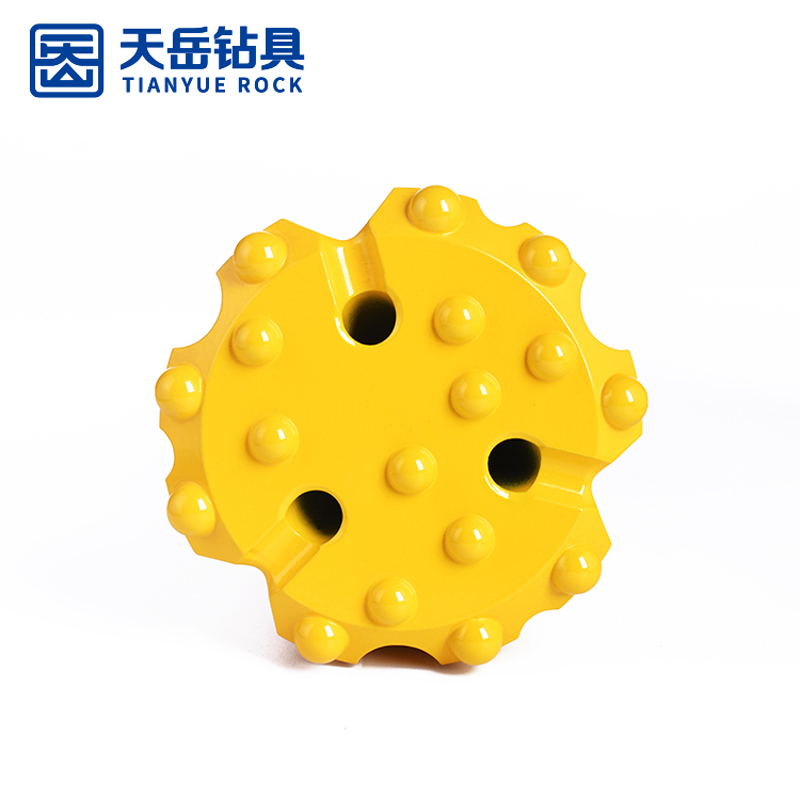

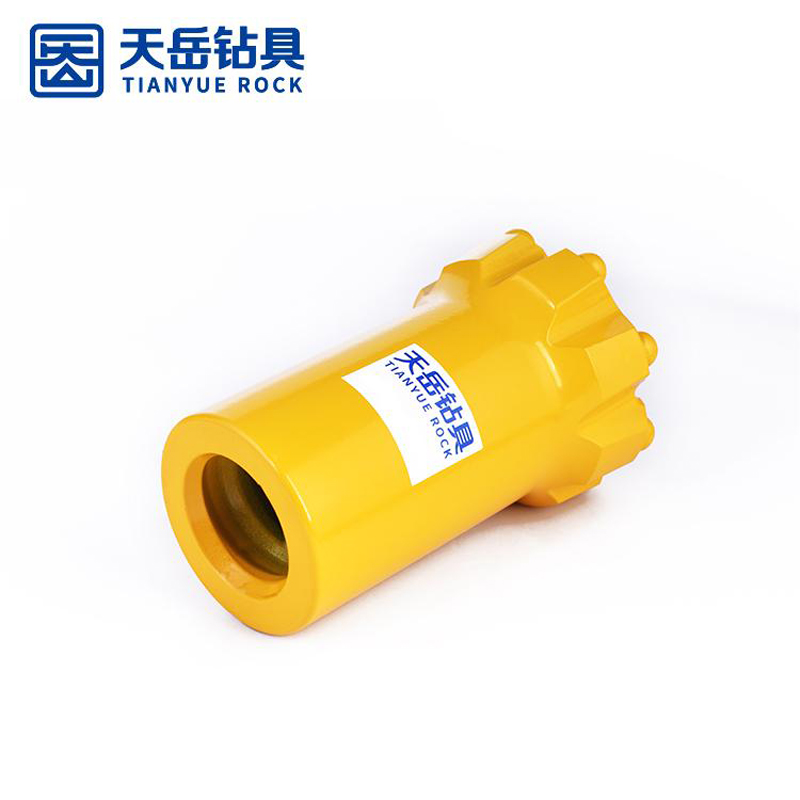

Product |

Button Bit |

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

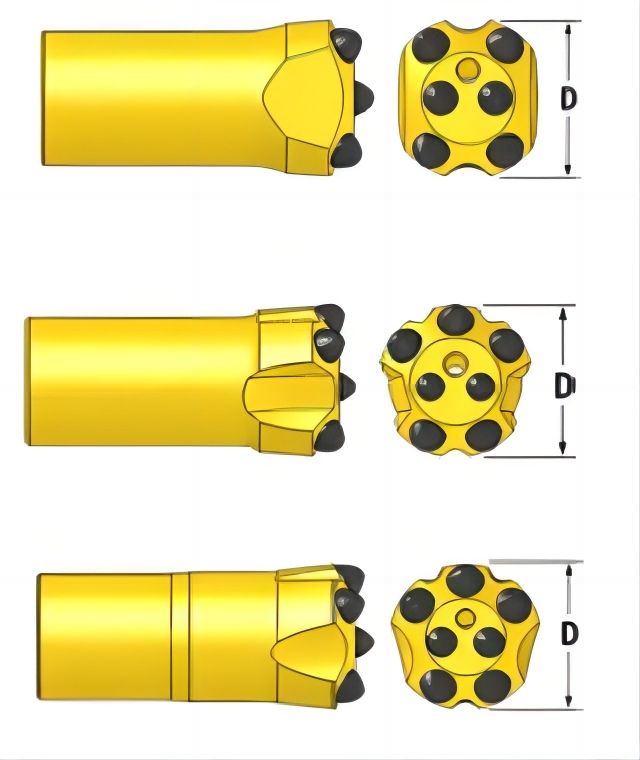

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

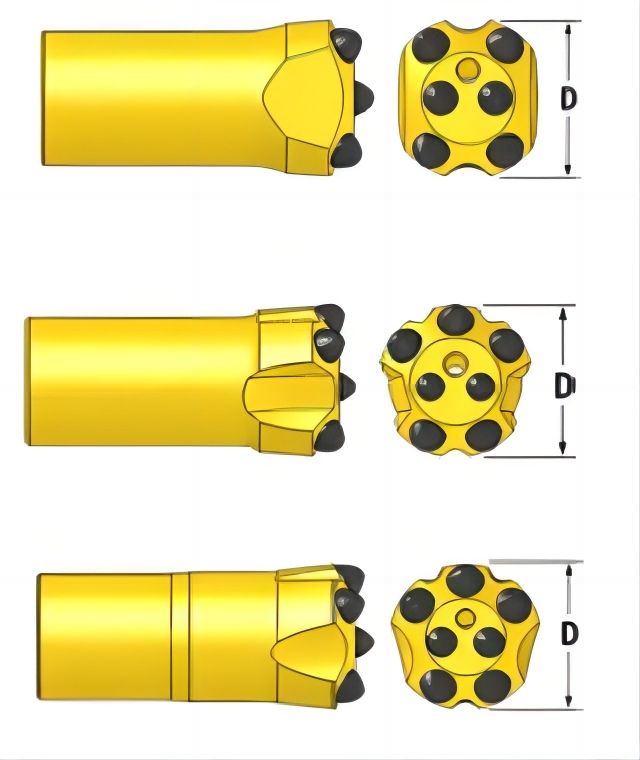

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Face Design | Application |

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt. |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

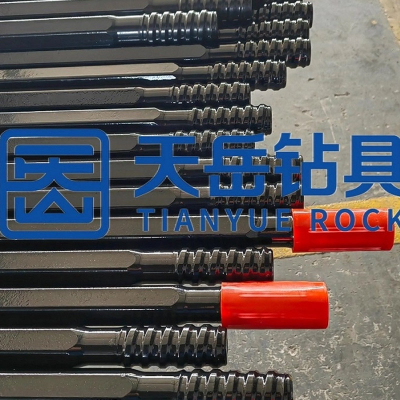

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

FAQ

Q1. How to control quality?

A: We have our own experienced team,there will be strict inspection and testing for every order before shipping out.

Q2. Fast delivery time:

A: Usually it takes 15-20 days for production.only 2 or 3 days if we have stock of your request size.

Q3. Shipping way:

A: Sample order: we suggest Courier express like DHL/UPS/TNT/FEDEX or by air

Bulk order: we suggest by air or by sea.

Q4. Competitive price:

A: Our factory can give the lowest price due to direct sale to customers without distributor!

If any other query, please do not hesitate to send me an inquiry. I will feedback asap.