Design:

Trenching bits are designed to efficiently cut through soil and other materials during trenching operations. The design may include a cutting tip or insert that is crucial for breaking and excavating the ground.

Material:

The cutting tips of trenching bits are often made from hard and durable materials to withstand the abrasion and wear encountered during trenching. Common materials include tungsten carbide, which provides excellent hardness and wear resistance.

Bit Types:

Cup Teeth: These have a cup-shaped design and are effective for general-purpose trenching in soil.

Bullet Teeth: Featuring a bullet-shaped tip, these bits are suitable for penetrating harder ground or compacted soils.

Flat Teeth: With a flat cutting surface, these bits are designed for cutting through softer materials.

Trenching bits come in different types to suit various trenching applications:

Applications:

Utility Trenching: Excavating trenches for the installation of utility lines such as water pipes, gas lines, and electrical cables.

Pipeline Trenching: Creating trenches for the installation of pipelines for oil, gas, or other fluids.

Cable Trenching: Digging trenches for laying underground cables.

Trenching bits are used in various applications, including:

Compatibility:

Trenching bits are designed to be compatible with specific trenching equipment, such as trenchers or trenching machines. Ensuring proper fitment is crucial for the effective cutting and excavation of trenches.

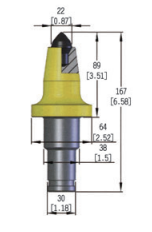

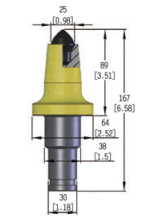

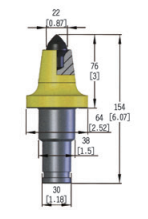

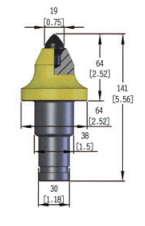

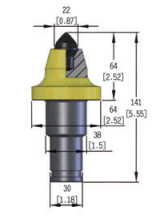

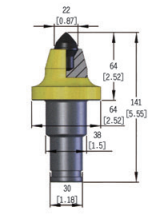

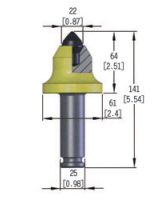

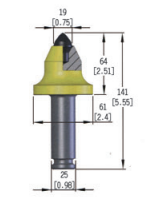

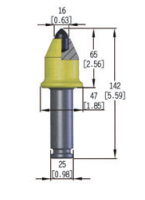

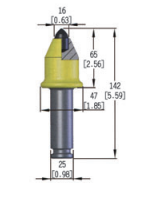

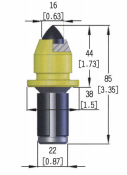

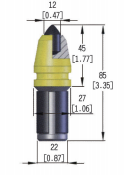

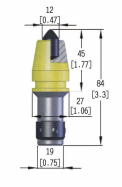

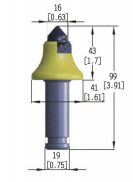

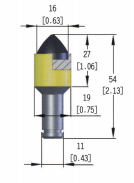

Sizes and Configurations:

Trenching bits come in various sizes and configurations to accommodate different trenching requirements. The selection of the appropriate size depends on factors such as soil type, desired trench width, and depth.

Durability:

Durability is a critical factor for trenching bits, considering the abrasive nature of soil and the potential presence of rocks or other obstacles. Tungsten carbide tips contribute to the longevity and wear resistance of the bits.

Maintenance:

Regular inspection and maintenance of trenching bits are essential for optimal performance. Checking for wear and replacing worn tips or bits contribute to the efficiency and longevity of the cutting tools.

Safety Considerations:

Safety is a priority in trenching operations. Proper training, adherence to safety protocols, and the use of appropriate personal protective equipment (PPE) are essential for the well-being of operators.

Trenching bits play a crucial role in creating precise and efficient trenches for various applications. The proper selection, use, and maintenance of these bits contribute to the success of trenching operations.