Features:

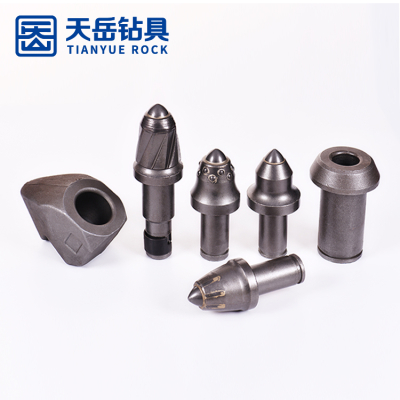

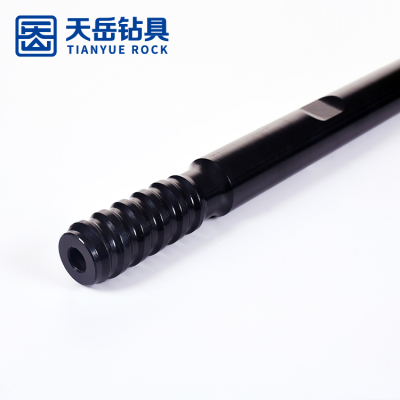

Independently researched and developed thread drill bits with high strength and good abrasion resistance.

Our team of engineers has successfully conducted independent research and development in the field of rock drilling bits, resulting in the creation of materials with exceptional strength and abrasion resistance. Through innovative techniques and rigorous testing, we have achieved significant advancements in material science.

Our button bits have been specifically designed to meet the demanding requirements of various industries, including manufacturing, aerospace, automotive, and oil and gas. With their high strength, they are able to withstand heavy loads and extreme conditions, ensuring durability and reliability in critical applications.

In addition, our Tophammer drill bit exhibit excellent abrasion resistance, which is crucial for industries where components are subjected to constant wear and tear. By combining the right blend of metals and employing advanced processing methods, we have successfully developed materials that can withstand abrasive forces without compromising their structural integrity.

What sets our rock drill tools apart is not only their exceptional mechanical properties but also their versatility.

We have successfully tailored our rock tools to meet specific industry needs, ensuring they perform optimally in a wide range of applications.

Furthermore, our commitment to continuous improvement drives us to continually refine and enhance our threaded bits, striving for even greater strength and abrasion resistance. Through ongoing research and development efforts, we aim to stay at the forefront of material innovation and provide our customers with the most advanced and reliable rock bits on the market.

In summary, our independently researched and developed button bits boast high strength and excellent abrasion resistance. With their superior mechanical properties and versatility, they offer an ideal solution for industries seeking durable and reliable materials for their applications.

Product |

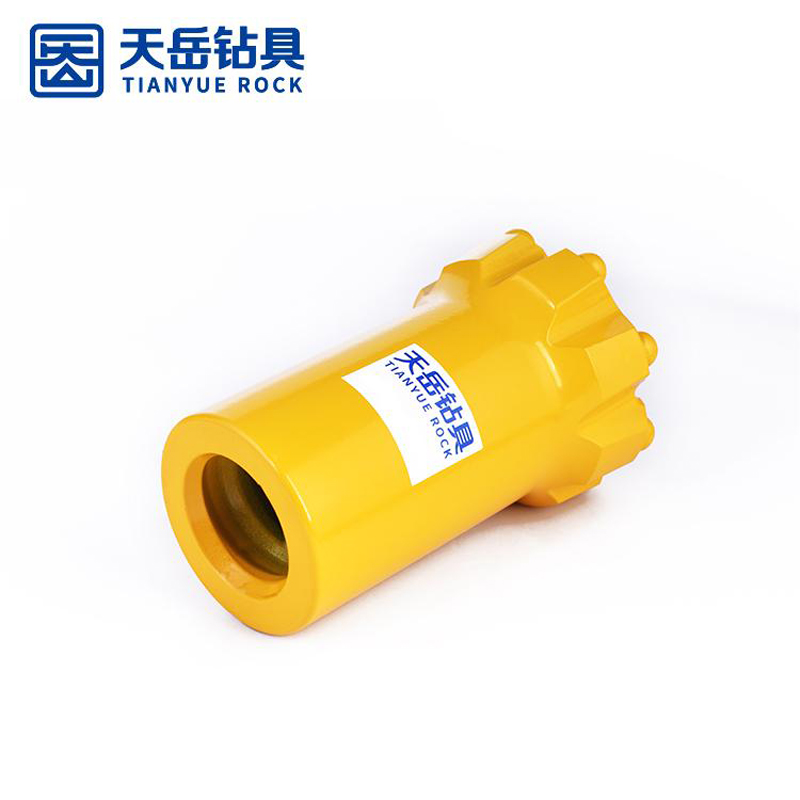

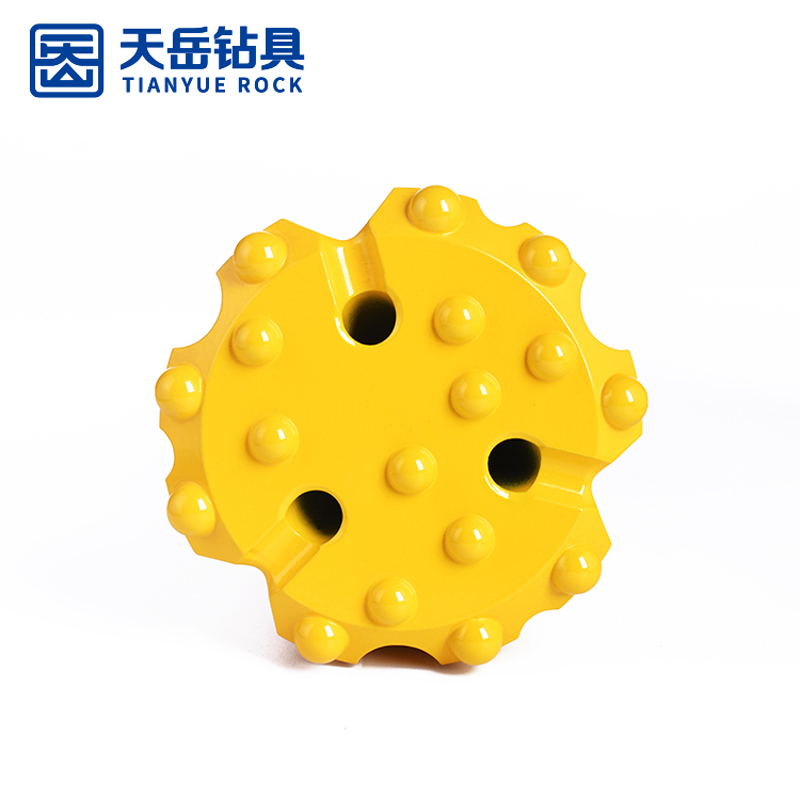

Button Bit |

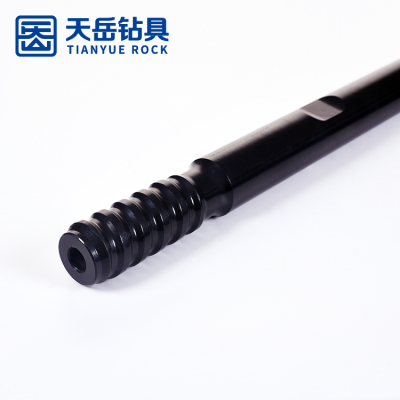

| Other Names | Button drill bit,Thread button bit,Thread drill bit,Rock drill bit,Top Hammer drill bit,Drill bit,Rock bit,Hard rock dilling tools,Rock dill tool,Rock tools,Top Hammer drilling tools,Mining drill bit |

| Material | 23CrNi3Mo |

| Application | Tunnelling, Mining, Quarrying, Ore Mining,Blasting and Infrastructure Construction,Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting. |

| Thread | R25, R28, R32, R35, R38, T38, T45, T51, ST58, ST68, GT60, SR28, SR35... |

| Bit Type | Thread Button Bit,Retrac Button Bit,Reaming Button Bit,Cross Bit,Chisel Bit |

| Skirt Design | Standard skirt, Retrac skirt, Straightrac skirt, Heavy duty skirt |

| Face Design | Flat face, Drop center face, Convex face, Reaming type, Cross type |

| Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons |

| Head Diameter | 28mm~152mm |

| Custom Design | Size,Color |

| Button bit | Diameter | No×button diameter | Flushing hole | Weight

approx kg | TIANYUE P/N |

| mm | inch | Front | Gauge | Angle | Front | Side |

| Spherical Buttons |

| 102 | 4 | 6×14 | 8×14 | 35° | 2 | 一 | 8.7 | 1431-102ST68-614/814-45-31 |

| 102 | 4 | 4×12.4×12 | 10×12 | 35° | 4 | 一 | 8.7 | 1432-102ST68-812/1012-45-31 |

| 105 | 4 1/8 | 6×14 | 8×14 | 35° | 2 | 一 | 8.9 | 1431-105ST68-614/814-45-31 |

| 105 | 4 1/8 | 4×14.2×12 | 8×14 | 35° | 4 | 一 | 8.9 | 1433-105ST68-614/814-45-31 |

| 110 | 4 3/8 | 6×14 | 8×16 | 35° | 2 | 一 | 9.4 | 1431-110ST68-614/816-45-31 |

| 110 | 4 3/8 | 4×14.2×14 | 8×16 | 35° | 4 | 一 | 8.9 | 1433-110ST68-614/816-45-31 |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | 一 | 9.6 | 1431-115ST68-614/816-45-31 |

| 115 | 4 1/2 | 4×14.2×14 | 8×16 | 35° | 4 | 一 | 9.5 | 1433-115ST68-614/816-45-31 |

| 115 | 4 1/2 | 4×14.4×14 | 10×14 | 35° | 4 | 一 | 9.5 | 1433-115ST68-814/1014-45-31 |

| 127 | 5 | 8×14 | 9×16 | 35° | 3 | 一 | 11 | 1431-127ST68-814/916-45-31 |

| 127 | 5 | 4×14.3×14 | 8×16 | 35° | 4 | 一 | 10.8 | 1433-127ST68-714/816-45-31 |

| 152 | 6 | 8×16 | 9×16 | 35° | 3 | 一 | 16.2 | 1431-152ST68-816/916-45-31 |

| 152 | 6 | 9×16 | 9×16 | 35° | 3 | 一 | 16.2 | 1431-152ST68-916/916-45-31 |

| 152 | 6 | 9×14.3×14 | 9×16 | 35° | 3 | 一 | 16.2 | 1433-152ST68-1214/916-45-31 |

| Parabolic Buttons |

| 102 | 4 | 6×14 | 8×14 | 35° | 2 | 一 | 8.7 | 1431-102ST68-614/814-45-51 |

| 102 | 4 | 4×12.4×12 | 10×12 | 35° | 4 | 一 | 8.7 | 1432-102ST68-812/1012-45-51 |

| 105 | 4 1/8 | 6×14 | 8×14 | 35° | 2 | 一 | 8.9 | 1431-105ST68-614/814-45-51 |

| 105 | 4 1/8 | 4×14.2×12 | 8×14 | 35° | 4 | 一 | 8.9 | 1433-105ST68-614/814-45-51 |

| 110 | 4 3/8 | 6×14 | 8×16 | 35° | 2 | 一 | 9.4 | 1431-110ST68-614/816-45-51 |

| 110 | 4 3/8 | 4×14.2×14 | 8×16 | 35° | 4 | 一 | 8.9 | 1433-110ST68-614/816-45-51 |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | 一 | 9.6 | 1431-115ST68-614/816-45-51 |

| 115 | 4 1/2 | 4×14.2×14 | 8×16 | 35° | 4 | 一 | 9.5 | 1433-115ST68-614/816-45-51 |

| 115 | 4 1/2 | 4×14.4×14 | 10×14 | 35° | 4 | 一 | 9.5 | 1433-115ST68-814/1014-45-51 |

| 127 | 5 | 8×14 | 9×16 | 35° | 3 | 一 | 11 | 1431-127ST68-814/916-45-51 |

| 127 | 5 | 4×14.3×14 | 8×16 | 35° | 4 | 一 | 10.8 | 1433-127ST68-714/816-45-51 |

| 152 | 6 | 8×16 | 9×16 | 35° | 3 | 一 | 16.2 | 1431-152ST68-816/916-45-51 |

| 152 | 6 | 9×16 | 9×16 | 35° | 3 | 一 | 16.2 | 1431-152ST68-916/916-45-51 |

| 152 | 6 | 9×14.3×14 | 9×16 | 35° | 3 | 一 | 16.2 | 1433-152ST68-1214/916-45-51 |

| Face Design | Application |

|

| Flat face button drill bits are suitable for all rock conditions, especially for the rock with higher hardness and higher abrasiveness. Such as granite and basalt |

| Convex Face button bits are designed for fast penetration rates in softer rock. |

|

| Drop center button drill bits are mainly suitable for the rock with low hardness, low abrasiveness, and good integrity. The bits can drill straighter holes. |

|

| Normal Skirt

For drilling in very hard and abrasive rock formations. |

|

| Retract Skirt

For drilling in loose,broken or fissured rock where it is difficult to retract the drill string due to the hole collapse. |

Actual pictures of drill bits

Threaded Drill Bits Retrac Button Bits Reaming Drill Bits Cross Bit Chisel Bit

Bit process flow

About US

Packing

FAQ

Q1: Which certifications do you have?

A: We have the ISO9001 and ISO14001 certifications.

Q2: Could you produce the abnormal items?

A: Yes, we accept OEM & ODM orders, as well as customized items.

Q3: Does your company provide samples?

A: Yes, we do provide samples as per your request for quality testin.

If any other query, please do not hesitate to send me an inquiry. I will feedback asap.